Engaging-type ground wire clamp

A grounding wire clamp and grounding wire technology, which is applied in the direction of connection, conductive connection, electrical connection seat, etc., can solve the problems of large elastic coefficient of grounding wire clamp tension spring, blocking operators, increasing operating risks, etc., to reduce physical energy consumption, increase the contact area, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

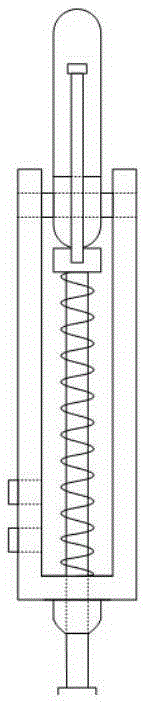

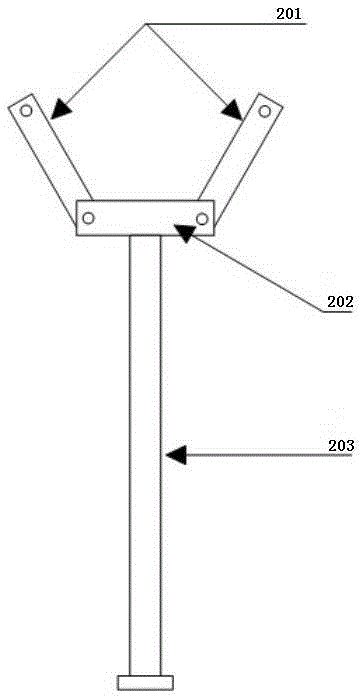

[0025] like figure 1 and figure 2 As shown, the bite-type grounding clamp is composed of four parts: clamping device 100, linkage device 200, booster spring 400, and bracket 300. Except for booster spring 400, other parts are made of aluminum with low density and high conductivity. The booster spring 400 is arranged in the bracket 300 , the linkage device 200 passes through the booster spring 400 and is fixed by the bracket 300 , and controls the clamping device 100 to engage.

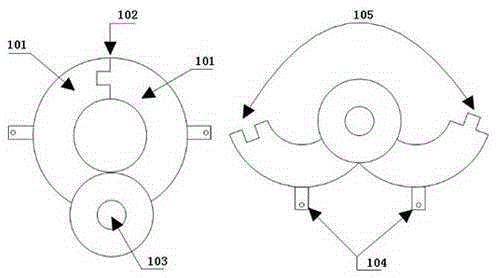

[0026] like image 3 As shown, the clamping device 100 is composed of three parts, which are respectively the connecting shaft 103, the wire clamp ring 101 and the linkage buckle 104, and one end of the two arc-shaped wire clamp rings 101 is connected with the connecting shaft 103, so that the constituted The diameter of the wire clamp ring 101 is large enough to completely clamp the wire, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com