Air supply and exhaust system and air supply and exhaust method for a sterilizing dryer

A dryer and air supply fan technology, applied in the direction of dryers, drying, packaging and sterilization, etc., can solve the problems of equipment pressure fluctuations, equipment air volume changes, equipment adjustment difficulties, etc., to achieve simple and convenient adjustment, reduce The effect of differential pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

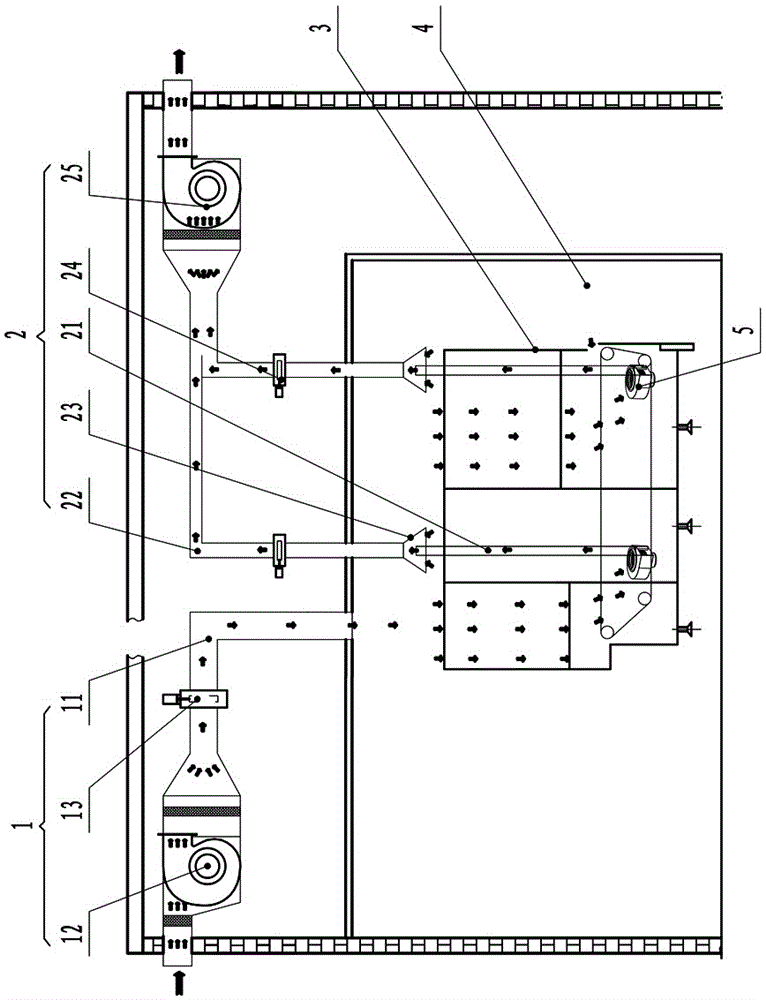

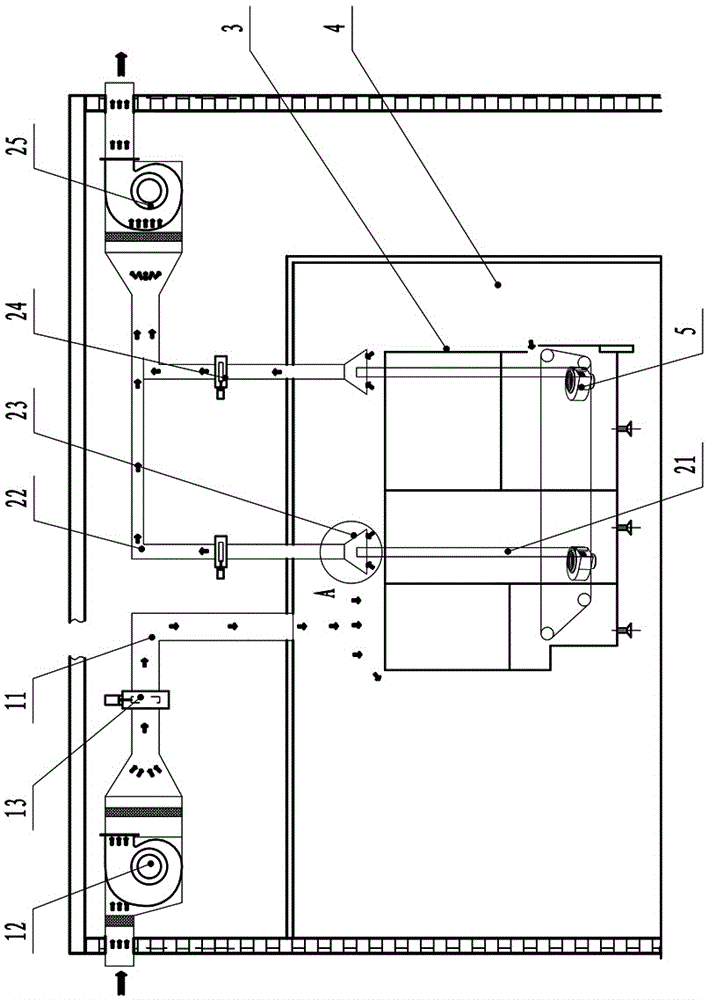

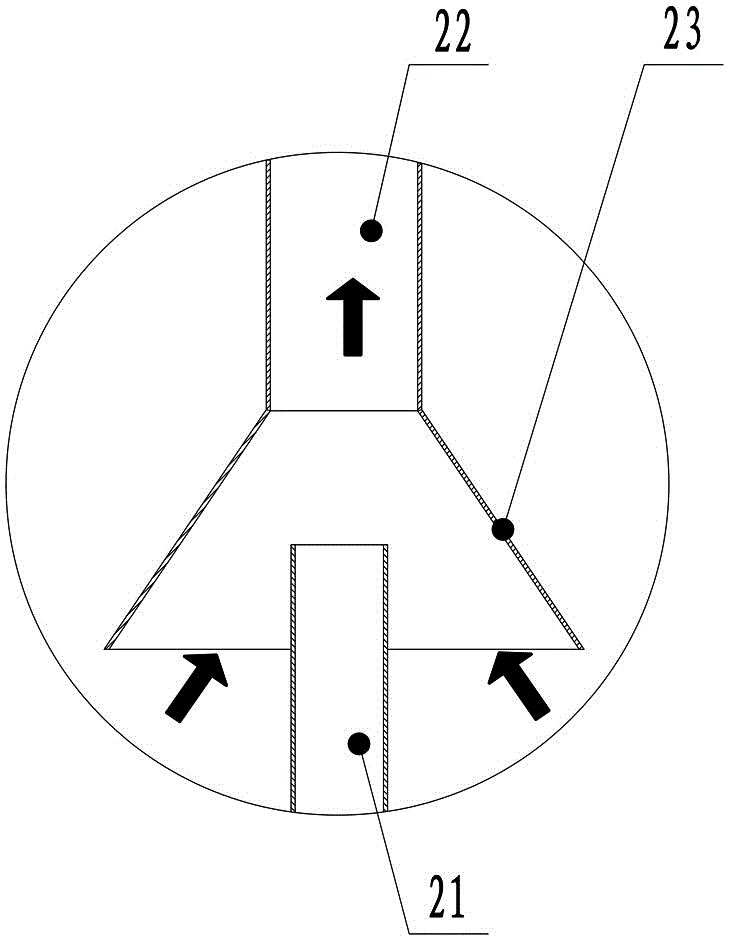

[0024] Such as Figure 1 to Figure 3 As shown, the air supply and exhaust system of the sterilization dryer in this embodiment includes an air supply assembly 1, an exhaust assembly 2, and a clean chamber 4. The sterilization dryer 3 is placed in the clean chamber 4, and the The air assembly 1 includes an air supply duct 11, the air supply duct 11 communicates with the clean chamber 4, the exhaust assembly 2 includes an exhaust duct 21 and an air introduction duct 22, the air introduction duct 22 communicates with the clean chamber 4, and the exhaust duct 21 The discharged gas directly enters the air-inducing duct 22 . Both the air supply duct 11 and the air induction duct 22 are in communication with the clean chamber 4. When the air volume of the air supply does not match the air volume required by the equipment, excess air can be sucked away through the air induction duct 22. Therefore, the air supply duct 11 is effectively avoided. When it is directly connected to the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com