Multi-polar permanent-magnet motor pole core structure

A magnetic pole core and permanent magnet motor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of difficult distribution of permanent magnet magnetic poles and difficult realization of permanent magnet motor rotor structure, etc., to achieve the goal of promoting The effect of developing and reducing the size of the motor and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

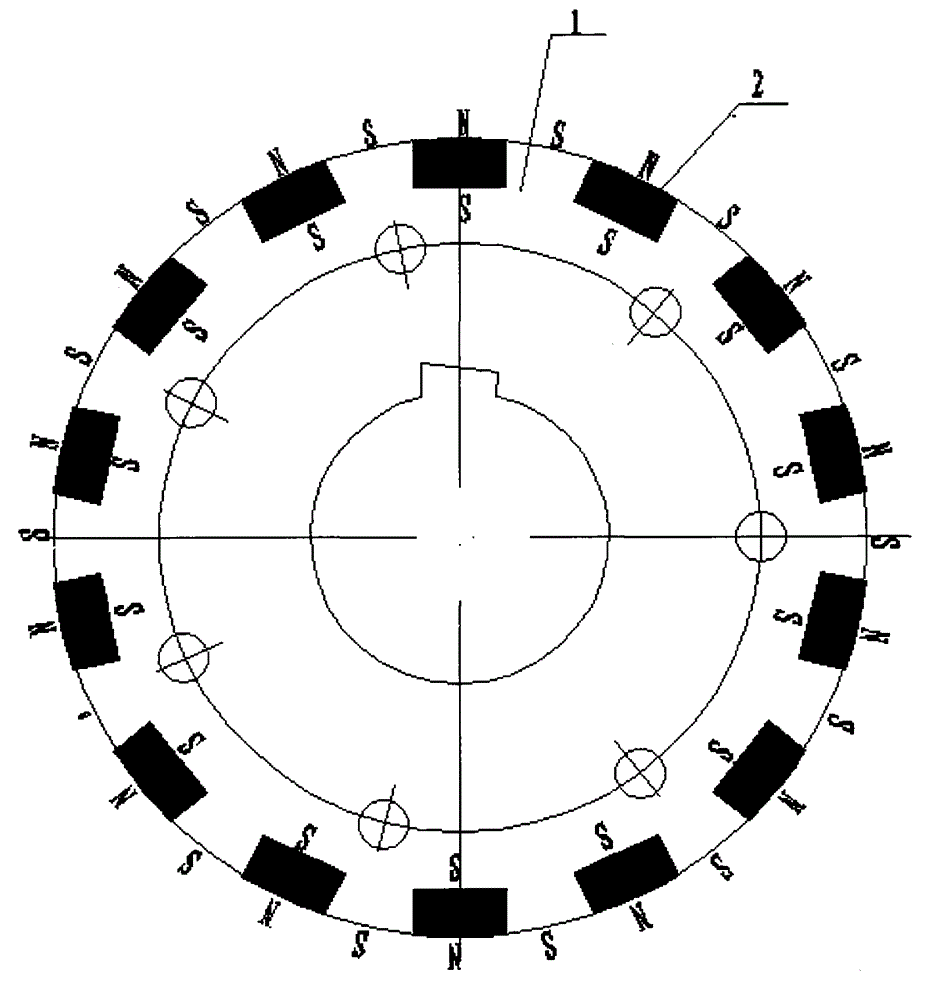

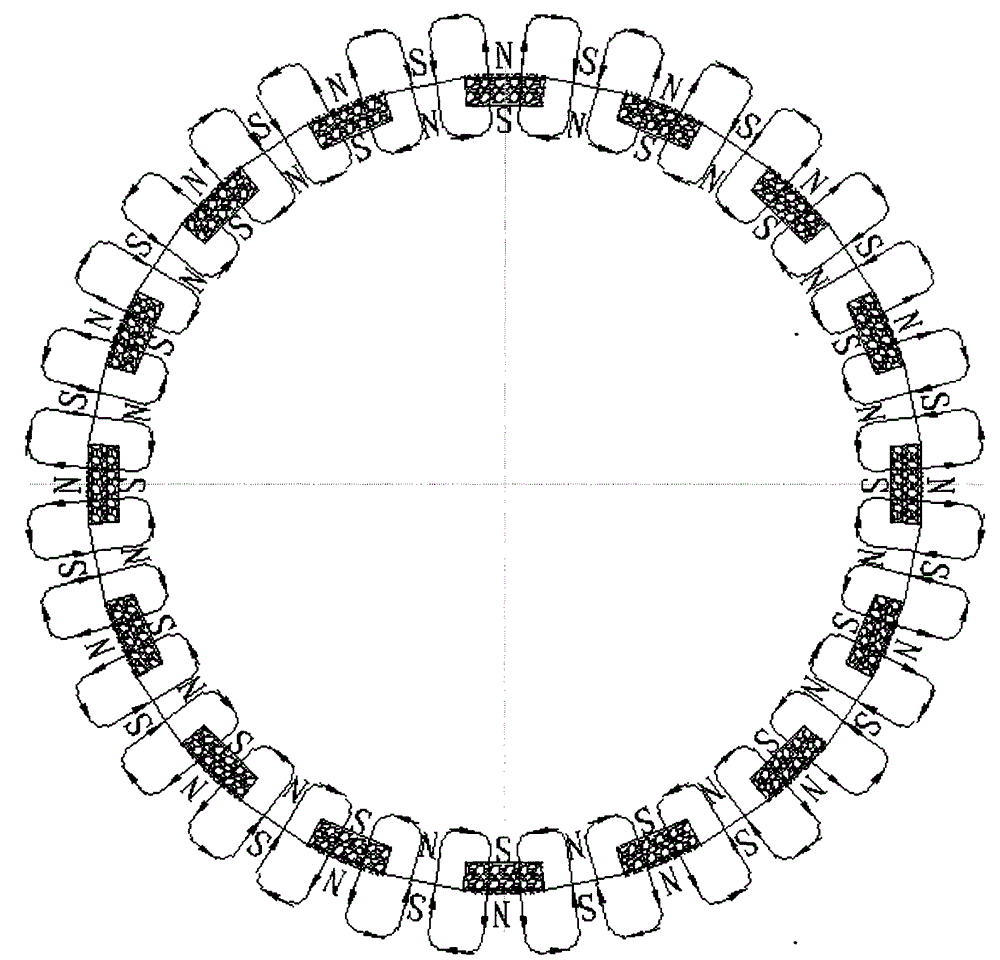

[0018] A kind of pole iron core structure of multi-pole permanent magnet motor described in the present invention, such as figure 1 As shown, magnetic steel slots are evenly opened on the magnetic pole core 1, the number of slots of the magnetic steel slots is the same as the number of pole pairs of the motor, and the arc length and width of the magnetic steel slots are basically the same as the arc length left between the two magnetic steel slots. The arc length of the magnetic steel slot is calculated by the following formula:

[0019] T=πD / P

[0020] Among them: T-the arc length width of the magnetic steel slot and the arc length distance between two magnetic steel slots, unit: mm

[0021] D-motor rotor outer diameter, unit: mm

[0022] P-number of motor poles

[0023] In actual production, according to the distance between the magnetic steel and the motor rotor surface, the arc length and width of the magnetic steel groove can be properly corrected.

[0024] The magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com