A Lightweight Leading Section Cable

A leading segment and cable technology, which is applied in the field of light leading segment cables, can solve the problems of increased operating depth, increased cable length, and impact on offshore operations, and achieves the effects of reducing operational difficulty, increasing tensile strength, and omitting pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

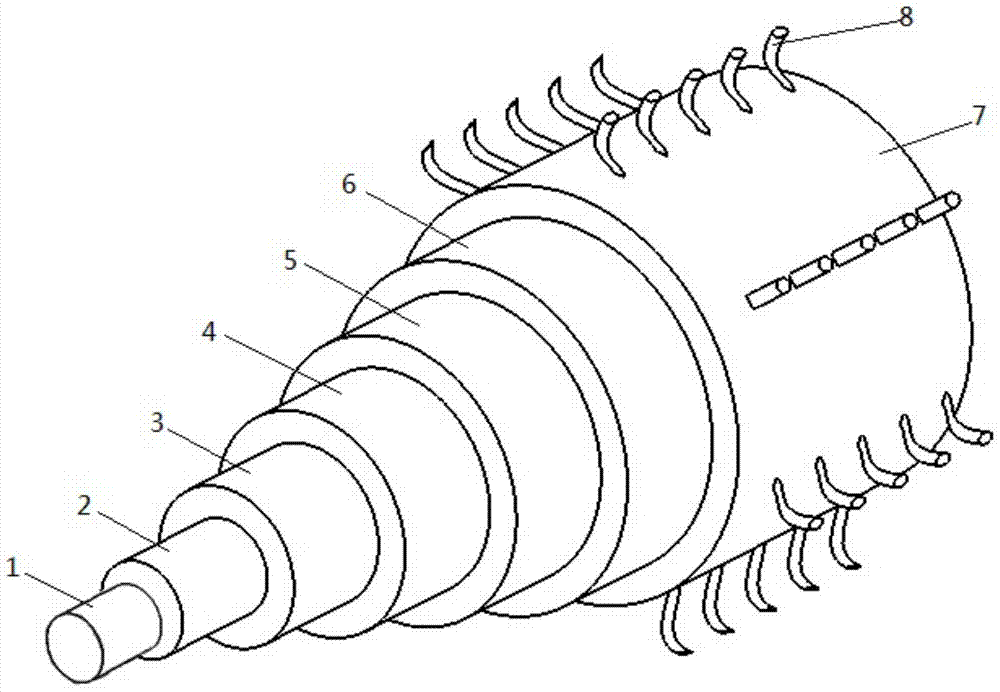

[0019] A light-duty leading cable, comprising a wire core 1, a shielding layer 2, a pressure-resistant layer 3, a waterproof layer 4, a tensile layer 5, a waterproof and wear-resistant layer 6, and a shock-absorbing layer 7, and the shielding layer 2 covers the wire core 1, The pressure-resistant layer 3 covers the shielding layer 2, the waterproof layer 4 covers the pressure-resistant layer 3, the tensile layer 5 covers the waterproof layer 4, the waterproof and wear-resistant layer 6 covers the tensile layer 5, and the shock-absorbing layer 7 covers the waterproof and durable Grinding layer 6.

[0020] The wire core 1 is a metal wire. Also, there is an optical fiber in the core 1 . The shielding layer 2 is wrapped with aluminum foil.

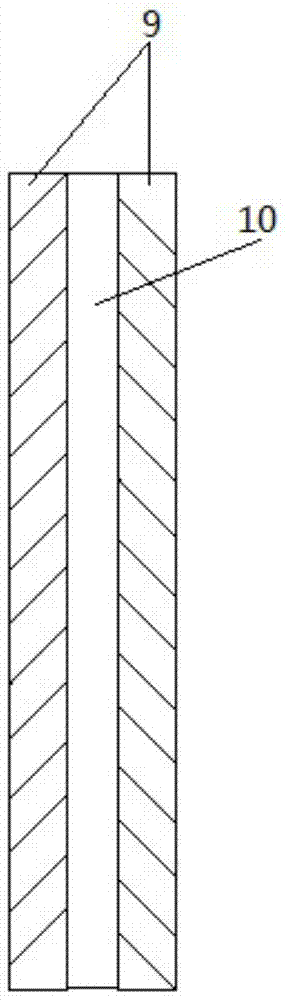

[0021] Such as figure 2 The tensile layer 5 includes composite wire layers 9 and glued layers 10 , the composite wire layers 9 and the glued layers 10 are arranged alternately, and the composite wire layers 9 are arranged around a common c...

