Drill bit used for high air-pressure down-the-hole drill hammer with capability of penetrating reinforced concrete

A reinforced concrete and down-the-hole drilling technology, which is applied to drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of easily broken spherical column tooth heads, reduced drilling efficiency, and increased construction costs, and achieves improved drilling performance. The effect of speed and service life, reduction of repeated punching and crushing, and improvement of drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the drawings, and the following embodiments can enable those skilled in the art to better understand the present invention, but do not limit the present invention in any form.

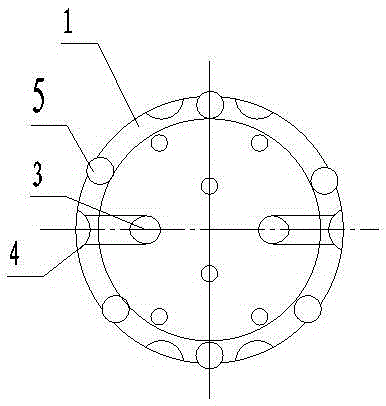

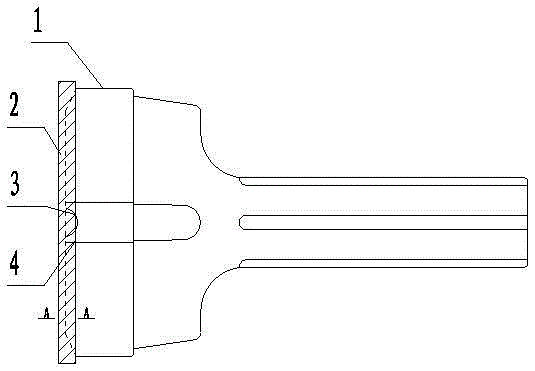

[0020] The present invention is improved on the basis of the existing high wind pressure down-the-hole drill hammer. The same as the prior art, it includes a drill body 1, an exhaust hole 3, and a slag discharge groove 4. The difference is that the drill bit There are inlaid strip-shaped alloy tooth heads 2 on the head plane of the body 1, and there are 2 to 10 strip-shaped alloy tooth heads 2 with equal central angles arranged radially on the drill bit body plane.

[0021] Such as image 3 , Figure 4 , Figure 5 As shown, it includes a drill bit body 1, a strip-shaped alloy tooth head inlaid on the plane of the drill bit body head 2, two exhaust holes are arranged symmetrically on the large plane head in the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com