Solar aquatic plant harvester

A technology of solar energy and harvester, which is applied in river water environment, aquatic plants salvage and lake fields, can solve the problems of inoperability, hard work, bulky and heavy ships, etc., and achieve the effect of high degree of automation and control of growth height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

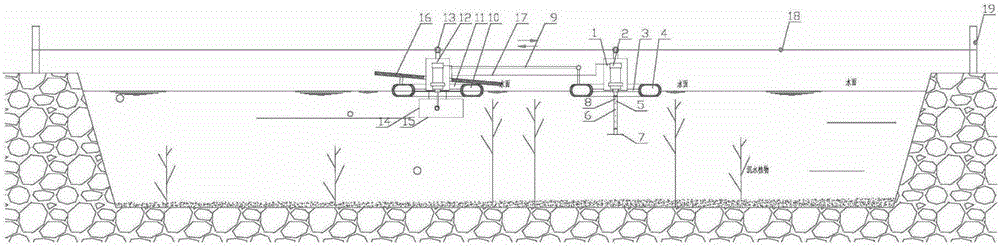

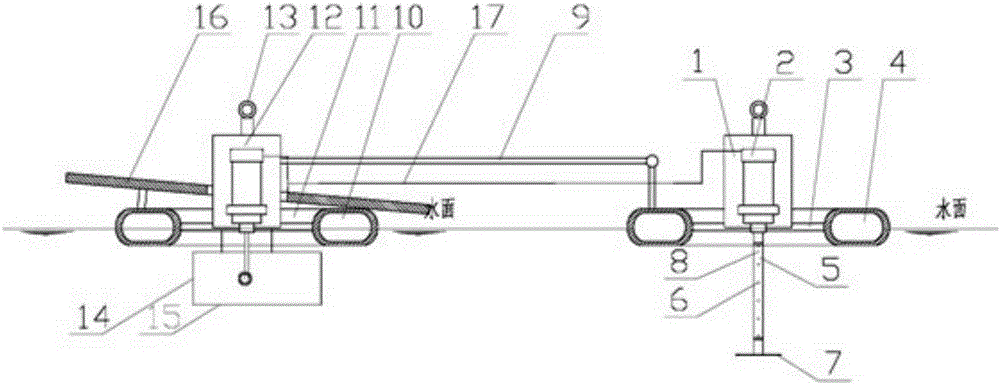

[0027] see figure 1 According to the invention, a solar water weed harvesting ship is composed of a solar power system, a water weed cutting device, and a water surface walking mechanism.

[0028] Wherein, the solar power system includes setting a double buoy hull 10 on the water surface, a stainless steel support 11 is arranged above, a solar battery panel 16 is built above the stainless steel support 11, a drive motor 12 is installed on the upper part of the middle position of the stainless steel support 11, and a horizontally placed one is installed below. Guide tube 14, propeller 15 is installed in the inside of the guide tube.

[0029] The aquatic grass cutting device is composed of a floating device, a DC motor, a height control device and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com