Screen-printed electrode based on graphene conductive ink and processing method thereof

A screen printing electrode and conductive ink technology, applied in the direction of material electrochemical variables, etc., can solve the problems of cumbersome preparation process, high preparation cost, limited improvement of electron transfer and catalytic activity, and achieve improved sensitivity, large specific surface area, Effect of improving electron transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

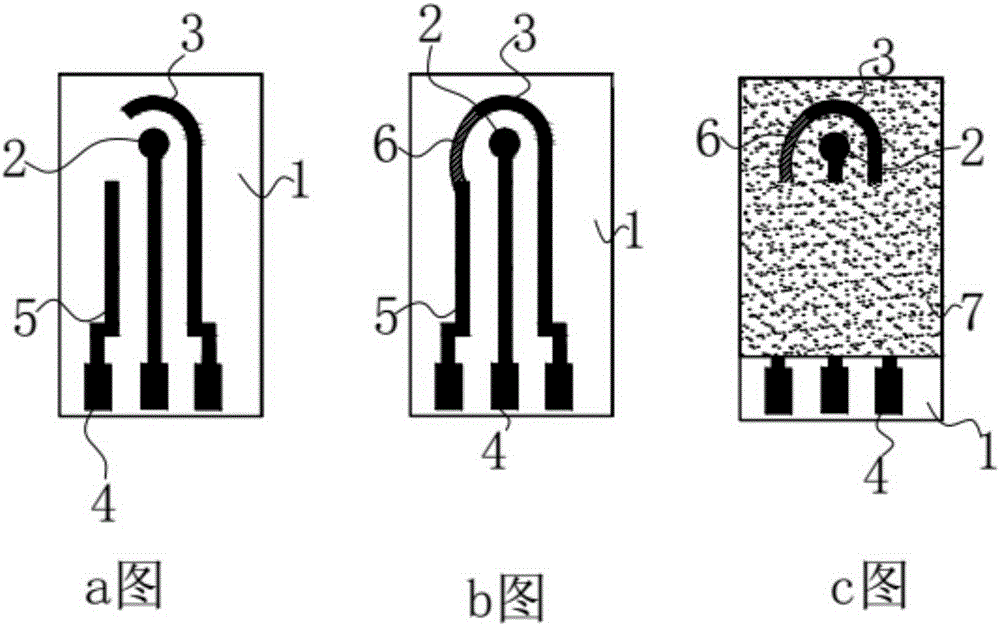

[0030] Example 1, such as figure 1 As shown, the present embodiment provides a screen printing electrode based on graphene conductive ink, including a substrate. The shape of the substrate is the shape of a common substrate in the market. Printed insulating materials can be used for electrode substrates, preferably polyvinyl chloride (PVC), polytetrafluoroethylene (PTFE) or PET plastics, etc., and the substrates are printed with working electrodes, counter electrodes and conductive leads (the specific layout is as follows: figure 1 As shown in Figure a, this type of layout is also a common layout in the market, and of course other layouts can also be used), the screen printing electrode provided in this embodiment is a three-electrode structure, the working electrode and the conductive lead and The electrical connection between the counter electrode and the conductive lead wire, and the lead wire between the working electrode and the conductive lead wire and the counter electr...

Embodiment 2

[0034] Embodiment 2: This embodiment provides a kind of preparation method of the screen printing electrode based on graphene conductive ink:

[0035]In the embodiment process provided by the present invention, the screen printing machine used is a plane screen printing machine produced by Qingdao Ou Ruier Automation Equipment Co., Ltd., and the model is ORE-2030. In this embodiment, some steps are also combined with the screen printing Some functions of the screen printing machine, and the structure of other screen printing machines may be inconsistent with the structure provided in this embodiment, but it cannot affect the scope of protection of the present invention.

[0036] 1. Substrate pretreatment

[0037] (1) Ultrasonic cleaning of the cut PVC substrate with acetone for 15 minutes each time to remove dirt on the surface, and then ultrasonic cleaning with absolute ethanol once for 5 minutes each time, and drying naturally.

[0038] 2. Electrode printing

[0039] (2) w...

Embodiment 3

[0061] Embodiment 3: This embodiment provides a kind of preparation method of the screen printing electrode based on graphene conductive ink:

[0062] 1. Substrate pretreatment

[0063] (1) Ultrasonic clean the cut PTFE substrate twice with acetone for 10 minutes each time to remove the dirt on its surface, then ultrasonically clean it twice with absolute ethanol for 10 minutes each time, and let it dry naturally.

[0064] 2. Electrode printing

[0065] (2) will be used for printing figure 1 The stencil of the pattern in picture a is fixed on the horizontal workbench of the screen printing machine, the distance between the stencil and the horizontal workbench is 3cm, and the squeegee angle is adjusted to 50 degrees.

[0066] (3) Put the naturally dried substrate on the surface of the workbench, turn on the air pump, and use negative pressure adsorption to ensure that the substrate is fixed and prevent the misalignment problem caused by the movement of the substrate during pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com