Quick switching method for screw oil pumps

A fast switching and screw technology, applied in the field of coal chemical industry, can solve problems such as motor overload, damage to equipment, and affect the safe operation of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

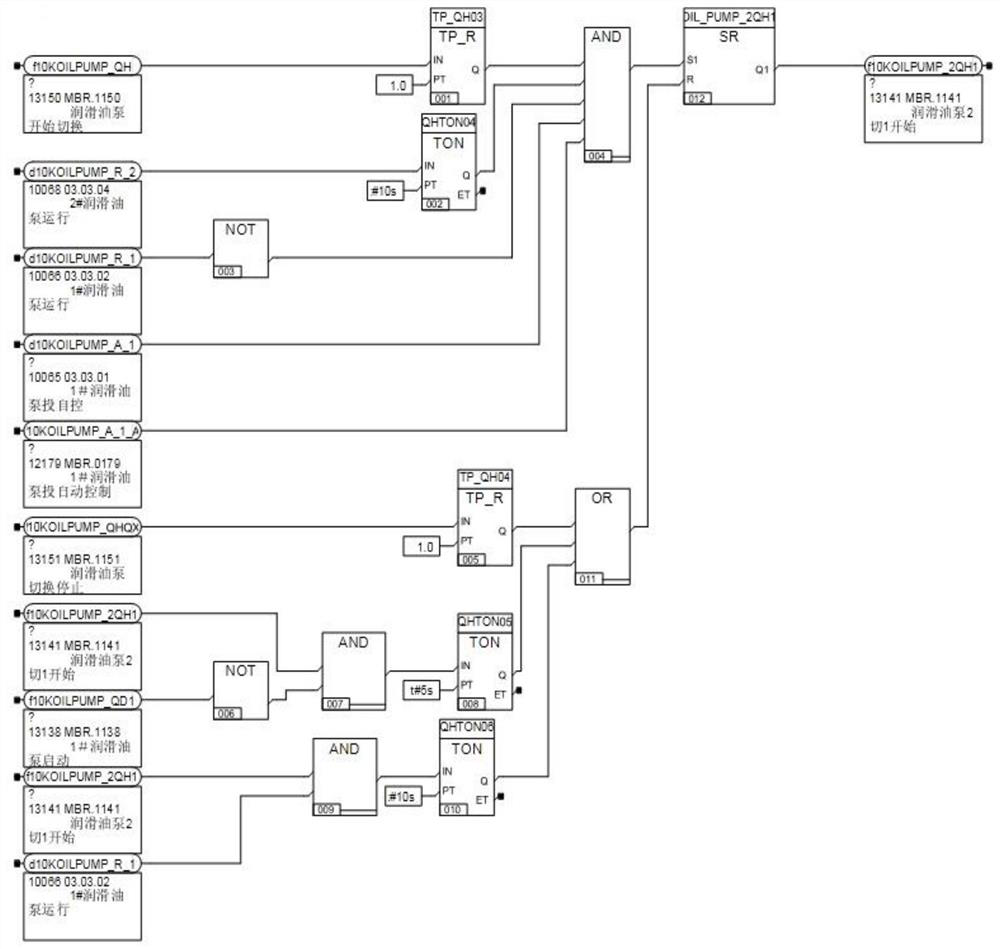

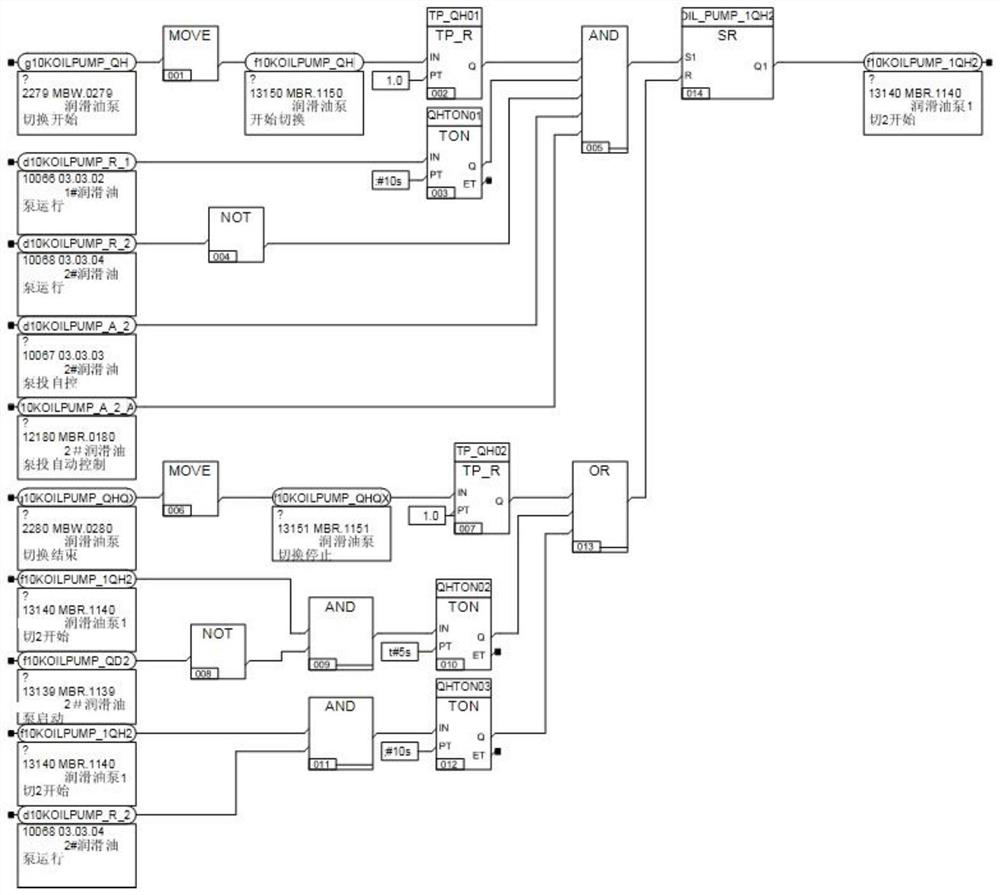

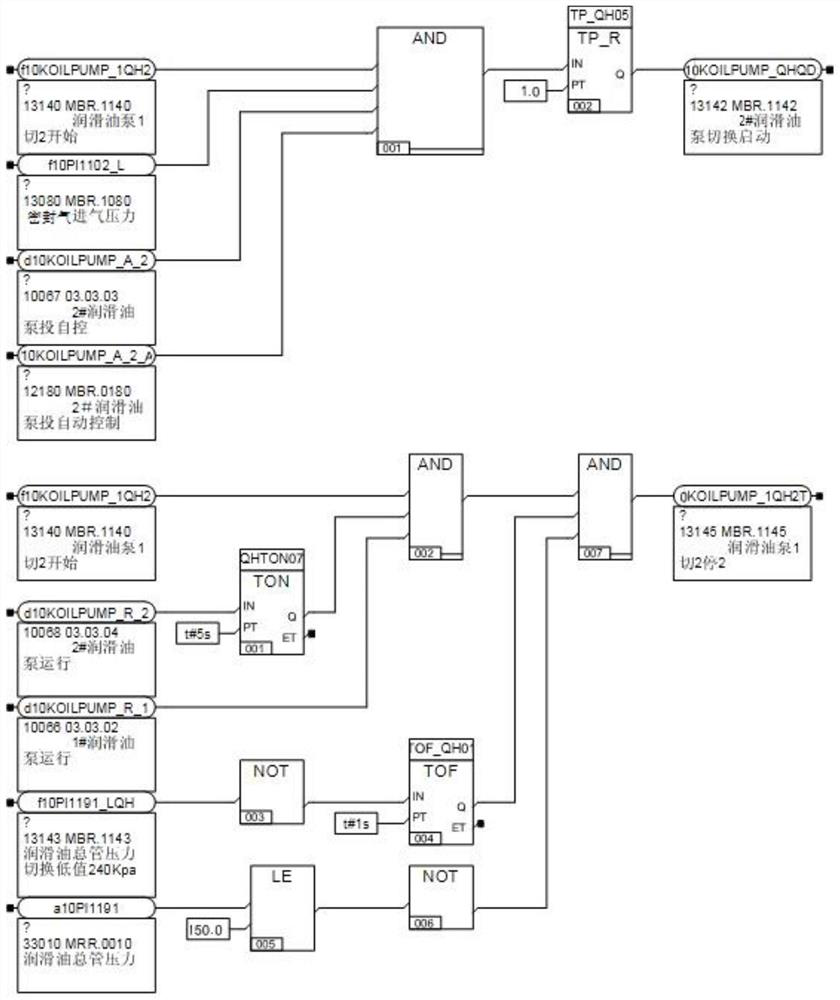

[0039] Increase the judgment, switching, start-stop logic of the screw lubricating oil pump, and add the switching start and switching end buttons and windows of the logical switching operation in the system screen.

[0040] During the operation of the lubricating oil system, both screw lubricating oil pumps are in the remote control mode. The operating pump is set as the main pump, the out-of-service pump is equipped with an auxiliary pump, the operating pump is kept under manual control, and the out-of-service pump is set to automatic control.

[0041] When performing the switching operation of the lubricating oil pump, after checking that the standby lubricating oil pump meets the switching conditions, click the switch to start on the operation screen, click Confirm to start in the pop-up window, and then execute the switching program, and click Cancel to exit the switching program

[0042] After the switching of the lubricating oil pump is completed, there is no need to cli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com