Tensile test loading device and test method for unidirectional fiber reinforced composite materials perpendicular to the fiber direction

A technology of reinforced composite materials and unidirectional fibers, which is applied in the direction of measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure, which can solve the problems of uneven force on the clamping section, Problems such as the failure of the contact surface of the fixture to achieve the effect of ensuring accuracy, wide application range, and eliminating connection gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

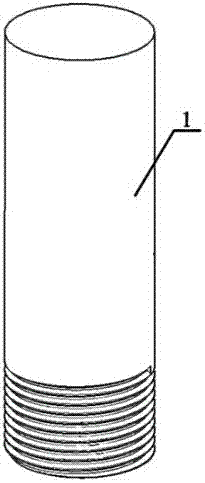

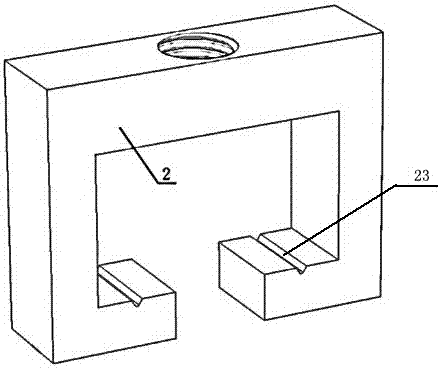

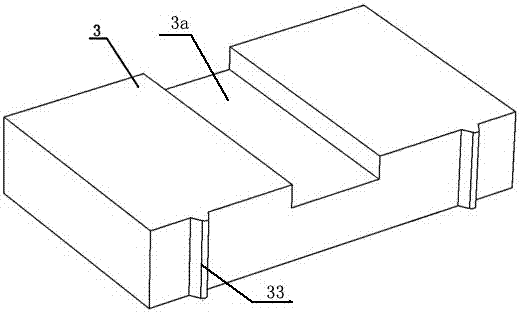

[0053] A tensile test loading device for unidirectional fiber-reinforced composite materials perpendicular to the fiber direction, including an upper clamping rod 1, a loading frame 2, a force transmission piece 3, a threaded connecting rod 5, a gap elimination nut 6, and a lower clamping rod 7; One end of the clamping rod 1 is provided with a right-handed thread, and the other end is a polished rod; one end of the lower clamping rod 7 is provided with a left-handed thread, and the other end is a polished rod; the loading frame 2 is two identical upper loading frame 21 and lower loading frame 22 , wherein the upper loading frame 21 is connected with the upper clamping rod 1, and the lower loading frame 22 is connected with the threaded connecting rod 5; A V-shaped positioning long groove with the same thickness as the loading frame 2 is symmetrically provided on the opening surface of the frame; the force transmission sheet 3 is provided with four identical pieces, which are re...

no. 2 example

[0068] Replace the unidirectional fiber-reinforced carbon / carbon composite strip-shaped tensile specimen in the first embodiment with a unidirectional fiber-reinforced resin-based composite material dog-bone tensile specimen, such as Figure 10 and Figure 11 shown. The parts not described are the same as the first embodiment.

no. 3 example

[0070] The unidirectional fiber-reinforced carbon / carbon composite strip tensile specimen in the first embodiment is replaced by the unidirectional fiber-reinforced ceramic matrix composite dovetail tensile specimen. Correspondingly, the groove 3a is as wide as the outside, Narrow dovetail trough on the inside, such as Figure 12 to Figure 14 shown. The parts not described are the same as the first embodiment.

[0071] The third embodiment improves the shape of the clamping part of the sample and the shape of the force transmission piece 3, so that the contact area between the sample and the force transmission piece 3 is larger. Wide and narrow inside, the sample is more difficult to come out, and the connection is firm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com