Saccharomycete for high-yield production of ethyl acetate under low temperature and application thereof

A low-temperature condition, ethyl acetate technology, applied in the field of bioengineering, can solve the problems of many types of metabolites, high fermentation temperature, difficult process, etc., and achieve the effects of reducing fermentation temperature, increasing ethyl acetate content, and considerable economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

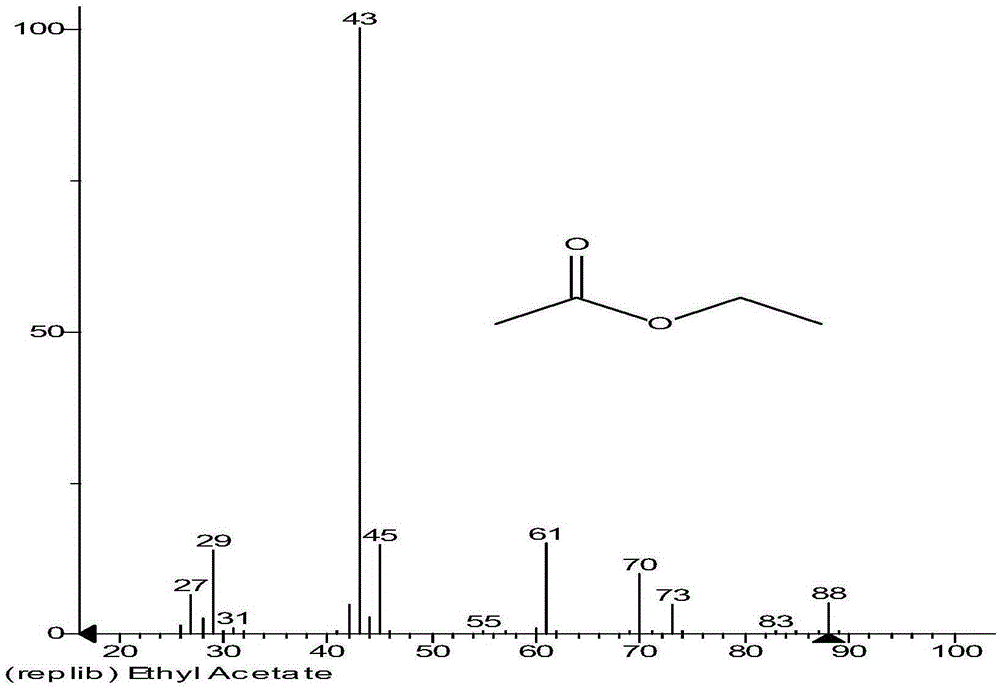

[0019] The screening of embodiment 1 ester-producing yeast

[0020] Grind the koji medicine and fermented unstrained spirits with a mortar, weigh 10g to 100ml of sterile normal saline, and vibrate at 150r / min for 30min to obtain the bacterial suspension, perform ten-fold serial dilution, and spread the dilution on the primary screening culture Base, select the ratio of the diameter of the transparent circle and the diameter of the colony to be a large colony, that is, a strain with significant ester production. Then the bacterial strain was transferred, and the shake flask fermentation was re-screened. The ester type of the fermentation liquid was determined by the HS-SPME-GC-MS method, and the ethyl acetate content of the fermentation liquid was determined by the method for determining the total esters of liquor stipulated in GB / T10345-2007. The strains with strong ability of producing ethyl acetate were screened.

[0021] The initial screening culture conditions for ester p...

Embodiment 2

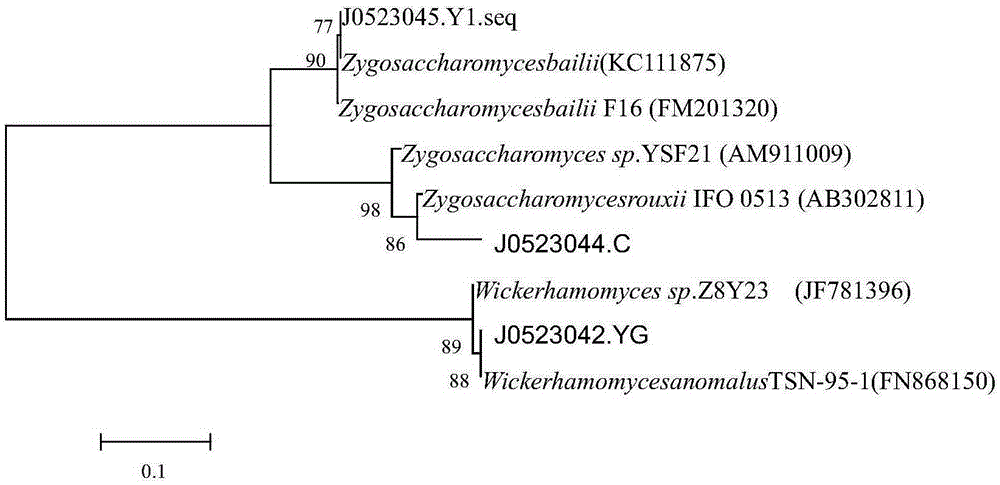

[0027] Example 2 Ethyl acetate-producing yeast and its molecular biology identification

[0028] The obtained ethyl acetate-producing yeast was identified by molecular biology, and the 26SrDNA fragments of the strains were amplified with yeast-specific classification and identification primers, and detected by gel electrophoresis. Sequencing comparison was then carried out to determine the species of the screened yeast. The strain was deposited in the General Microorganism Center of China Committee for Culture Collection of Microorganisms, and the yeast species and preservation number were: Wickerhamomycesanomalus (Wickerhamomycesanomalus) CGMCCNO: 10370.

[0029] The process of confirming the species of yeast is as follows:

[0030] Identification of 26SrDNA sequence homology of isolated strains: Extraction of yeast DNA: Inoculate the yeast in liquid YPD medium after activation, and after cultivating on a shaker at 28°C for 12 hours, take a small amount of bacteria into a st...

Embodiment 3

[0035] The acid resistance test of embodiment 3 yeast strains

[0036] Adjust the pH of the YPD liquid medium to 1.0-7.0, increase with a gradient of pH0.5, do three parallels for each gradient, inoculate 10% (V / V) yeast suspension, at 30°C, 150r / min, after culturing for 24h , Use a microplate reader to measure the turbidity of the culture medium under the condition of 600nm wavelength to determine the growth of the bacteria. The acid resistance results of the strains are shown in Table 1 below.

[0037] Table 1 strain acid resistance (OD 600 value)

[0038] pH

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

OD 600

0.002

1.085

1.291

1.341

1.335

1.403

1.403

1.425

1.421

1.417

1.433

[0039] Table 1 shows the OD of the strains at pH2.5 600 reached 1.085, indicating that the strain can grow normally under the environment of pH2.5,

[0040] And with the increase of pH, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com