Gas single-head large pot stove

A large pot and gas technology, applied in the field of kitchen utensils, can solve the problems of gas safety accidents, large burner leakage, etc., and achieve the effect of sensitive response and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

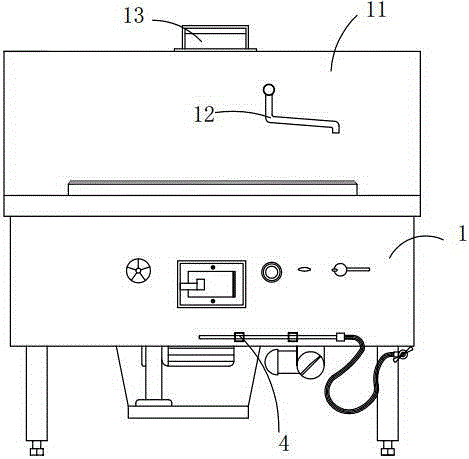

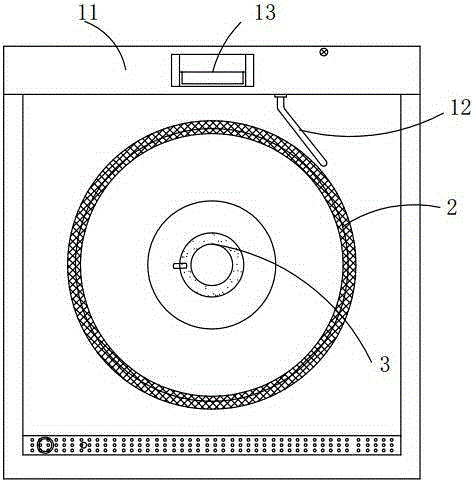

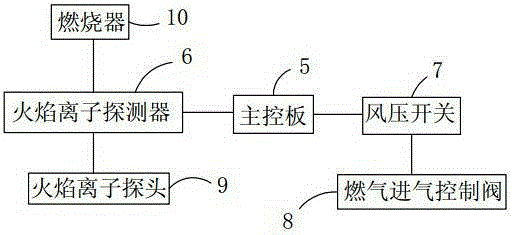

[0012] 1 is the furnace frame, 2 is the furnace enclosure, 3 is the burner head, 4 is the ignition and flameout safety control device, 5 is the main control board, 6 is the flame ion detector, 7 is the wind pressure switch, 8 is the gas inlet control valve, 9 is a flame ion probe, 10 is a burner, 11 is a backrest, 12 is a swing faucet, and 13 is a chimney.

[0013] see Figure 1 to Figure 3 A gas single-burner large cooker includes a hob 1 , a furnace enclosure 2 , a burner 3 , and a safety control device 4 for ignition and extinguishment arranged on the hob 1 . The ignition safety control device 4 is arranged close to the burner 3, and it includes a main control board 5, a flame ion detector 6 and a wind pressure switch 7 connected to the main control board 5 respectively. The wind pressure switch 7 is connected with a gas intake control valve 8 for controlling the opening of the gas intake control valve 8 . The flame ion detector 6 is used to detect whether there is a flam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com