Synthetic method of vulcanizing agent 1,1-caprolactam disulfide

A technology for dithiodicaprolactam and a synthesis method, which is applied in the direction of organic chemistry and the like, can solve the problems of low product yield and melting point, high solvent toxicity, large amount of waste water, etc., and achieves less volatilization of solvent, cheap raw materials, and reduced waste water. The effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

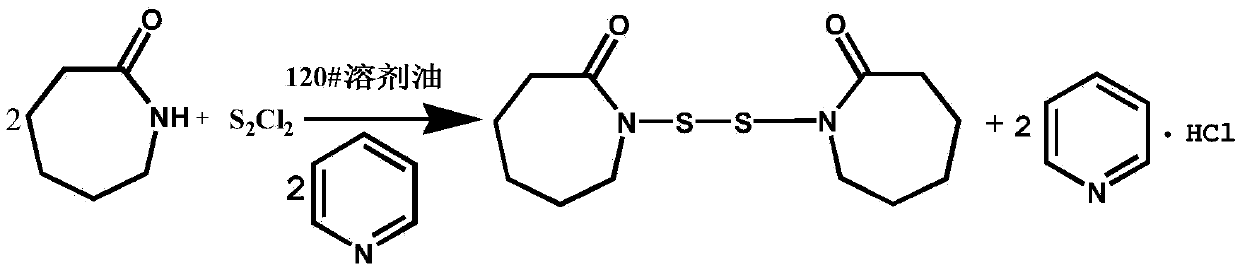

[0026] A synthetic method of vulcanizing agent 1,1-dithiodicaprolactam, the production process flow chart is shown in figure 1 As shown, the steps are as follows:

[0027] (1) After nitrogen replacement in the reactor, put in 900kg120# solvent oil, 210kg pyridine and 300kg caprolactam, after the temperature rises to 50°C, start to drop 170kgS 2 Cl 2 After 2 hours, the dropwise addition was completed, and after the addition was completed, stirring was continued at this temperature for 2.5 hours, and the mixture was obtained after the reaction was completed;

[0028] (2) Add a sodium hydroxide solution with a mass concentration of 15% in the kettle to adjust the pH value to 7, stir and heat up to 85°C, keep it standing at 85°C for half an hour, put the water phase clean, put the solvent oil phase into the cooling kettle, Cool down to 5°C with cooling water, and the product precipitates. After filtration, the wet product dithiodicaprolactam is obtained. The wet product is dried...

Embodiment 2

[0030] A kind of synthetic method of vulcanizing agent 1,1-dithiodicaprolactam, the steps are as follows:

[0031] (1) After nitrogen replacement in the reactor, put in 1252kg120# solvent oil, 219kg pyridine and 313kg caprolactam, after the temperature rises to 60°C, start to drop 170kgS 2 Cl 2 After 2 hours, the dropwise addition was completed, and after the addition was completed, stirring was continued at this temperature for 2.5 hours, and the mixture was obtained after the reaction was completed;

[0032] (2) Add a sodium hydroxide solution with a mass concentration of 14% in the kettle to adjust the pH value to 7, stir and heat up to 90°C, keep standing at 90°C for half an hour, put the water phase clean, put the solvent oil phase into the cooling kettle, Cool down to 10°C with cooling water, and the product precipitates. After filtration, the wet product dithiodicaprolactam is obtained. The wet product is dried to obtain 320kg of white solid, with a purity of 98.5%, a ...

Embodiment 3

[0034] A kind of synthetic method of vulcanizing agent 1,1-dithiodicaprolactam, the steps are as follows:

[0035] (1) After nitrogen replacement in the reaction kettle, put in 1000kg120# solvent oil, 209kg pyridine and 299kg caprolactam, after heating up to 45°C, start to drop 170kgS 2 Cl 2 After 2 hours, the dropwise addition was completed, and after the addition was completed, stirring was continued at this temperature for 2.5 hours, and the mixture was obtained after the reaction was completed;

[0036] (2) Add a sodium hydroxide solution with a mass concentration of 13% in the kettle to adjust the pH value to 7 and stir to raise the temperature to 87°C, keep it standing at 87°C for half an hour, put the water phase clean, put the solvent oil phase into the cooling kettle, Cool down to 6°C with cooling water, and the product precipitates. After filtration, the wet product dithiodicaprolactam is obtained. The wet product is dried to obtain 326 kg of white solid with a puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com