Rolling brush device of dust collector

A vacuum cleaner and roller brush technology, applied in the direction of suction nozzles, etc., can solve the problems of roller brush wear, difficulty in cleaning, motor blockage, etc., to achieve convenient cleaning, improve operation safety, and prevent roller brush wear and motor blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

[0027] Such as figure 1 As shown, the brush head 100 is provided with a rotatable rolling brush device 30. In this embodiment, the rolling brush device 30 is driven by a transmission motor (not shown) arranged in the brush head 100 to rotate, and the rolling brush The rotation of device 30 can loosen the dust on the work surface, and then the dust is sucked in the dust bag of the vacuum cleaner through the brush head 100. Meanwhile, the rolling brush device 30 in this embodiment can also store elongated garbage such as hair and thread ends.

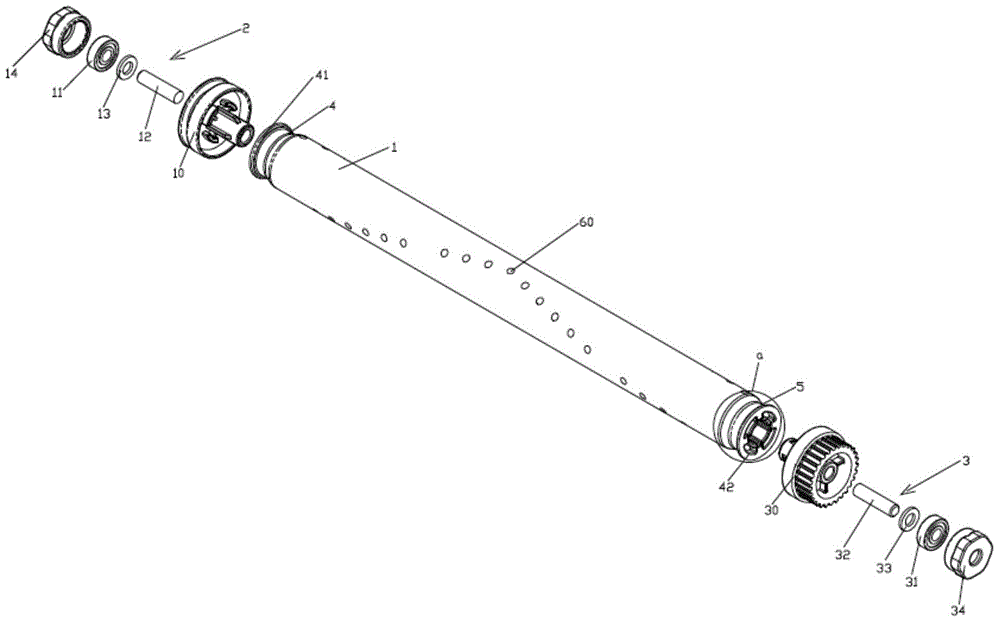

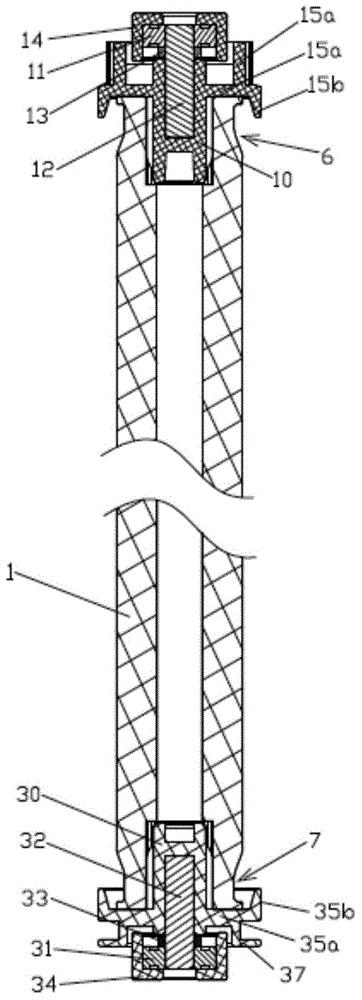

[0028] further reference figure 2 and image 3 The rolling brush device 30 of the present invention includes a rolling brush body 1, and a rotating part 2 and a transmission part 3 respectively detachably arranged at both ends of the rolling brush body 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com