Method for preparing high-purity topological insulator YbB6 single crystal

A topological insulator and single crystal technology, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of affecting topological properties, small single crystal size, easy to bring in impurity aluminum elements, etc., to achieve high quality and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

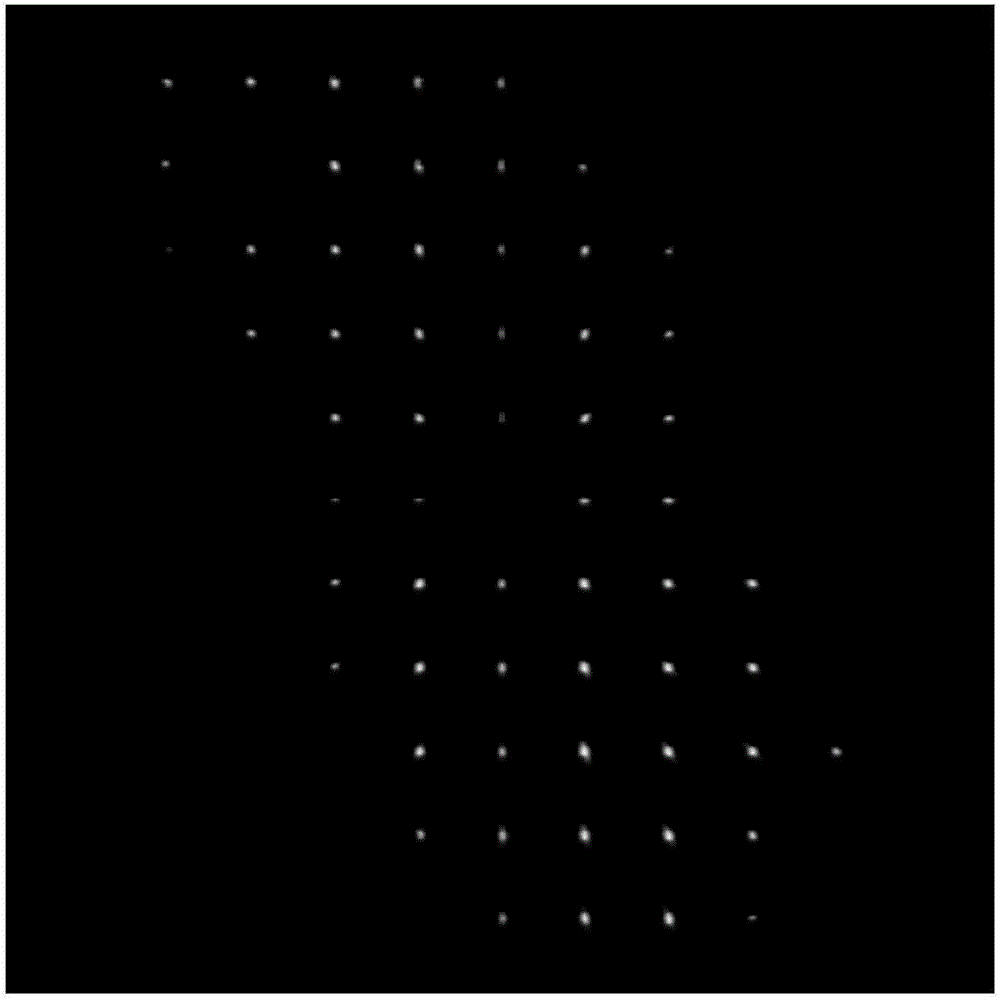

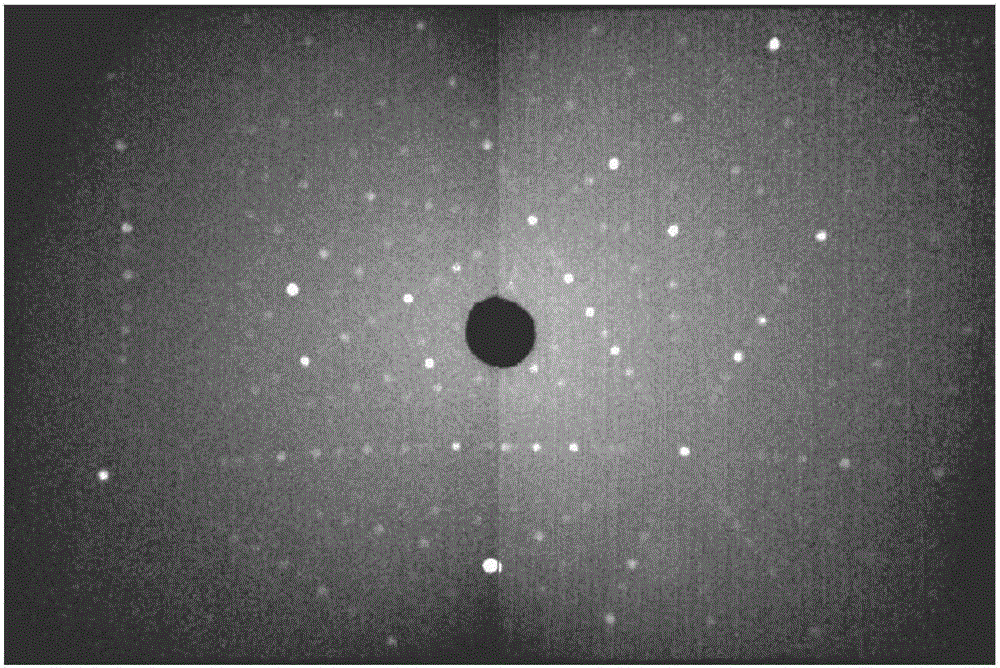

Image

Examples

Embodiment 1

[0018] 1) YbB 6 Put the powder into a graphite mold after ball milling and mixing; place the mold in the sintering chamber of a plasma activation sintering machine, and sinter under a vacuum condition with a total pressure lower than 5Pa; heat up to 1300°C at a heating rate of 80°C / min, Insulate for 15 minutes, and cool to room temperature with the furnace to obtain YbB 6 polycrystalline rod;

[0019] 2) Using an optical zone melting furnace, YbB with a diameter of 5mm 6 The polycrystalline rod is used as the seed crystal and the material rod for the first zone melting purification; after the equipment is vacuumed below 1Pa, it is rushed into the flowing H 2 The content (volume content, the same below) is 5% H 2 / Ar reduction mixed gas until the pressure rises to 0.2MPa, the gas flow rate is 1.5L / min, and the power of the furnace in the 20min zone is increased to melt the seed crystal and material rod and form a stable melting zone. In order to make the melting zone more un...

Embodiment 2

[0022] 1) YbB 6 Put the powder into a graphite mold after ball milling and mixing; place the mold in the sintering chamber of a plasma activation sintering machine, and sinter under vacuum conditions with a total pressure lower than 5Pa; heat up to 1350°C at a heating rate of 100°C / min, Keep it warm for 12 minutes, and cool down to room temperature with the furnace to get YbB 6 polycrystalline rod;

