A device for cooling circulating water of blast furnace by using low-temperature residual heat of sintering

A technology of low-temperature waste heat and circulating water, applied in energy-saving heating/cooling, blast furnaces, blast furnace details, etc., can solve problems such as investment, energy consumption, and operating costs that cannot be the most economical, water temperature cannot be effectively guaranteed, and cooling effects are not ideal. Reasonable and effective cooling control, improved cooling effect, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention are described below through specific embodiments. On the premise that there is no conflict with the purpose of the present invention, the embodiments mentioned below and the technical features in the embodiments can be combined with each other.

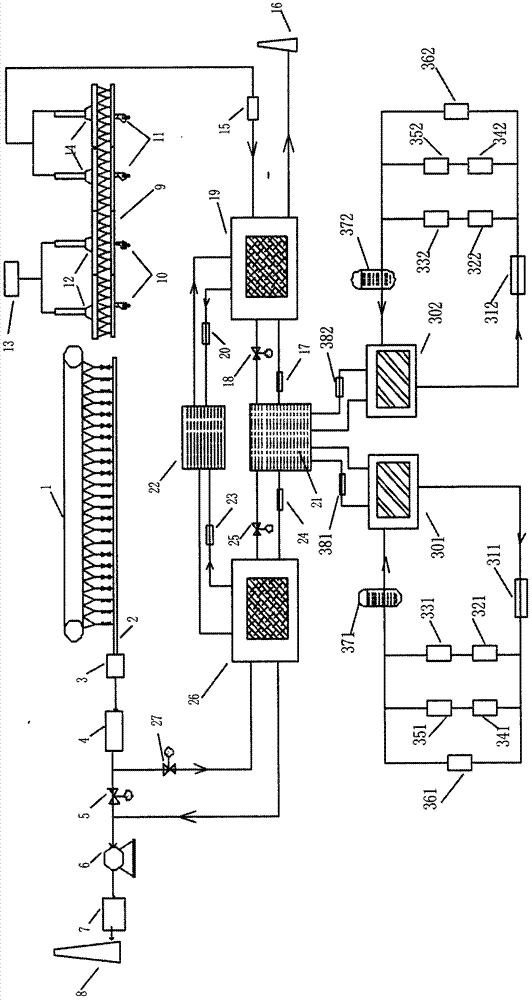

[0035] Such as figure 1 As shown, the marks in the figure are: 1-sintering machine, 2-large flue of sintering machine, 3-two-stage multi-pipe dust removal device, 4-bag dust removal device, 5-valve 1, 6-fan, 7-desulfurization and denitrification Device, 8-chimney 1, 9-circular cooler, 10-1, 2-stage blower, 11-3, 4-stage blower, 12-1, 2-stage chimney, 13-waste heat power generation device, 14-3, 4-stage Chimney, 15-dust removal device, 16-chimney 2, 17-water pump 1, 18-valve 4, 19-the first lithium bromide cooler, 20-water pump 2, 21-collecting tank, 22-circulating water tank, 23-water pump 3 , 24-water pump 4, 25-valve 3, 26-second lithium bromide cooler, 27-valve 2,

[0036] N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com