Sludge dewatering conditioning agent and dewatering method thereof

A sludge dehydration and conditioner technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of poor economy, complicated preparation process, large specific surface area, etc., achieve improved stability and reliability, and simple conditioning process , the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The sludge is the remaining sludge from the secondary settling tank of the cold rolling wastewater treatment station of a stainless steel enterprise, with a moisture content of 98%; the desulfurization ash is a by-product of the sintering flue gas purification device obtained from a circulating fluidized bed process in a steel factory, of which CaSO 3 1 / 2H 2 O, CaCO 3 , f-CaO and Ca(OH) 2 The total mass fraction of the four substances is 85%.

[0051] Magnesium chloride, ferric sulfate, aluminum sulfate, and magnesium oxide are commercially available products with industrial grade purity.

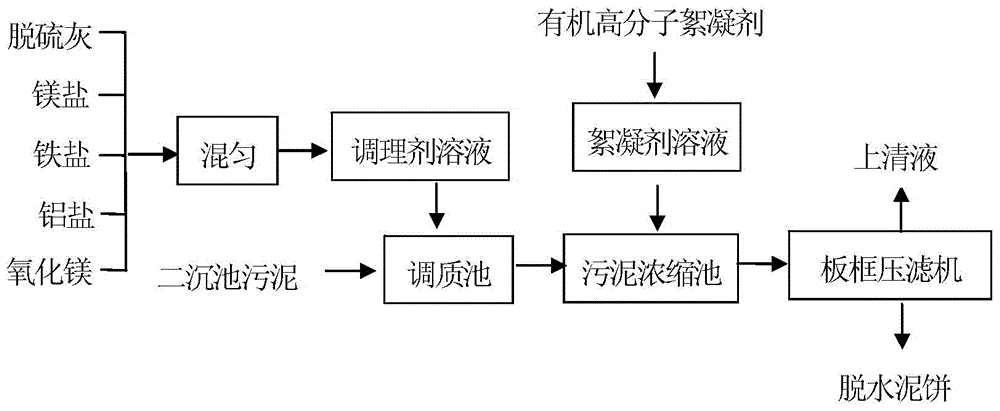

[0052] Such as figure 1 As shown, mix desulfurization ash, magnesium chloride, iron sulfate, aluminum sulfate, and magnesium oxide according to the weight percentage of 50%, 10%, 30%, 5%, and 5%, and add water to make a solution; according to the dry weight of sludge 3 %, add it into the conditioning tank, stir evenly, and after conditioning for 60 minutes, pump it into the slud...

Embodiment 2

[0058] The sludge is the remaining sludge from the secondary settling tank of an urban domestic sewage plant, with a moisture content of 97.5%; the desulfurization ash is the by-product of the sintering flue gas purification device obtained by the rotary spraying process of a steel factory, in which CaSO 3 1 / 2H 2 O, CaCO 3 , f-CaO and Ca(OH) 2 The total mass fraction of the four substances is 95%.

[0059] Magnesium phosphate, ferric chloride, polyaluminum ferric sulfate, and magnesium oxide are commercially available products with industrial grade purity.

[0060] Such as figure 1 As shown, mix desulfurization ash, magnesium chloride, iron sulfate, aluminum sulfate, and magnesium oxide according to the weight percentage of 70%, 10%, 10%, and 10%, and add water to make a solution; according to the proportion of 30% of the dry weight of sludge , into the conditioning tank, stir evenly, after conditioning for 20 minutes, pump into the sludge thickening tank.

[0061] Dissol...

Embodiment 3

[0064] The sludge is the remaining sludge from the secondary settling tank of a waterworks, with a moisture content of 99%; the desulfurization ash is the by-product of the purification and sintering flue gas purification device of a steel factory furnace with calcium oxide activation process, in which CaSO 3 1 / 2H 2 O, CaCO 3 , f-CaO and Ca(OH) 2 The total mass fraction of the four substances is 50%.

[0065] Magnesium sulfate, ferric sulfate, polyaluminum ferric sulfate, and magnesium oxide are commercially available products with industrial grade purity.

[0066] Such as figure 1 As shown, mix desulfurization ash, magnesium chloride, ferric sulfate, polyaluminum chloride, and magnesium oxide according to the weight percentage of 30%, 15%, 30%, 10%, and 15%, and add water to make a solution; Add 20% weight to the conditioning tank, stir evenly, and pump it into the sludge thickening tank after conditioning for 50 minutes.

[0067] Dissolve the anionic polyacrylamide with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com