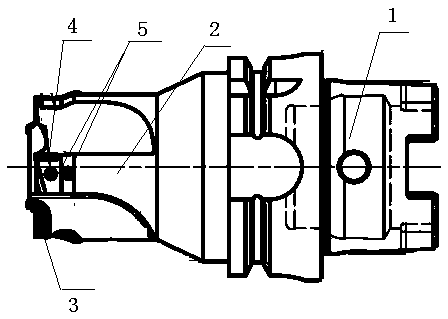

PCD adjustable reamer for machining cylinder body water hole blanking cap hole

An adjustable and water hole technology, which is applied in the direction of reamers, metal processing equipment, manufacturing tools, etc., can solve the problems of non-adjustable size of damaged teeth, inability to adjust roughness in time, single processing form, etc., to ensure service life, Good adhesion and good surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The PCD adjustable reamer for processing cylinder water hole plugging holes, wherein a protective layer is coated on the destroying edge, and the processing method of the protective layer is as follows:

[0035] (1) 20 parts by weight of nano-Si powder, 1.6 parts of nano-Ti powder, 6 parts of nano-C powder, 22 parts of nano-Al powder, 11 parts of nano-Zn powder, 7.8 parts of nano-CU powder, 17 parts of nano-Fe powder Adding into a ball mill and mixing for 4 hours to obtain nanoscale powder mixture A, the mixing temperature is 90°C;

[0036] (2) 25 parts by weight of polyurethane, 11 parts of 1.4 butanediol, 3 parts of carbodiimide, 5 parts of isocyanate, 3 parts of rare earth oxide, 15 parts of acrylic acid, 12 parts of antioxidant 1076, diacetyl Add 5 parts of mono- and diglycerides of tartrate into a mixer and stir for 1-3 hours to obtain mixture B, and the stirring temperature is 140°C;

[0037] (3) Mix nanoscale powder mixture A with a material temperature of 90°C ...

Embodiment 2

[0039] The PCD adjustable reamer for processing cylinder water hole plugging holes, wherein a protective layer is coated on the destroying edge, and the processing method of the protective layer is as follows:

[0040] (1) 25 parts by weight of nano-Si powder, 2.5 parts of nano-Ti powder, 8 parts of nano-C powder, 25 parts of nano-Al powder, 15 parts of nano-Zn powder, 10 parts of nano-CU powder, 20 parts of nano-Fe powder Adding into a ball mill and mixing for 4 hours to obtain nanoscale powder mixture A, the mixing temperature is 90°C;

[0041] (2) 28 parts by weight of polyurethane, 12 parts of 1.4 butanediol, 5 parts of carbodiimide, 8 parts of isocyanate, 3 parts of rare earth oxide, 18 parts of acrylic acid, 16 parts of antioxidant 1076, diacetyl Add 8 parts of tartrate mono-diglycerides into a mixer and stir for 1-3 hours to obtain mixture B, and the stirring temperature is 140°C;

[0042] (3) Mix nanoscale powder mixture A with a material temperature of 90°C and mixtu...

Embodiment 3

[0044] The PCD adjustable reamer for processing cylinder water hole plugging holes, wherein a protective layer is coated on the destroying edge, and the processing method of the protective layer is as follows:

[0045] (1) 15 parts by weight of nano-Si powder, 0.3 part of nano-Ti powder, 5 parts of nano-C powder, 20 parts of nano-Al powder, 8 parts of nano-Zn powder, 6.2 parts of nano-CU powder, 12 parts of nano-Fe powder Adding into a ball mill and mixing for 4 hours to obtain nanoscale powder mixture A, the mixing temperature is 90°C;

[0046] (2) 20 parts by weight of polyurethane, 10 parts of 1.4 butanediol, 1 part of carbodiimide, 2 parts of isocyanate, 1 part of rare earth oxide, 12 parts of acrylic acid, 5 parts of antioxidant 1076, diacetyl Add 3 parts of mono- and diglycerides of tartrate into a mixer and stir for 1-3 hours to obtain mixture B, and the stirring temperature is 140°C;

[0047] (3) Mix nanoscale powder mixture A with a material temperature of 90°C and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com