Highly wear-resistant bio-based polyamide composite material and preparation method thereof

A bio-based polyamide and composite material technology is applied in the field of modified polyamide composite materials and their preparation, which can solve the problems such as the inability to maintain the wear resistance of wear-resistant polyamide modified materials for a long time, and achieve good mechanical properties and relatively low cost. The effect of low and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the high wear-resistant bio-based polyamide composite material of the present invention comprises the following steps:

[0038] (1) Add polyamide resin, high molecular weight amino polysiloxane resin, dispersant and anti-aging agent into a high-speed mixer according to a certain proportion, and mix uniformly at room temperature to obtain a mixture;

[0039] (2) Using a twin-screw extruder to extrude the mixture obtained in step (1) to pelletize at 220-300° C., cool and dry to obtain a high wear-resistant bio-based polyamide composite material.

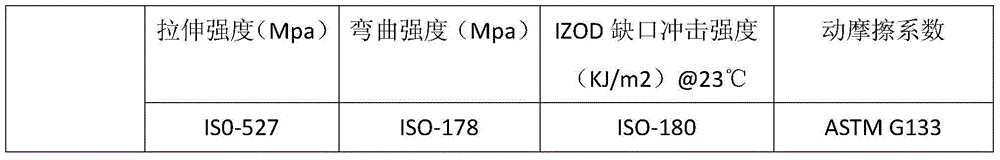

[0040] The following examples have adopted the following characterization methods to characterize the performance of the high wear-resistant bio-based polyamide composite:

[0041] 1. Tensile strength: measured according to ISO527-2 method.

[0042] 2. Bending strength: measured according to ISO178 method.

[0043] 3. Izod notched impact strength: measured according to ISO1791eA method.

[0044] 4. C...

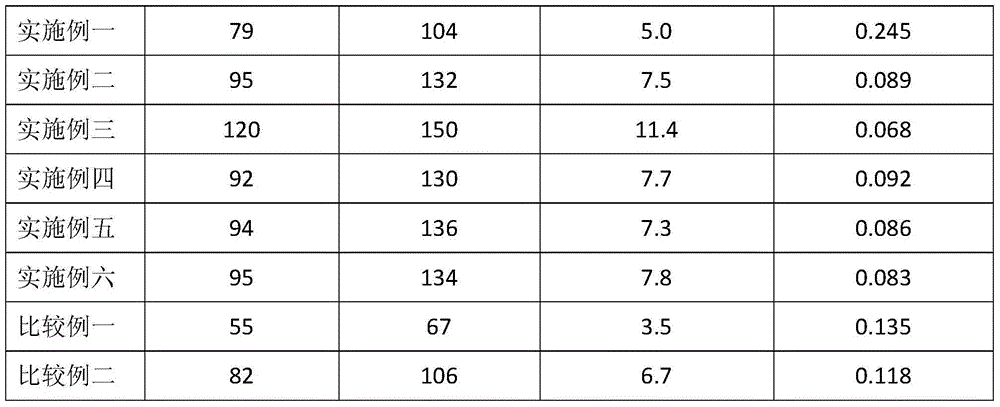

Embodiment 1

[0061] In this embodiment, the molecular weight of the aminopolysiloxane resin used is 1 million, and the viscosity number of PA56 is 2.8. The preparation method of the high wear-resistant bio-based polyamide composite material in this embodiment is as follows:

[0062] (1) The ratio shown in Table 1, the polyamide 56 (PA56) of 100 parts by weight, the dispersant EBS of 0.5 parts by weight and the antiaging agent HS-03 of 1.5 parts by weight are blended by a high-speed mixer, and The mixture obtained after blending was supplied to a ZSK 40 mm twin-screw extruder manufactured by Keya (set temperature: a temperature based on the melting point of polyamide resin about 30° C. higher, screw rotation speed 300 rpm) from the top feed port.

[0063] (2) Add 0.5 parts by weight of anti-wear agent aminopolysiloxane resin into the twin-screw extruder from the side feed port.

[0064] (3) Cool the molten kneaded product extruded from the outlet of the die in the form of strands, and pell...

Embodiment 2

[0067] In this embodiment, the molecular weight of the aminopolysiloxane resin used is 1 million, and the viscosity number of PA56 is 2.2. The preparation method of the high wear-resistant bio-based polyamide composite material in this embodiment is as follows:

[0068] (1) The ratio shown in Table 1, the polyamide 56 (PA56) of 100 parts by weight, the dispersant EBS of 0.5 parts by weight and the antiaging agent HS-03 of 1.5 parts by weight are blended by a high-speed mixer, and The mixture obtained after blending was supplied to a ZSK 40 mm twin-screw extruder manufactured by Keya (set temperature: a temperature based on the melting point of polyamide resin about 30° C. higher, screw rotation speed 300 rpm) from the top feed port.

[0069] (2) Add 12 parts by weight of anti-wear agent aminopolysiloxane resin into the twin-screw extruder from the side feed port.

[0070] (3) Cool the molten kneaded product extruded from the outlet of the die in the form of strands, and pelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com