Preparation method of modified carboxylic acid water reducer

A water-reducing agent and modification technology are applied in the field of preparation of modified carboxylic acid-based water-reducing agents, which can solve the problem of low slump retention effect and achieve the effect of improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

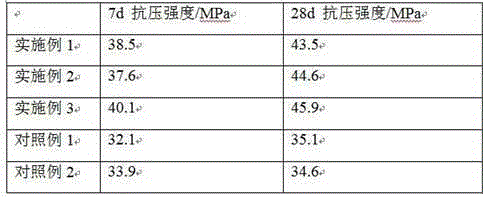

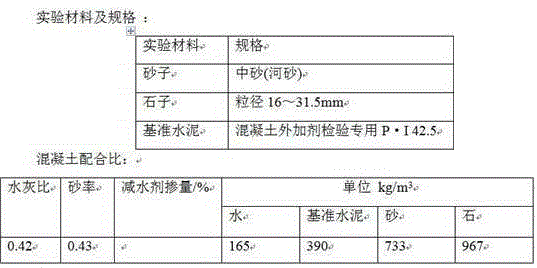

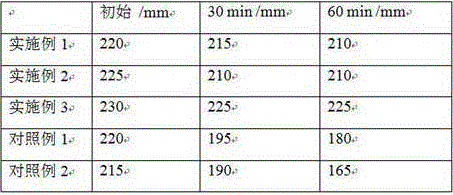

Examples

Embodiment 1

[0020] The preparation method of water reducer:

[0021] Step 1, by weight, 5 parts of acrylamide, 15 parts of sodium lignosulfonate, 20 parts of maleic anhydride, 3 parts of methacrylic acid, 3 parts of dibutyl itaconate, 3 parts of dibutyl maleate 3 parts, 4 parts of KH-550 silane coupling agent, 2 parts of catalyst concentrated sulfuric acid, add in the reaction vessel with water bath; Then add 70 parts of deionized water in the reaction vessel, then pass nitrogen to the reaction vessel to deoxygenate and Perform a stirring reaction, the reaction temperature is 80°C; the reaction time is 2h;

[0022] Step 2, in parts by weight, add 30 parts of isopentenyl polyoxyethylene ether, 3 parts of maleic anhydride, 4 parts of cyclohexyl methacrylate, 5 parts of acrylic acid, 10 parts of maleic anhydride, 8 parts of sodium methacrylate, 5 parts of dimethylaminoethyl methacrylate, 5 parts of dimethyl azobisisobutyrate initiator, and then continue to flow nitrogen, and start the react...

Embodiment 2

[0025] Step 1, by weight, 8 parts of acrylamide, 30 parts of sodium lignosulfonate, 40 parts of maleic anhydride, 5 parts of methacrylic acid, 6 parts of dibutyl itaconate, 6 parts of dibutyl maleate 5 parts, 6 parts of KH-550 silane coupling agent, 4 parts of catalyst concentrated sulfuric acid, add in the reaction container that has water bath; Perform a stirring reaction, the reaction temperature is 90°C; the reaction time is 7h;

[0026] Step 2, in parts by weight, add 50 parts of isopentenyl polyoxyethylene ether, 5 parts of maleic anhydride, 6 parts of cyclohexyl methacrylate, 10 parts of acrylic acid, 15 parts of maleic anhydride, 15 parts of sodium methacrylate and 10 parts of dimethylaminoethyl methacrylate, 10 parts of dimethyl azobisisobutyrate initiator, then continue to flow nitrogen, start the reaction under stirring , the reaction temperature is 70°C, and the reaction time is 8 hours. After the end, the stirring is stopped and the nitrogen flow is stopped; afte...

Embodiment 3

[0029] Step 1, by weight, 6 parts of acrylamide, 20 parts of sodium lignosulfonate, 30 parts of maleic anhydride, 4 parts of methacrylic acid, 5 parts of dibutyl itaconate, 5 parts of dibutyl maleate 4 parts, 5 parts of KH-550 silane coupling agent, 3 parts of catalyst concentrated sulfuric acid, add in the reaction vessel with water bath; Then add 75 parts of deionized water in the reaction vessel, then pass nitrogen to deoxygenate in the reaction vessel and Perform a stirring reaction, the reaction temperature is 85°C; the reaction time is 5h;

[0030] Step 2, in parts by weight, add 40 parts of isopentenyl polyoxyethylene ether, 4 parts of maleic anhydride, 5 parts of cyclohexyl methacrylate, 8 parts of acrylic acid, 12 parts of maleic anhydride, 11 parts of sodium methacrylate, 8 parts of dimethylaminoethyl methacrylate, 8 parts of dimethyl azobisisobutyrate initiator, and then continue to flow nitrogen, and start the reaction under stirring , the reaction temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com