Melt state sensing system and detection method in injection mold based on point electrodes

An injection mold and state sensing technology, which is applied in the melt state sensing system and its detection field in the injection mold based on point electrodes, can solve the problems of difficult installation of plate capacitors, low flexibility, and narrow applicability, so as to reduce the impact, High flexibility and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

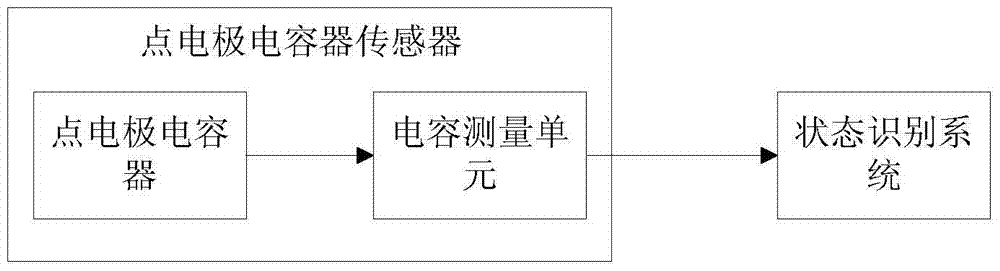

[0052] The point electrode-based melt state perception system in the injection mold of the present invention includes a state identification system and a point electrode capacitance sensor composed of a point electrode capacitor and a capacitance measuring unit. The two parts are introduced respectively below.

[0053] (1) Point electrode capacitive sensor

[0054] In order to meet the needs of online measurement of flat-shaped products (such as mobile phone casings), some people have designed and processed flat-type capacitive sensors, but flat-type capacitors cannot be installed in plastic product molds with complex cavity surface structures. Based on this requirement, the present invention designs a novel point electrode capacitor sensor to solve the online measurement problem of complex surface plastic products.

[0055] The point sensor of the present invention can not only play the role of a flat plate capacitive sensor in the form of an array, but also can be rationall...

no. 2 example

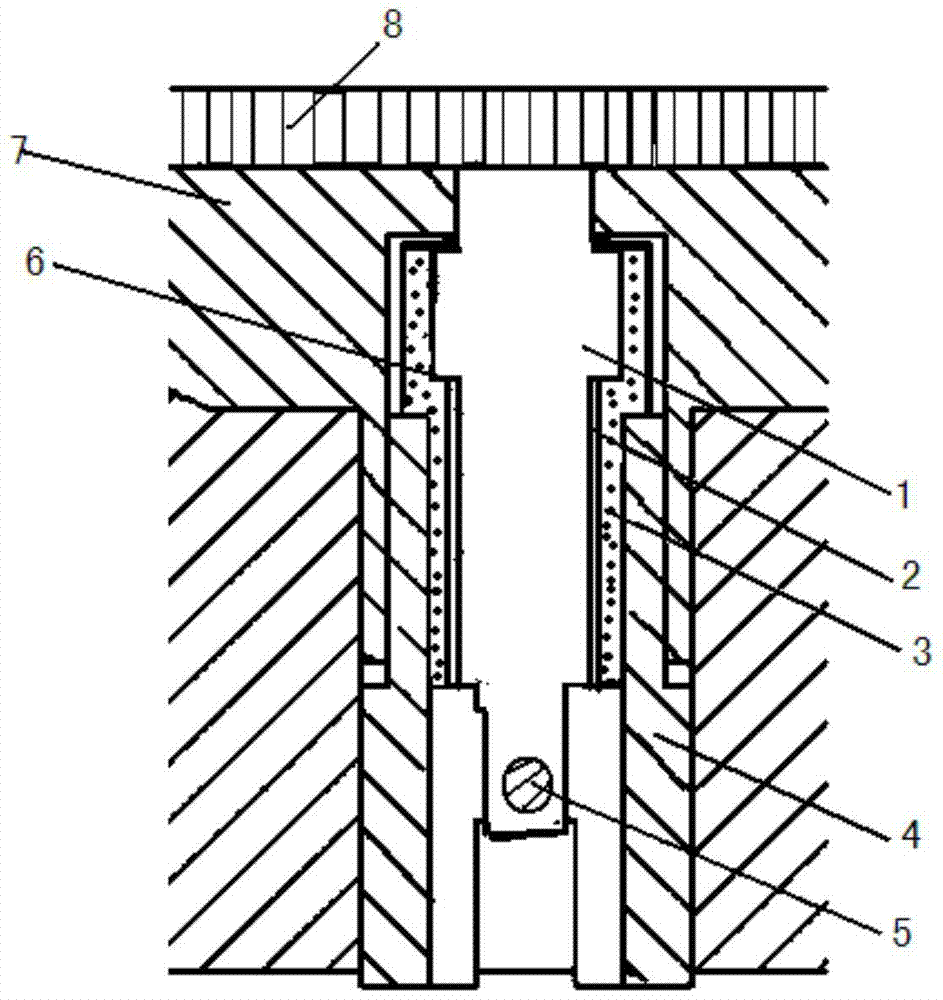

[0064] For the sake of reliability, the point electrode capacitive sensor of the present invention is divided into three parts, which are respectively point electrodes, nests and bolts. The design of the point electrode needs to consider its working environment. In the mold, the point electrode must not only bear the pressure from the plastic in the mold cavity, but also must ensure that its electrode plate does not enter the mold cavity, so as to avoid affecting the product quality. Therefore, the point electrode plate needs to be positioned in two directions. Such as figure 2 As shown, the positioning of the point electrode in the present invention is realized by the shaft shoulder, and the upper part of the shaft shoulder cooperates with the positioning hole of the mold to realize the positioning in the upward direction; Mold fits to achieve positioning in the downward direction.

[0065] The present invention designs the point electrode, the nest and the threaded bolt ...

no. 3 example

[0070] The realization process of the method for detecting the state of the melt in the injection mold based on the point electrodes of the present invention is as follows:

[0071] (1) Install the point electrode of the point electrode capacitive sensor at the key point of the injection molding process, and connect the point electrode capacitive sensor with the state recognition system through the capacitance measurement unit, wherein the key point of the injection molding process is located in the mold, and the point electrode It can be arranged at the key points of the injection molding process, such as the glue inlet, the final filling position, and the final cooling position;

[0072] (2) The state recognition system sets the sampling period and regularly collects the output voltage according to the sampling period;

[0073] (3) The state recognition system records the collected output voltage and collection time, and obtains the corresponding output voltage-time curve; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com