Copolymer using nano calcium phosphate coated polymethyl methacrylate as substrate and coating method thereof

A technology of polymethyl methacrylate and nano-calcium phosphate, which can be used in coatings, pharmaceutical formulations, dental preparations, etc., and can solve problems such as inability to bond to bones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

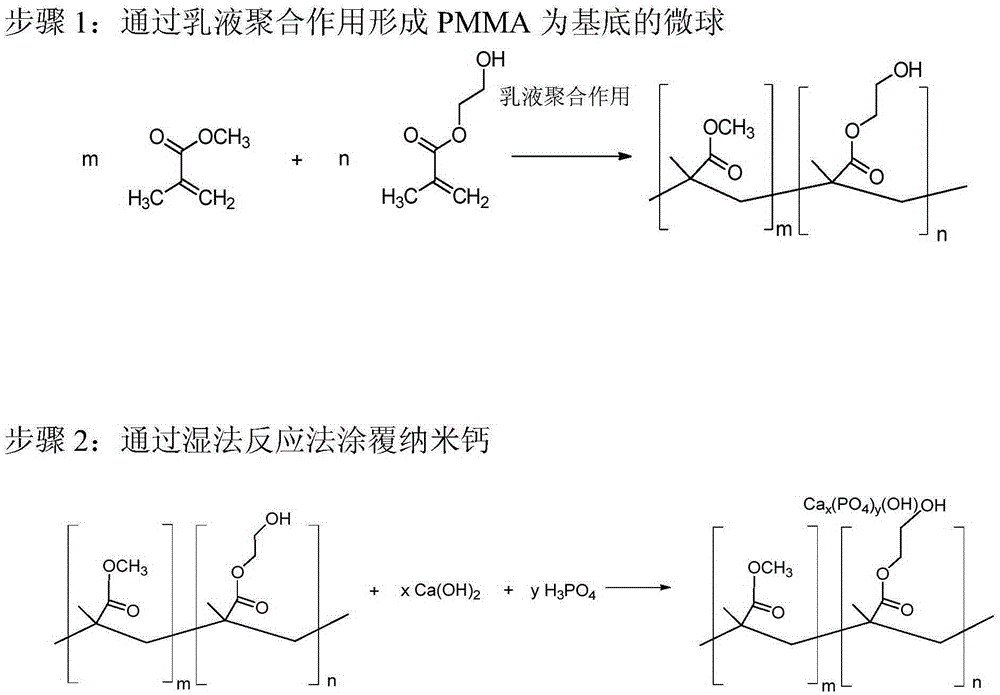

[0034] Example 1, the synthesis of PMMA containing hydroxyl side groups is the copolymer microsphere of substrate

[0035]PMMA-based copolymer microspheres containing one or more hydroxyl side groups were synthesized by emulsion polymerization. Generally, a combination of monomers (methyl methacrylate, or other methacrylate monomers with pendant hydroxyl groups (e.g., 2-hydroxyethyl methacrylate)), distilled water, and potassium peroxodisulfate , and heated at 80 °C for 3 h in a nitrogen atmosphere. Then, the mixture was centrifuged and washed with distilled water. The PMMA-based microspheres were dried using a freeze dryer.

[0036] The types of PMMA-based microspheres synthesized are summarized in Table 1.

[0037]

