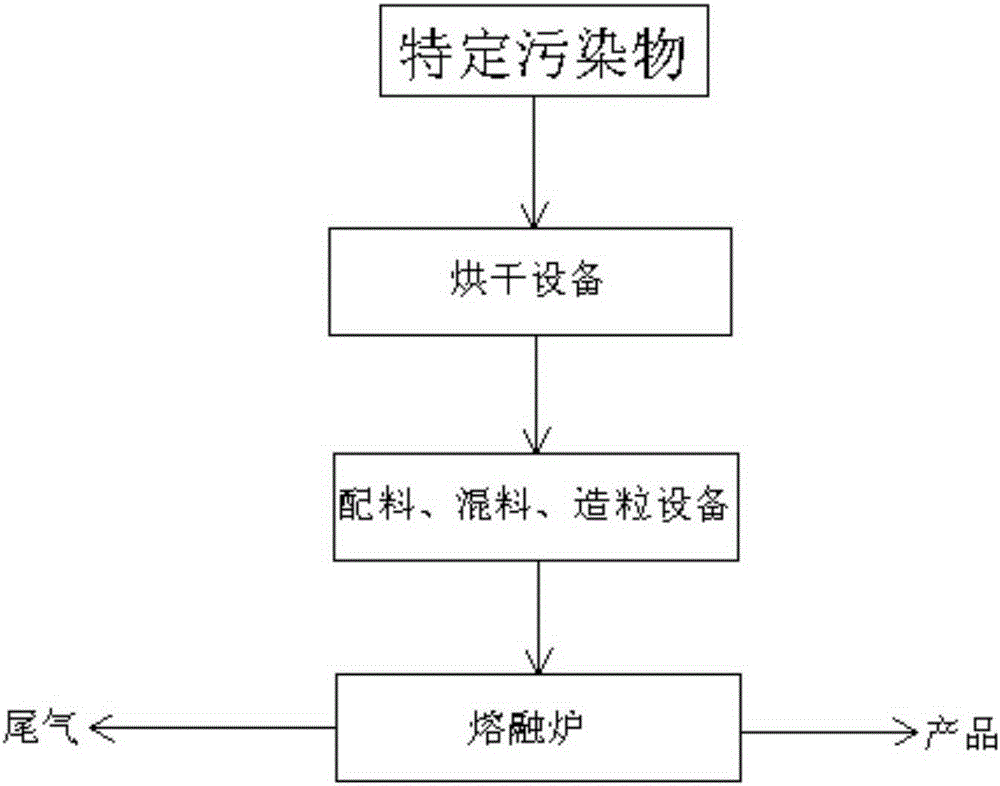

Method for treating specific pollutants through high-temperature melting technology

A technology of technical treatment and high-temperature melting, applied in chemical instruments and methods, removal of solid waste, improvement of process efficiency, etc., can solve the problems of high investment cost and operating cost, immature process technology, etc. The effect of solving heavy metal pollution and thorough resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

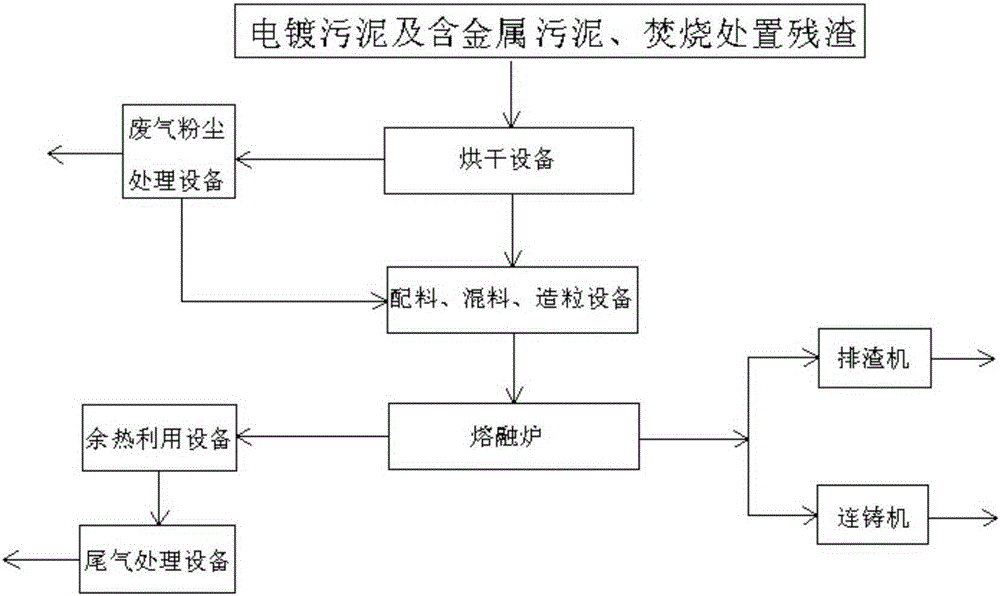

[0110] 1. A method of treating specific pollutants using high-temperature melting technology

[0111] Step 1: Pretreatment: The specific pollutants include electroplating sludge and metal-containing sludge, and incineration disposal residues. The water content of the electroplating sludge and metal-containing sludge is 80wt%. First, the electroplating sludge and metal-containing sludge The sludge is subjected to primary pretreatment to make its water content 35wt%, and then the electroplating sludge, metal-containing sludge, and incineration disposal residue are subjected to secondary pretreatment to make its water content below 10wt% to obtain specific pollutants Dry materials, specifically: the electroplating sludge and metal-containing sludge are sent to the paddle dryer, and the hollow paddle and the shell with a hollow interlayer have the characteristics of extremely high heat transfer area and material volume ratio. The medium (mainly steam) enters the hollow shaft throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com