Pressure limiting valve of aero-engine oil pump

A technology of aero-engine and pressure-limiting valve, which is applied in the direction of engine lubrication, engine components, lubricating oil control valve, etc., to achieve the effect of smooth adjustment and avoid adjustment difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

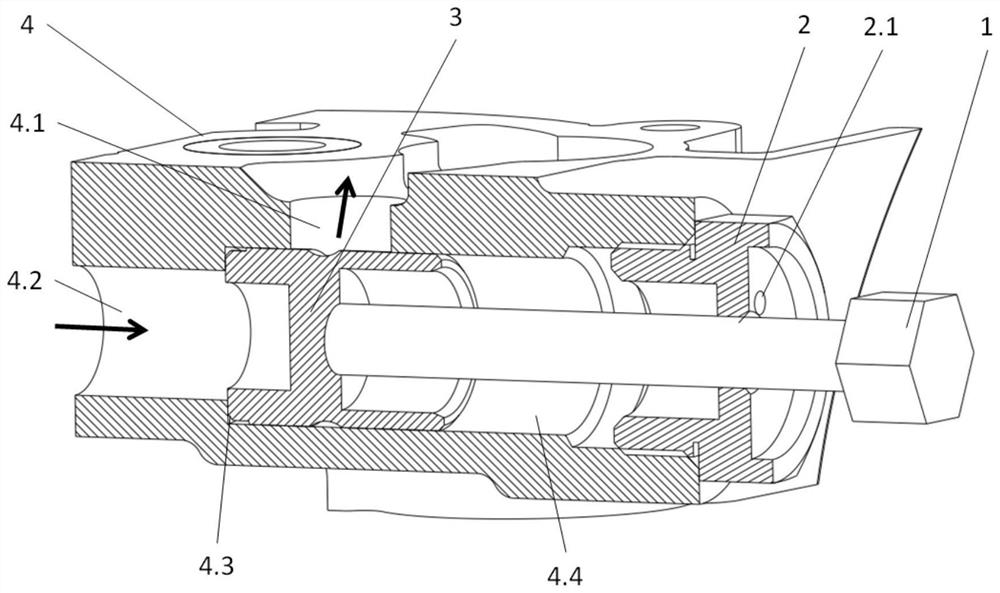

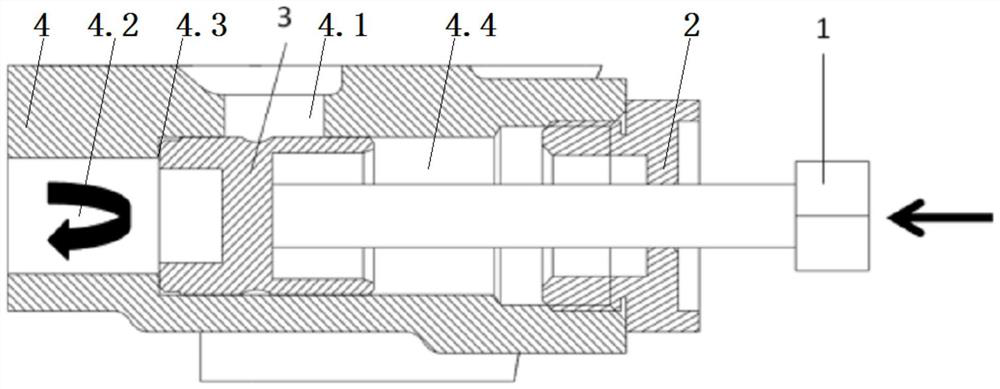

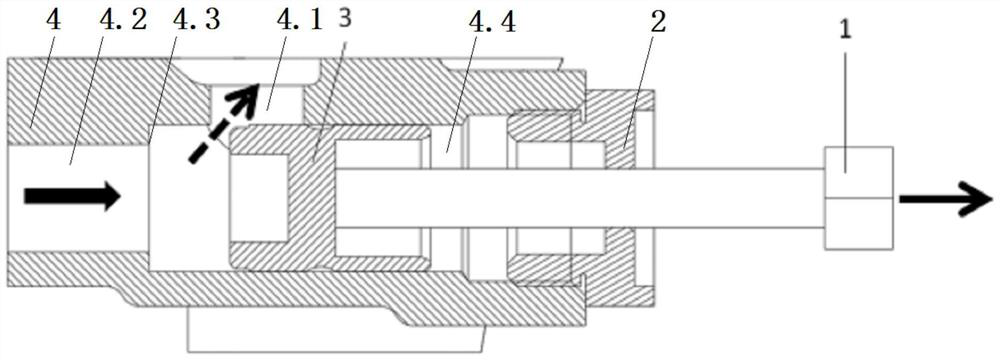

[0020] Example 1, as Figure 1-2 As shown, the present invention provides a technical solution: a pressure limiting valve for an aero-engine oil pump, comprising a rotatable screw 1, a screw plug 2, a displacement valve core 3 and an oil pump housing 4, the A screw plug 2 is provided inside, and the inside of the screw plug 2 is provided with an oil pressure adjustment mechanism for manually adjusting the pressure of the oil pump pressure limiting valve. The oil pressure adjustment mechanism includes a rotatable screw 1 and a displacement valve core 3. A rotatable screw 1 is provided through the fine thread, and the rotatable screw 1 and the screw plug 2 are in a threaded connection relationship. Displace the valve core 3, and the outer wall of the displacement valve core 3 matches the outer wall of the installation cavity 4.4 of the pressure limiting valve structure, and the outer wall of the displacement valve core 3 corresponds to the outer wall of the installation boss 4.3...

Embodiment 2

[0021] Example 2, as Figure 1-3 As shown, the present invention provides a technical solution: a pressure limiting valve for an aero-engine oil pump, comprising an oil pump housing 4 and an installation cavity 4.4 of the pressure limiting valve structure, and a middle position inside the oil pump housing 4 is opened The installation cavity 4.4 of the pressure-limiting valve structure, and the side of the installation cavity 4.4 of the pressure-limiting valve structure away from the screw plug 2 is provided with an oil pump high pressure feedback oil cavity 4.2, and the side wall of the screw plug 2 is provided with a pressure-limiting valve structure. Install the exhaust component of the air pressure in the cavity 4.4. The exhaust component includes an exhaust hole 2.1. The side wall of the screw plug 2 is provided with an exhaust hole 2.1 for connecting with the installation cavity 4.4 of the pressure limiting valve structure, and 2.2 is far away from One side of the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com