Embodiment 2

[0025] A light-duty leading cable, comprising a wire core 1, a shielding layer 2, a pressure-resistant layer 3, a waterproof layer 4, a tensile layer 5, a waterproof and wear-resistant layer 6, and a shock-absorbing layer 7, and the shielding layer 2 covers the wire core 1, The pressure-resistant layer 3 covers the shielding layer 2, the waterproof layer 4 covers the pressure-resistant layer 3, the tensile layer 5 covers the waterproof layer 4, the waterproof and wear-resistant layer 6 covers the tensile layer 5, and the shock-absorbing layer 7 covers the waterproof and durable Grinding layer 6.

[0026] The core 1 is a signal wire. Also, the core includes three optical fibers. The shielding layer 2 is wound with copper foil.

[0027] Such as figure 2 The tensile layer 5 includes composite wire layers 9 and glued layers 10 , the composite wire layers 9 and the glued layers 10 are arranged alternately, and the composite wire layers 9 are arranged around a common center in t...

Embodiment 3

[0031] A light-duty leading cable, comprising a wire core 1, a shielding layer 2, a pressure-resistant layer 3, a waterproof layer 4, a tensile layer 5, a waterproof and wear-resistant layer 6, and a shock-absorbing layer 7, and the shielding layer 2 covers the wire core 1, The pressure-resistant layer 3 covers the shielding layer 2, the waterproof layer 4 covers the pressure-resistant layer 3, the tensile layer 5 covers the waterproof layer 4, the waterproof and wear-resistant layer 6 covers the tensile layer 5, and the shock-absorbing layer 7 covers the waterproof and durable Grinding layer 6.

[0032] The wire core 1 is a metal wire. Also, there is an optical fiber in the core 1 . The shielding layer 2 is wrapped with aluminum foil.

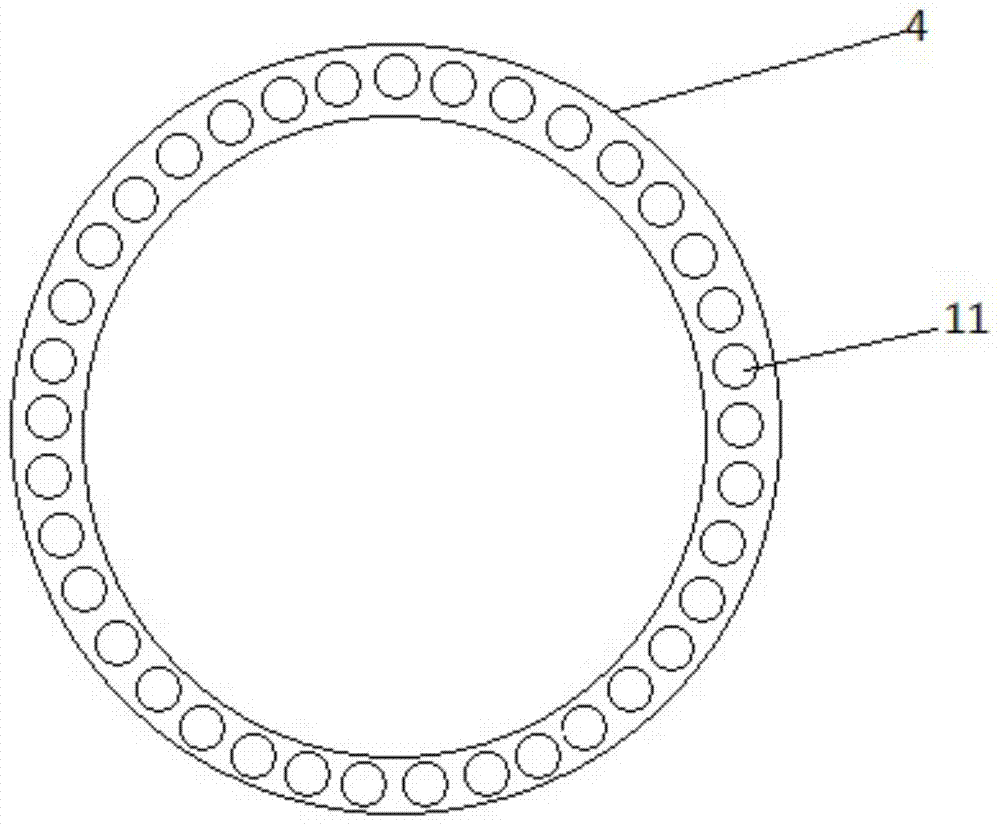

[0033] Such as image 3 The tensile layer 5 is surrounded by monofilament fibers, fiber bundles or fiber ropes 11 made of monofilament fibers or fiber bundles parallel to the cable axis.

[0034] The waterproof and wear-resistant layer 6 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com