Hydrostatic pressure supporting device with rectangular cavity

A static pressure support and rectangular cavity technology, which is applied in the field of rectangular cavity hydrostatic support devices, can solve the problems of low support stiffness and insufficient bearing capacity, and achieve the effects of improved support stiffness, large static pressure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

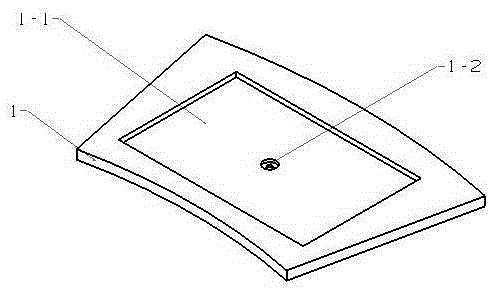

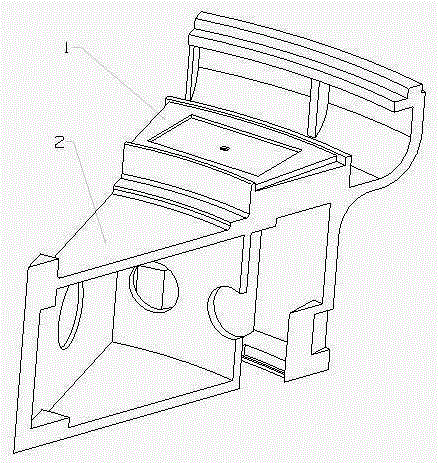

[0007] Combined with the accompanying drawings of each specification, a rectangular oil pad 1 of a hydrostatic thrust bearing is mainly the main structure of the oil pad. Its shape is fan-shaped, and the upper end of the oil pad is a rectangular oil chamber 1-1. The oil inlet 1-2 hydraulic oil flows into the oil chamber 1-1 through the oil inlet 1-2. The total thickness of the oil pad is 15mm, and the depth of the oil cavity is 3mm.

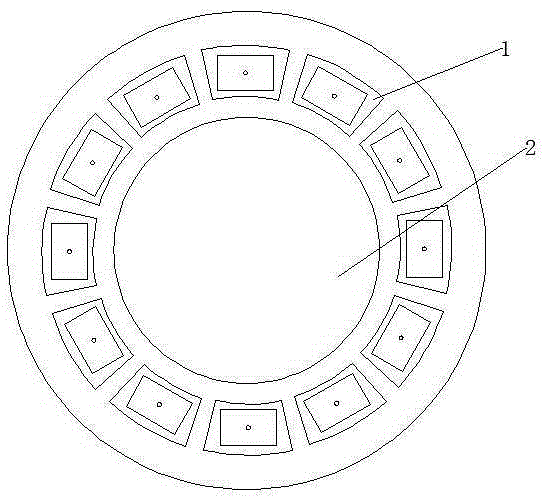

[0008] Working principle: 12 identical oil pads 1 are evenly arranged on the base 2 during work, and then the rotary table of the machine tool is installed on the rectangular oil pad. When the oil pump is started, the hydraulic oil is input to the oil through the oil inlet 1-2. Chamber 1-1, when the pressure formed by the hydraulic oil in the oil chamber 1-1 is enough to push the external load, the rotary table will be jacked up, resulting in a thin oil film formed between the oil pad and the surface of the rotary table, and the machine tool will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com