Root paint relieving tablet and preparation method thereof

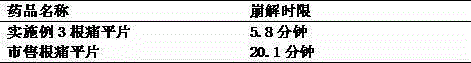

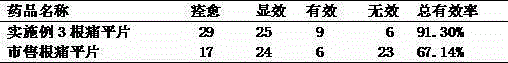

A technology of kudzu root and blocking collaterals, applied in the field of Gentongping tablet and its preparation, can solve the problems of slow disintegration, unsatisfactory curative effect, low curative effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 75.2g of schisandra, 18.8g of polygala, 188g of Andrographis paniculata, 47g of kudzu root, 50g of peach kernel, 56.4g of safflower, 47g of frankincense, 50g of myrrh, 150.4g of Dipsacus, 75g of dog spine (hot), 75.2g of Shenjincao, and grind them into 60-mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 19Mpa, extraction temperature 16°C, separator pressure 12Mpa, separator temperature 36°C, separation time 1.9 hours, carbon dioxide flow rate 25L per hour, to obtain the extract; The solution was dried under reduced pressure at 62°C to obtain a dry cream; take the dry cream and add 80 g of citric acid, and use a high-energy nano-impact mill to pulverize it into a mixed dry cream powder with a particle size of 200-300 nm; take the mixed dry cream powder, 35 g of microcrystalline cellulose, Hypromellose 35g, croscarmellose sodium 35g, magnesium aluminum silicate 15g, sodium chloride 5g, mannitol 4g, maltodextrin 4g, mix well...

specific Embodiment 2

[0035] Take 75.2g of schisandra, 18.8g of polygala, 188g of Andrographis paniculata, 47g of kudzu root, 50g of peach kernel, 56.4g of safflower, 47g of frankincense, 50g of myrrh, 150.4g of Dipsacus, 75g of dog spine (hot), 75.2g of Shenjincao, and grind them into 60 mesh coarse powder, extracted by supercritical carbon dioxide extraction, extraction pressure 39Mpa, extraction temperature 44°C, separator pressure 19Mpa, separator temperature 60°C, separation time 3.5 hours, carbon dioxide flow rate 33L per hour, to obtain the extract; The solution was dried under reduced pressure at 80°C to obtain a dry cream; take the dry cream and add 120g of citric acid, and use a high-energy nano-impact mill to pulverize it into a mixed dry cream powder with a particle size of 200-300nm; take the mixed dry cream powder, 45g of microcrystalline cellulose, Hypromellose 45g, croscarmellose sodium 45g, magnesium aluminum silicate 25g, sodium chloride 15g, mannitol 6g, maltodextrin 6g, mix well,...

Embodiment 3

[0037] Take 75.2g of schisandra, 18.8g of polygala, 188g of Andrographis paniculata, 47g of kudzu root, 50g of peach kernel, 56.4g of safflower, 47g of frankincense, 50g of myrrh, 150.4g of Dipsacus, 75g of dog spine (hot), 75.2g of Shenjincao, and grind them into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 29Mpa, extraction temperature 30°C, separator pressure 16Mpa, separator temperature 48°C, separation time 2.7 hours, carbon dioxide flow rate 29L per hour, to obtain the extract; The solution was dried under reduced pressure at 71°C to obtain a dry cream; take the dry cream and add 100 g of citric acid, and use a high-energy nano-impact mill to pulverize it into a mixed dry cream powder with a particle size of 200-300 nm; take the mixed dry cream powder, 40 g of microcrystalline cellulose, Hypromellose 40g, croscarmellose sodium 40g, magnesium aluminum silicate 20g, sodium chloride 10g, mannitol 5g, maltodextrin 5g, mix we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com