Display optical-diffusion film and display device using same

A technology of light diffusing film and display device, which can be used in identification devices, instruments, optics, etc., can solve problems such as narrowing of the viewing angle, and achieve the effect of reducing the lamination process, suppressing the generation of blur, and being economically beneficial.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0453] 1. Fabrication of light-diffusing film

[0454] (1) Synthesis of low refractive index polymerizable compound (B) component

[0455] In the container, put 2 moles of isophorone diisocyanate (IPDI) as the component (B1) and 1 mole of polypropylene glycol (PPG) as the component (B2) with a weight average molecular weight of 9200, and 2 moles as the component (B3) After 2 moles of 2-hydroxyethyl methacrylate (HEMA), they were reacted according to a conventional method to obtain polyether urethane methacrylate with a weight average molecular weight of 9900.

[0456] The weight-average molecular weights of polypropylene glycol and polyether urethane methacrylate are polystyrene-equivalent values measured by gel permeation chromatography (GPC) under the following conditions.

[0457] GPC measurement device: HLC-8020 manufactured by Tosoh Corporation

[0458] GPC column: Manufactured by Tosoh Corporation (below, listed in order of passage)

[0459] TSK guard column (guardc...

Embodiment 2

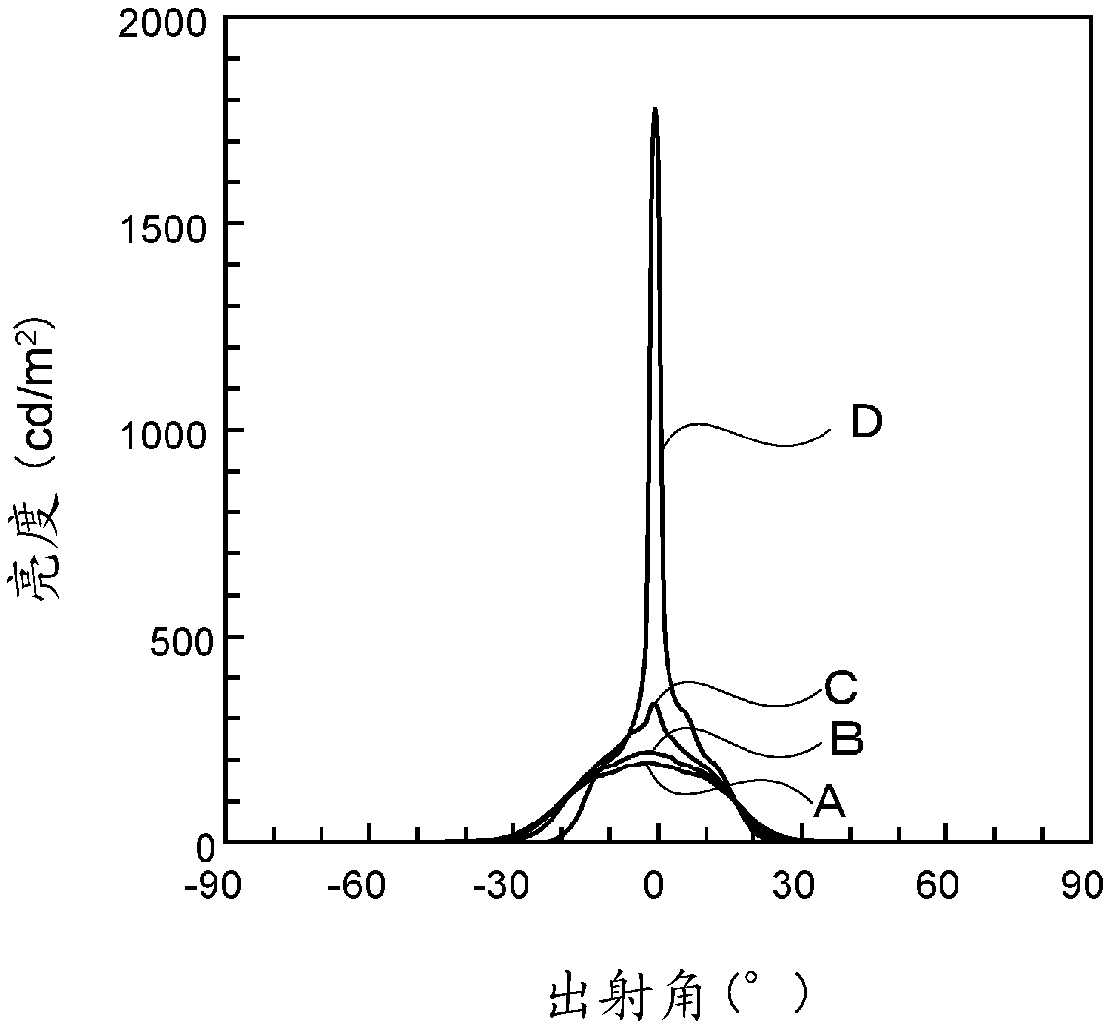

[0511] In Example 2, when coating the composition for light-diffusion films, except having changed the film thickness of the coating layer into 170 micrometers, it manufactured and evaluated the light-diffusion film similarly to Example 1. The internal structure in the obtained light-diffusing film was the same as in Example 1. Figure 4 (a) The column structure of the deformed column shown. In addition, the film thickness was 170 μm, and the measured haze value was 94%. Other obtained results are shown in Figures 16-17 as well as Figure 14 .

[0512] here, Figure 16 It is a conoscopic image when light is incident on the light-diffusing film of Example 2 so that an incident angle (theta)1=0 degrees using a conoscopic lens.

[0513] From the above-mentioned conoscopic image, it can be seen that uniform light that suppresses the linear propagation of the incident light and transmits it is diffused and emitted to the front of the film.

[0514] in addition, Figure 17 I...

Embodiment 3

[0520] In Example 3, when applying the composition for light-diffusion films, except having changed the film thickness of the coating layer into 135 micrometers, it manufactured and evaluated the light-diffusion film similarly to Example 1. The internal structure in the obtained light-diffusing film was the same as in Example 1. Figure 4 (a) The column structure of the deformed column shown. In addition, the film thickness was 135 μm, and the measured haze value was 93%. Other obtained results are shown in Figures 18-19 as well as Figure 14 .

[0521] here, Figure 18 It is a conoscopic image when light is incident on the light-diffusing film of Example 3 so that an incident angle (theta)1=0 degree using a conoscopic lens.

[0522] From the above-mentioned conoscopic image, it can be seen that uniform light that suppresses the linear propagation of the incident light and transmits it is diffused and emitted to the front of the film.

[0523] in addition, Figure 19 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com