[0023] 2) Using an optical zone melting furnace, YbB with a diameter of 8mm 6 The polycrystalline rod is used as the seed crystal and the material rod for the first zone melting purification; after the equipment is vacuumed below 1Pa, it is rushed into the flowing H 2 5% H 2 / Ar reduction mixed gas until the pressure rises to 0.2MPa, the gas flow rate is 1.8L / min, and the power of the furnace in the 20min zone is increased to melt the seed crystal and material rod and form a stable melting zone. In order to make the melting zone more uniform, the seed crystal and material The ...

Embodiment 3

[0026] 1) YbB 6 Put the powder into a graphite mold after ball milling and mixing; place the mold in the sintering chamber of a plasma activation sintering machine, and sinter under a vacuum condition with a total pressure lower than 5Pa; heat up to 1100°C at a heating rate of 120°C / min, Insulate for 10 minutes, and cool to room temperature with the furnace to obtain YbB 6 polycrystalline rod;

[0027] 2) Using an optical zone melting furnace, YbB with a diameter of 10mm 6 The polycrystalline rod is used as the seed crystal and the material rod for the first zone melting purification; after the equipment is vacuumed below 1Pa, it is rushed into the flowing H 2 5% H 2 / Ar reduction mixed gas until the pressure rises to 0.2MPa, the gas flow rate is 1.8L / min, and the power of the furnace in the 20min zone is increased to melt the seed crystal and material rod and form a stable melting zone. In order to make the melting zone more uniform, the seed crystal and material The rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com