A kind of flexible cable for drag chain

A flexible cable and drag chain technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems affecting the performance of cables, human and environmental hazards, internal structure damage, etc., to reduce surface transfer impedance, aging resistance, etc. Outstanding performance and the effect of reducing heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

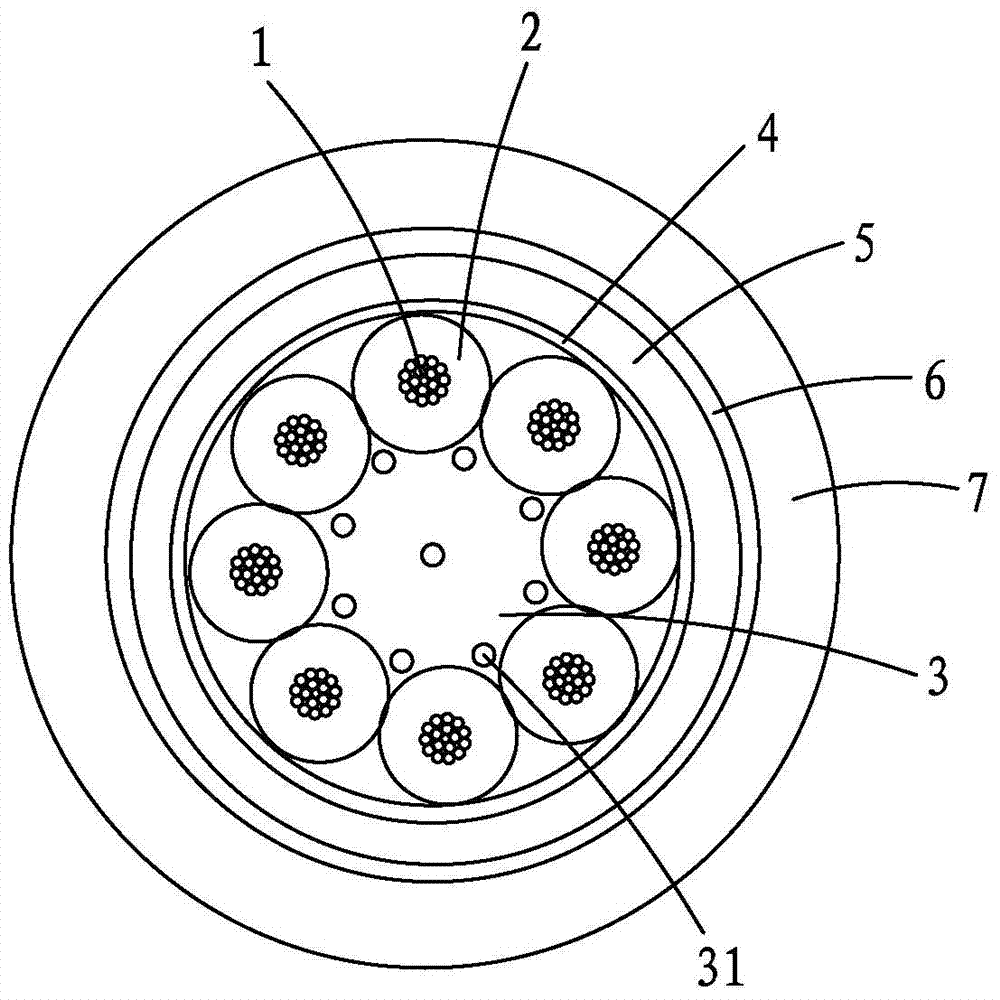

[0027] see figure 1 As shown, the embodiments of the present invention will be described in detail.

[0028] like figure 1 As shown, a flexible cable for drag chains, the cable includes a conductor 1, an insulating layer 2, a polypropylene filling rope 3, a non-woven fabric tape 4, an inner lining layer 5, a metal braided shielding layer 6 and an outer sheath 7, The conductor 1 is extruded with an insulating layer 2 to form an insulated wire core, and a cabled wire core is formed by twisting a plurality of insulated wire cores around a plurality of polypropylene filling ropes 3, and the non-woven fabric tape 4 is wrapped On the cabled core, the non-woven fabric tape 4 outwardly includes an inner liner 5 , a metal braided shielding layer 6 , and an outer sheath 7 .

[0029] The conductor: it is formed by twisting a plurality of fine and soft round copper wires in the left direction with a pitch ratio not greater than 15 to 25 times. The size of the paralleling die is about 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com