Glutinous rice adhesive being easy to blend and convenient to construct and used for wallpaper pasting, and preparation method thereof

A technology of glutinous rice glue and blending, applied in the direction of adhesive types, starch-derived adhesives, polymer adhesive additives, etc. Improve the low viscosity stability, improve the efficiency of construction and glue mixing, and have good high and low temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

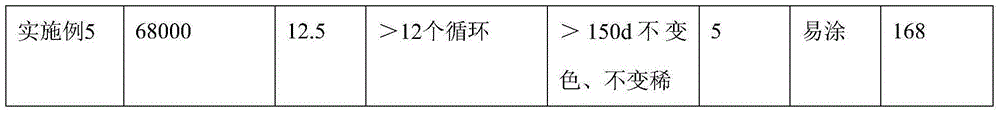

Examples

Embodiment 1

[0038] Deionized water: 650kg, glutinous rice flour: 50kg, waxy corn starch: 80kg, corn starch: 20kg, wheat starch: 30kg, potato starch: 50kg, tapioca starch: 20kg, borax: 0.15kg, cationic etherification agent: 18kg, chlorine Sodium acetate: 30kg, sodium carbonate: 20kg, sodium hydroxide: 30kg, polyethylene glycol 200: 2kg, glacial acetic acid: 5kg, ethanol: 10kg, benzoic acid: 2kg, calcium propionate: 2kg, sodium diacetate: 1kg, Natamycin: 0.3kg, sodium dehydroacetate: 0.4kg.

[0039] Preparation method: deionized water, glutinous rice flour (produced by Henan Huangguo Grain Industry Co., Ltd.), waxy corn starch (produced by Lihua Company in Qinhuangdao), cornstarch (produced by Zhucheng Xingmao Company), wheat starch (produced by Anhui Ante Company) production), potato starch (produced by Beidahuang Group Company), tapioca starch (produced by Guangxi Mingyang Company), polyethylene glycol (produced by Jiangsu Haian Petrochemical Plant), borax (produced by Yingkou Hongtai Bor...

Embodiment 2

[0042] Deionized water: 650kg, glutinous rice flour: 40kg, waxy corn starch: 90kg, corn starch: 25kg, wheat starch: 25kg, potato starch: 40kg, tapioca starch: 30kg, borax: 0.2kg, cationic etherification agent: 15kg, chlorine Acetic acid: 40kg, potassium hydroxide: 30kg, sodium phosphate: 25kg, polyethylene glycol 400: 2kg, glacial acetic acid: 5kg, ethanol: 10kg, benzoic acid: 1kg, potassium sorbate: 2kg, calcium propionate: 2kg, bis Sodium acetate: 1kg, natamycin: 0.3kg, sodium dehydroacetate: 0.4kg.

[0043]Preparation method: deionized water, glutinous rice flour (produced by Henan Huangguo Grain Industry Co., Ltd.), waxy corn starch (produced by Lihua Company in Qinhuangdao), cornstarch (produced by Zhucheng Xingmao Company), wheat starch (produced by Anhui Ante Company) production), potato starch (produced by Beidahuang Group Company), tapioca starch (produced by Guangxi Mingyang Company), polyethylene glycol (produced by Jiangsu Haian Petrochemical Plant), borax (produce...

Embodiment 3

[0046] Deionized water: 650kg, glutinous rice flour: 40kg, waxy corn starch: 90kg, corn starch: 25kg, wheat starch: 25kg, potato starch: 40kg, tapioca starch: 30kg, borax: 0.2kg, cationic etherification agent: 18kg, chlorine Acetic acid: 38kg, sodium carbonate: 30kg, sodium hydroxide: 25kg, polyethylene glycol 400: 2kg, glacial acetic acid: 5kg, ethanol: 10kg, benzoic acid: 1kg, potassium sorbate: 2kg, calcium propionate: 2kg, bis Sodium acetate: 1kg, natamycin: 0.3kg, sodium dehydroacetate: 0.4kg.

[0047] Preparation method: deionized water, glutinous rice flour (produced by Henan Huangguo Grain Industry Co., Ltd.), waxy corn starch (produced by Lihua Company in Qinhuangdao), cornstarch (produced by Zhucheng Xingmao Company), wheat starch (produced by Anhui Ante Company) production), potato starch (produced by Beidahuang Group Company), tapioca starch (produced by Guangxi Mingyang Company), polyethylene glycol (produced by Jiangsu Haian Petrochemical Plant), borax (produced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| 180°peel strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com