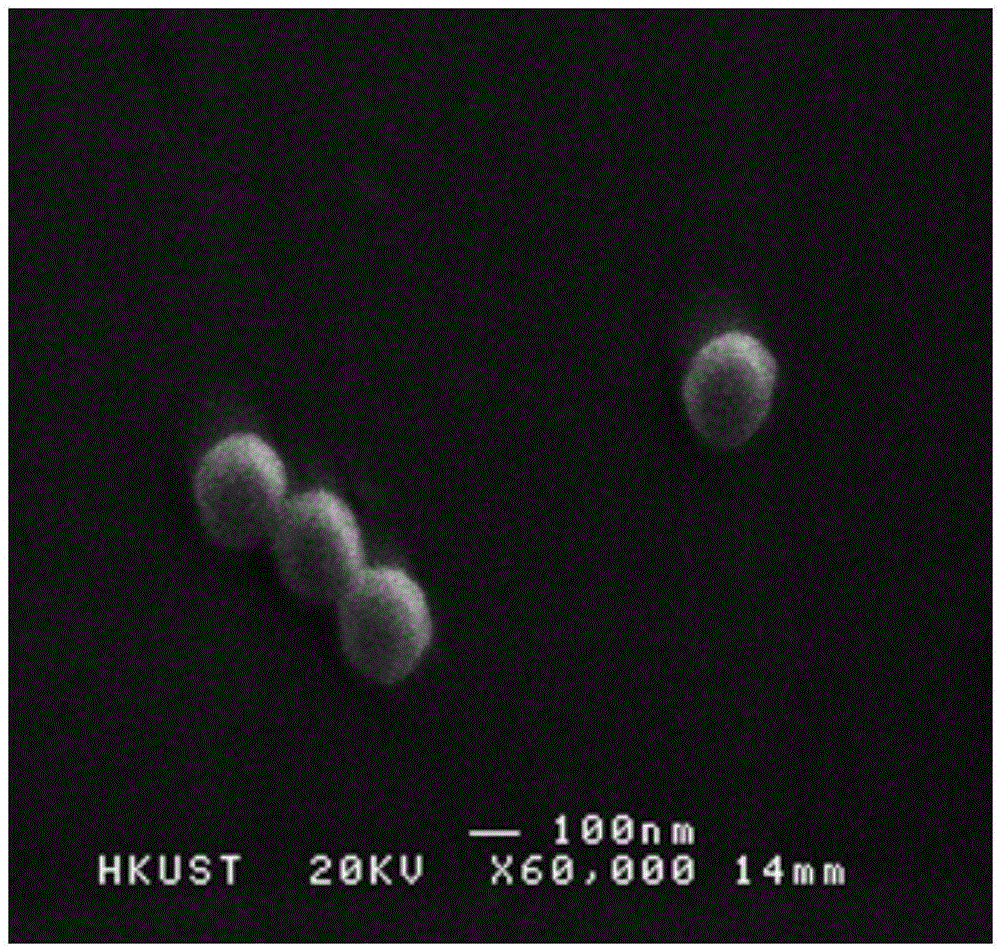

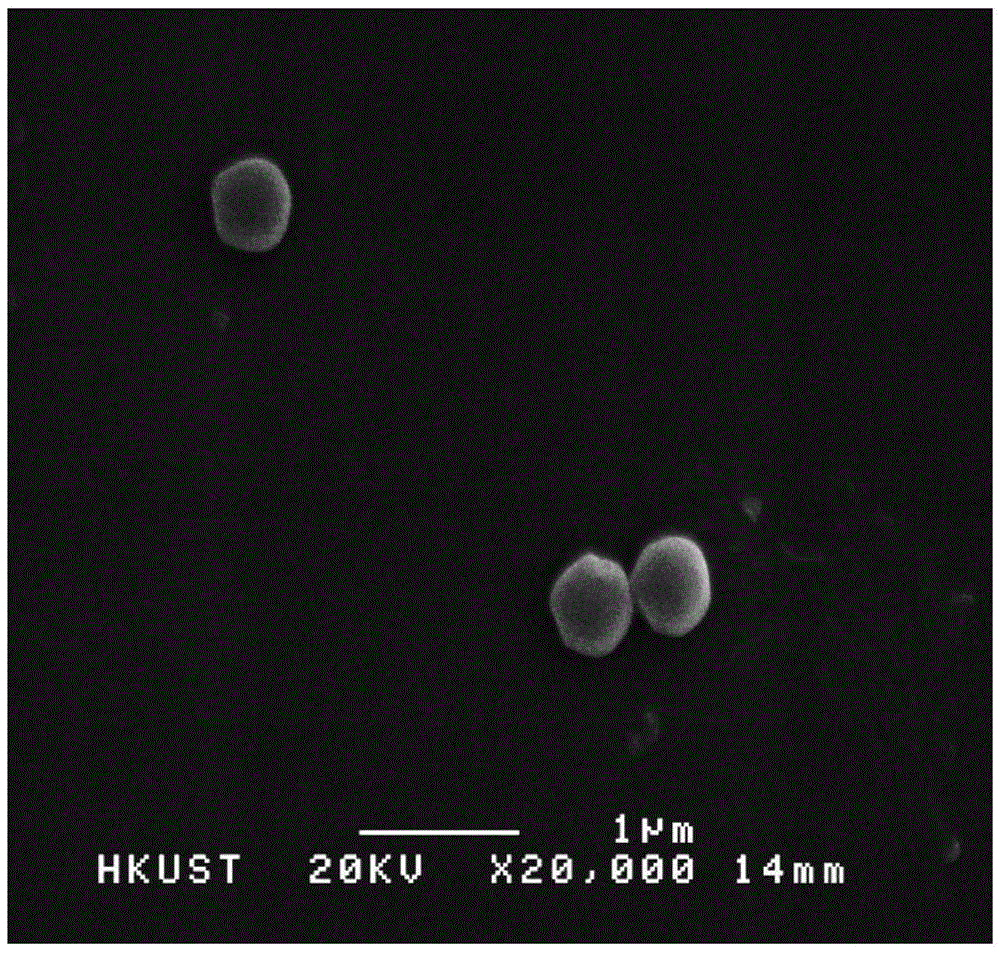

[0038] PMMA-based microspheres (P, PH-1 and PH-0.5) were characterized using scanning electron microscopy (SEM). Figure 2-4 SEM images of PMMA-based microspheres are shown.

example 2

[0039] Example 2, PMMA is the nano calcium phosphate coating on the copolymer microsphere of substrate

[0040] PMMA-based microspheres (pH-0.5) and calcium hydroxide were mixed with distilled water in a beaker. Phosphoric acid was added dropwise to the reaction mixture using a syringe pump at a rate of 0.139 ml / hr. After all the phosphoric acid had been added, the reaction mixture was mixed for 1, 2 and 3 days, respectively. After complete mixing, the mixture was centrifuged and freeze-dried.

[0041] The PMMA-based copolymer microspheres coated with nano-calcium phosphate were observed by scanning electron microscopy (SEM), and the PMMA-based copolymer microspheres coated with nano-calcium phosphate were analyzed by energy dispersive X-ray (energy dispersive X-ray, EDX). ball. Nanocalcium phosphate-coated PMMA-based microspheres were immobilized on silicon wafers and coated with carbon for SEM observation. Figure 5-7 The SEM images of the reaction products after 1, 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com