Sliding block balanced oil cylinder system without external pipeline

A technology for balancing oil cylinders and external pipes, which is applied in the direction of presses, fluid pressure actuators, manufacturing tools, etc., can solve the problems of human and equipment loss, low safety factor, and exceeding pipelines, etc. The effect of reducing flow velocity loss and high oil replenishment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

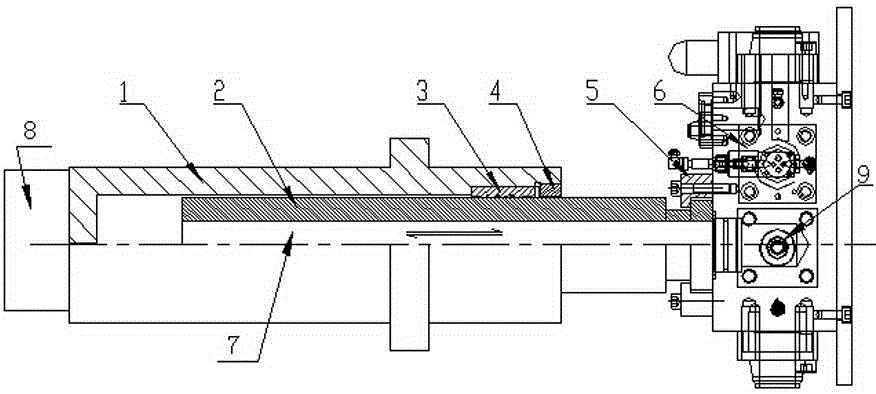

[0013] The present invention as figure 1 shown.

[0014] A slider balance oil cylinder system without external pipelines, including a valve body 6 and a slider 8, the valve body 6 is directly fixedly connected to the plunger cylinder rod 2 through the flange 5, and the plunger cylinder rod 2 The inner cavity is a through pipeline 7, which communicates with the electromagnetic ball valve 9 in the valve body 6 through the flange 5; the cylinder rod 2 of the plunger cylinder is covered with the cylinder body 1, and the top of the cylinder body 1 is connected with the slider 8 The tail end of the cylinder body 1 is fixedly connected with the end cover 4 .

[0015] A sealing sleeve 3 is also provided between the tail end of the cylinder body 1 and the end cover 4, and the sealing sleeve 3 cooperates with the plunger cylinder cylinder rod 2 on the inner wall of the cylinder body 1 to form a sealing structure.

[0016] The sliding block balancing oil cylinder system connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com