A high-precision vacuum dynamic control system for vacuum nitriding

A dynamic control, high-precision technology, applied in solid-state diffusion coating, metal material coating process, coating, etc., can solve the problem of large fluctuation of atmospheric pressure, affecting the uniformity and stability of nitrogen potential atmosphere, and quality indicators of difficult-to-handle parts and other problems to achieve the effect of reducing pressure fluctuation and ensuring quality stability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

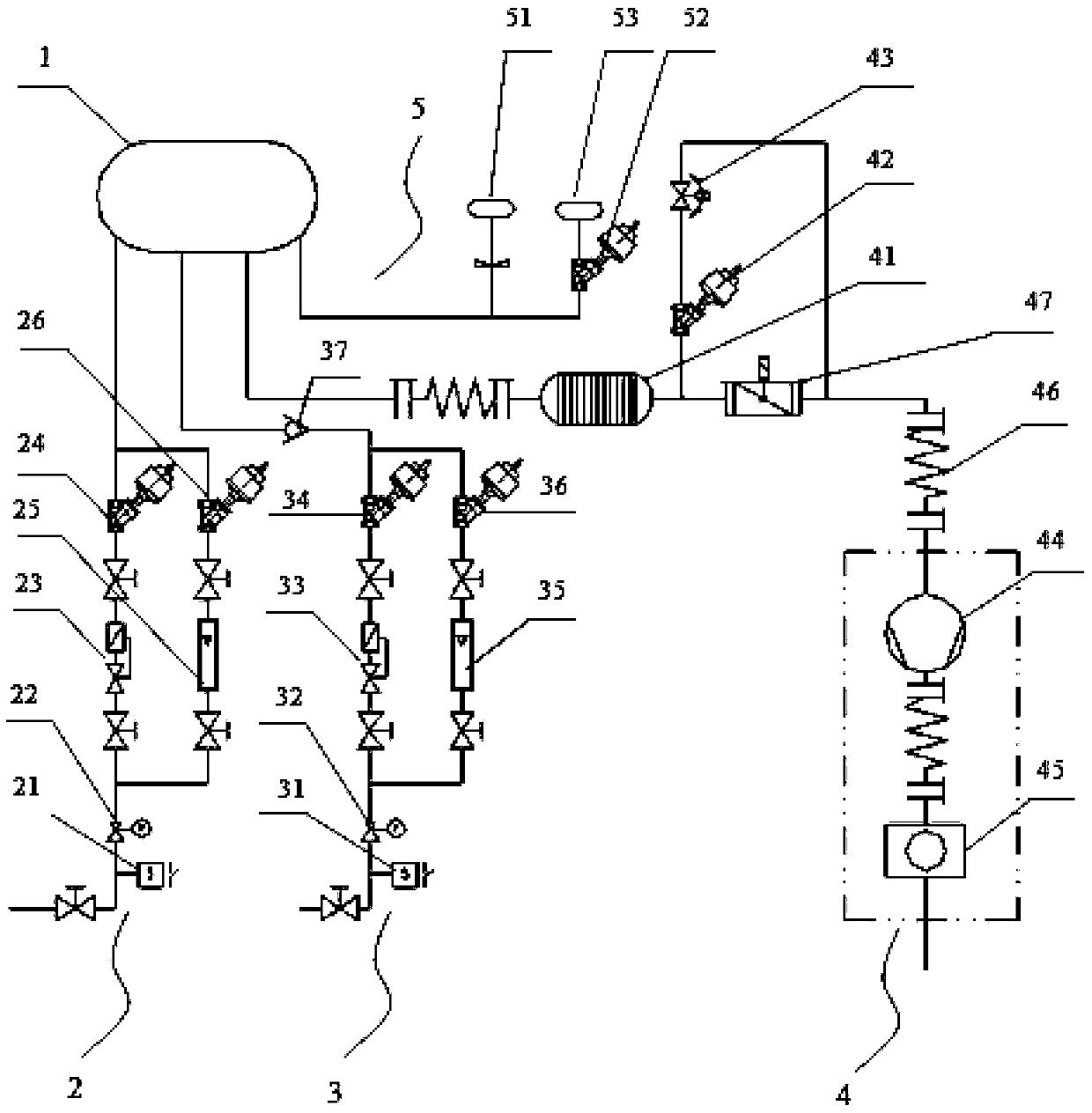

[0016] Such as figure 1 As shown, the high-precision vacuum dynamic control system for vacuum nitriding in this embodiment includes a vacuum furnace tank 1, an air intake system and an exhaust system.

[0017] The intake system includes a first intake duct 2 and a second intake duct 3 . The first air intake pipe 2 is provided with a first air intake control device, which includes a first pressure relay 21, a first pressure reducing valve 22, a first main road vacuum angle valve 24 and a first bypass vacuum valve. Angle valve 26; the second air intake pipe 3 is provided with a second air intake control device, the second air intake control device includes a second pressure relay 31, a second pressure reducing valve 32, a second main road vacuum angle valve 34 and a second air intake control device. Two bypass vacuum angle valves 36.

[0018] As a preferred embodiment, in this embodiment, a check valve 37 is further provided on the second air intake pipe 3 to prevent the gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com