An online real-time monitoring device and monitoring method for TBM hob wear

A real-time monitoring and hob technology, applied in measuring devices, electrical devices, instruments, etc., can solve problems such as hob wear monitoring, achieve strong wear resistance, high sensitivity of electromagnetic signals, and ensure measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

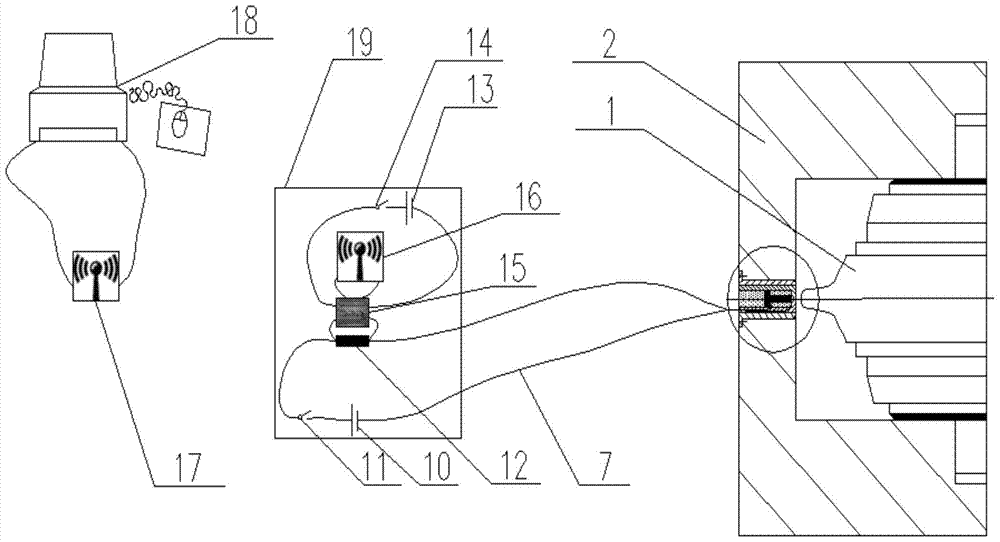

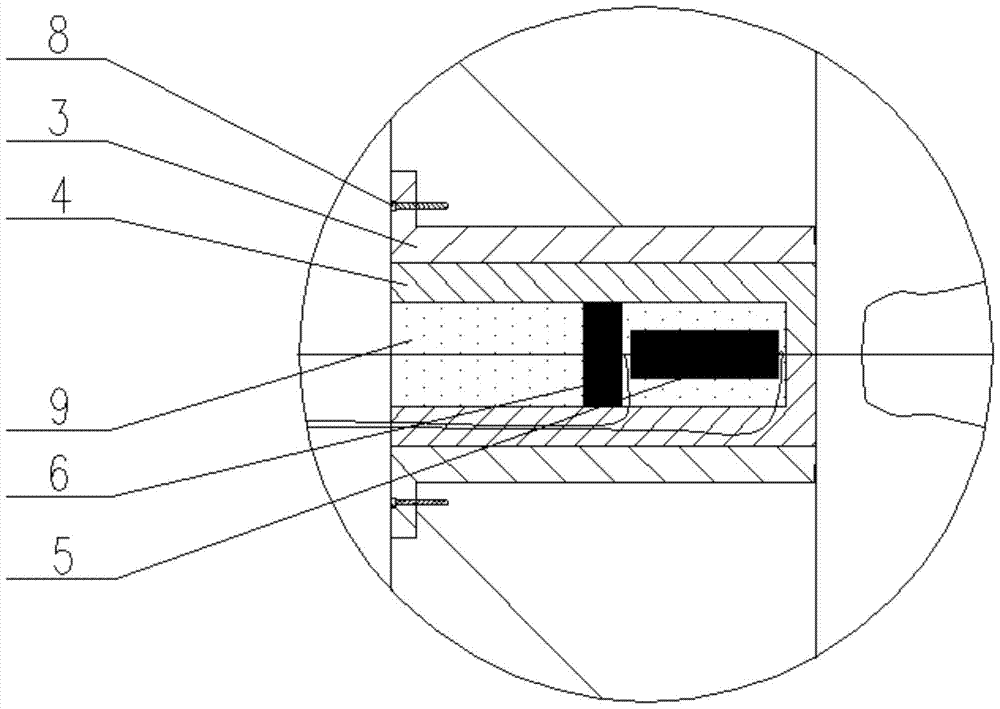

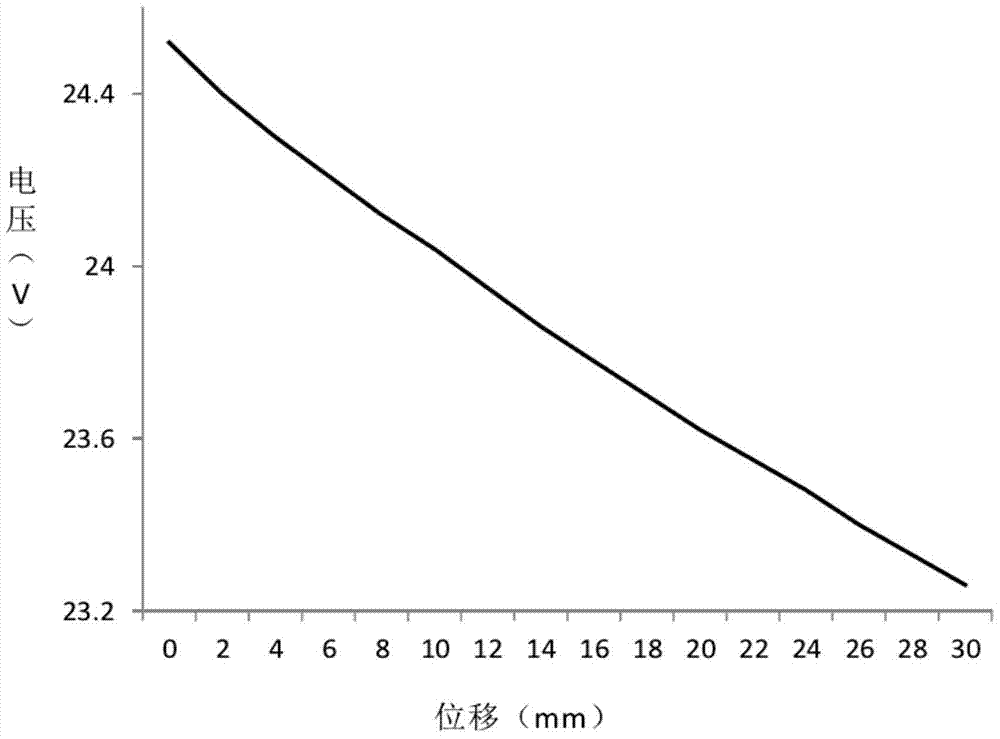

[0024] Such as Figure 1 to Figure 2 A TBM hob wear online real-time monitoring device is shown, comprising a tool seat 2, a hob 1 located on the tool seat 2, a data acquisition module and a data processing module, and the data acquisition module includes a permanent magnet 6, a magneto-sensitive Z The element 5 and the data collector, a detachably connected sensor base 3 is provided in the position facing the hob 1 in the knife seat 2, and a sealed and fitted tetrafluoroethylene protective shell 4 is provided in the sensor base 3, The permanent magnet 6 and the magnetosensitive Z element 5 are fixed in the tetrafluoroethylene protective shell 4 through the AB glue 9;

[0025] Described data acquisition device comprises A power supply 10, A switch 11, fixed-value resistor 12, single-chip processor 15 and wireless transmitting module 16, and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com