Scaling powder used for high-precision nanometer soldering paste

A nano-welding and flux technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of not meeting the requirements, not fully adapting to new needs, etc., to improve printing life, improve welding Efficiency, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

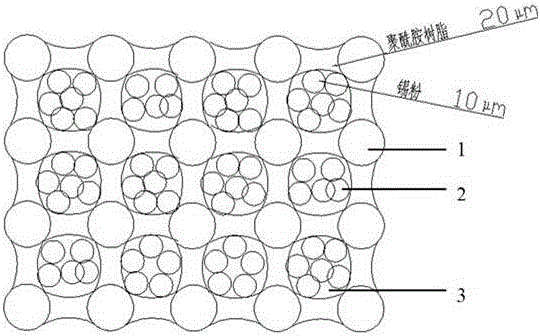

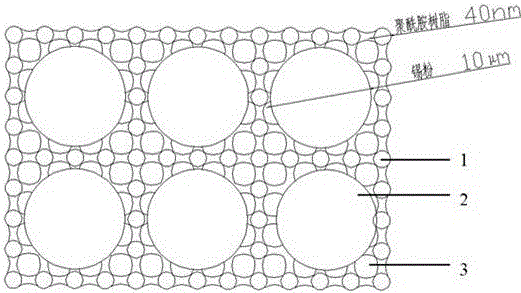

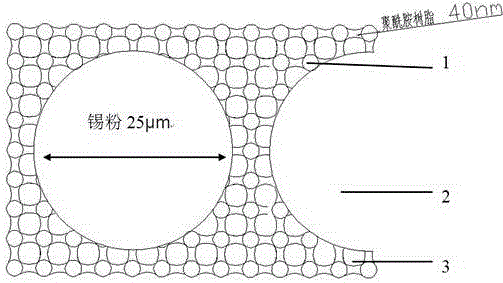

Image

Examples

Embodiment 1

[0035] 1. Take 4g of polyamide resin, 10g of ethanol, and 0.14g of hydroxyethyl cellulose into the autoclave, heat to 150~170°C while stirring continuously until the polyamide resin is completely dissolved; Cool down to 70°C at a min speed, stop stirring and cool down to room temperature, take out the materials in the autoclave, separate the powder and solvent, and obtain 4g of pure polyamide resin nanoparticles after drying;

[0036] 2. Add 28.5g of diethylene glycol monooctyl ether, 35g of perhydrorosin, and 15g of disproportionated rosin into the reaction vessel, heat to 115°C and stir until the rosin is completely dissolved in diethylene glycol monooctyl ether; cool down to 75°C , add 3g of 16 acid, 2.5g of 24 acid, 2g of triethanolamine, 3.5g of benzotriazole, stir well until mixed evenly; cool to 20°C, add 5.5g of polyoxyethylene glyceryl ether, 4g of polyamide resin nanopowder, Stir and evacuate until it is uniformly mixed, and grind the solid particles in the uniformly...

Embodiment 2

[0038] 1. Take 5g of polyamide resin, 11.7g of ethanol, and 0.17g of hydroxyethyl cellulose into the autoclave, heat to 150~170°C while stirring continuously until the polyamide resin is completely dissolved; continue to stir and heat at 2°C Cool down to 70°C at a speed of / min, stop stirring and cool down to room temperature, take out the materials in the autoclave, separate the powder and solvent, and obtain 5g of pure polyamide resin nanoparticles after drying;

[0039] 2. Add 30g of triethylene glycol monobutyl ether, 34g of perhydrorosin, and 13g of maleic rosin into the reaction vessel, heat to 117°C and stir until the rosin is completely dissolved in the solvent; cool down to 77°C, and add salicylic acid 4g, 24 acid 3g, triethanolamine 2g, benzotriazole 2.5g, stir well until mixed; cool to 22°C, add polyoxyethylene glyceryl ether 6.5g, hydrogenated castor oil 5g, stir and vacuum until mixed Uniformly, use a three-roll mill to grind the solid particles in the uniformly m...

Embodiment 3

[0041] 1. Take 5g of polyamide resin, 11.7g of ethanol, and 0.17g of hydroxyethyl cellulose into the autoclave, heat to 150~170°C while stirring continuously until the polyamide resin is completely dissolved; continue to stir and heat at 2°C Cool down to 70°C at a speed of / min, stop stirring and cool down to room temperature, take out the materials in the autoclave, separate the powder and solvent, and obtain 5g of pure polyamide resin nanoparticles after drying;

[0042]2. Add 28g of triethylene glycol monobutyl ether, 30g of perhydrorosin, 13g of disproportionated rosin, and 5g of maleic rosin into the reaction vessel, heat to 119°C and stir until the rosin is completely dissolved in the solvent; cool down to 79°C, add 7g of 24 acid, 2g of diethanolamine, 3.5g of benzotriazole, fully stirred until mixed evenly; cooled to 22°C, added 6.5g of polyoxyethylene glyceryl ether, 5g of polyamide resin, stirred and vacuumed until mixed evenly, Grinding the solid particles in the hom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com