Steam curing device of slag unburned bricks

A technology of steam curing and non-burning bricks, which is applied in the field of brick maintenance equipment and steam curing equipment for slag non-burning bricks. It can solve problems such as cracking and falling off corners, faults and internal holes, and externally cooked and endogenous bricks, so as to save energy. , reduce steam consumption, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

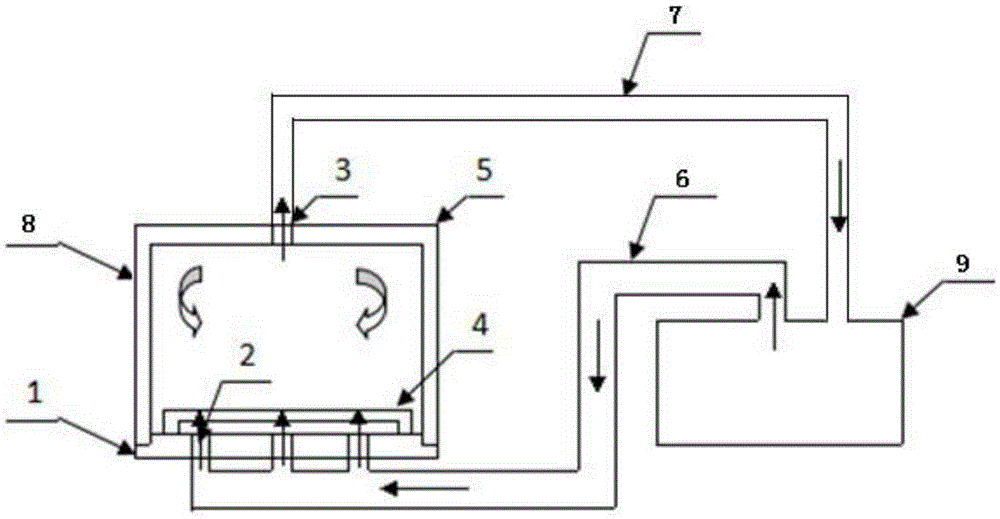

[0024] A steam curing equipment for slag-free bricks, including a steam curing reaction tank 8 and a steam output device 9, the steam curing reaction tank 8 includes a base 1, a brick bracket 4, a cover body 5, an air inlet pipe 6 and an exhaust pipe 7. The adobe bracket 4 is placed on the base 1, and the base 1 is provided with three air inlet holes 2, the air inlet holes 2 are connected to the air inlet pipe 6, and the cover body 5 covers the base 1 , the cover body 5 is provided with an exhaust port, the exhaust port 3 is connected to the exhaust pipe 7, and the air inlet pipe 6 and the exhaust pipe 7 are respectively connected to the steam output device 9 to realize the recycling of steam . .

Embodiment 2

[0026] A steam curing equipment for slag-free bricks, comprising a steam curing reaction tank 8 and a constant temperature water bath 9, the steam curing reaction tank 8 includes a base 1, a brick bracket 4, a cover body 5, an air inlet pipe 6 and an exhaust pipe 7. The brick adobe support 4 is a porous brick adobe support, which is placed on the base 1, and the base 1 is provided with four air inlet holes 2, the diameter of the air inlet holes 2 is 120-180 mm, and the hole spacing is 300-500 mm. The air inlet hole 2 is connected to the air inlet pipe 6; the cover body 5 covers the base 1, and the cover body 5 is covered with aluminum foil composite glass fiber cloth or ceramic fiber cloth, and the cover body is provided with row Air port 3, the caliber of described exhaust port 3 is 250~350mm, described exhaust port 3 is connected with exhaust pipe 7, and described air inlet pipe 6 and exhaust pipe 7 are connected with constant temperature water bath 9 respectively, realizes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com