Self-flowing soldering method and system for laser welding

A laser welding and self-flowing technology, which is applied in the field of laser automatic welding, can solve problems such as difficulty in eating soldering iron tip, short shelf life, easy corrosion of soldering iron tip, etc., and achieve the effect of easy guarantee of processing accuracy, simple use method and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

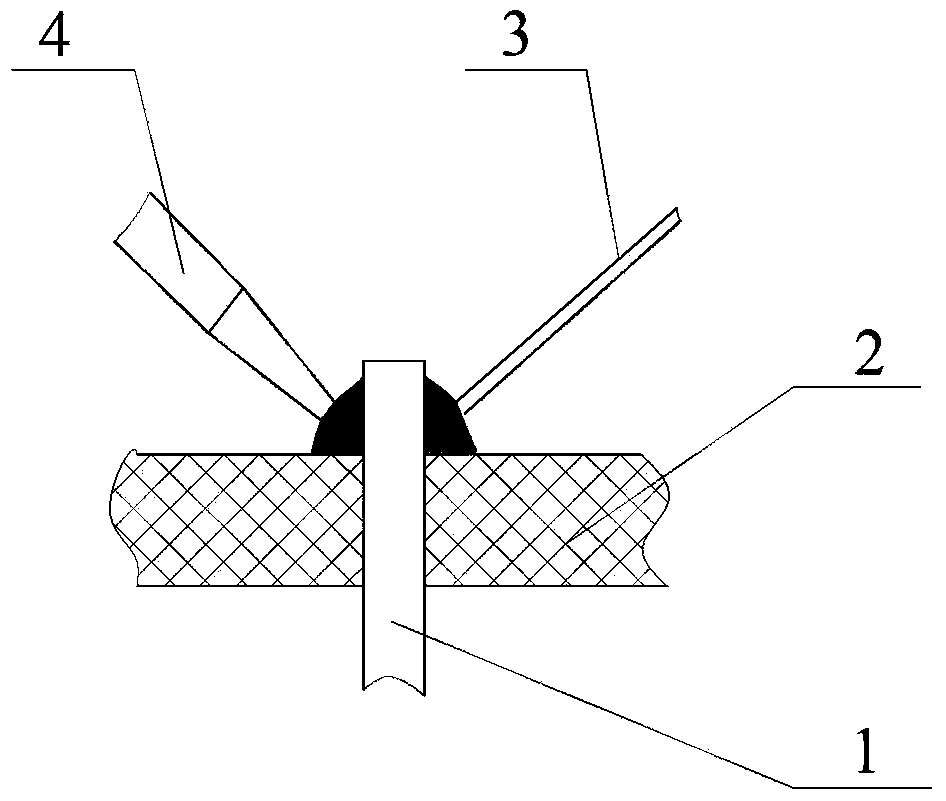

[0033] The present invention is a self-flowing soldering method for laser welding. The solid-phase tin is converted into liquid-phase tin by means of electric heating and then stored, and kept in a liquid-phase state; after the liquid-phase tin is flowed onto the pad, Since the pad is cold liquid-phase tin into a solid-phase solder joint, the laser is used to heat the solder joint at this time, so that the tin is well infiltrated on the pad.

[0034] When transporting tin in the liquid phase, the flow of tin in the liquid phase is controlled by controlling the pressure.

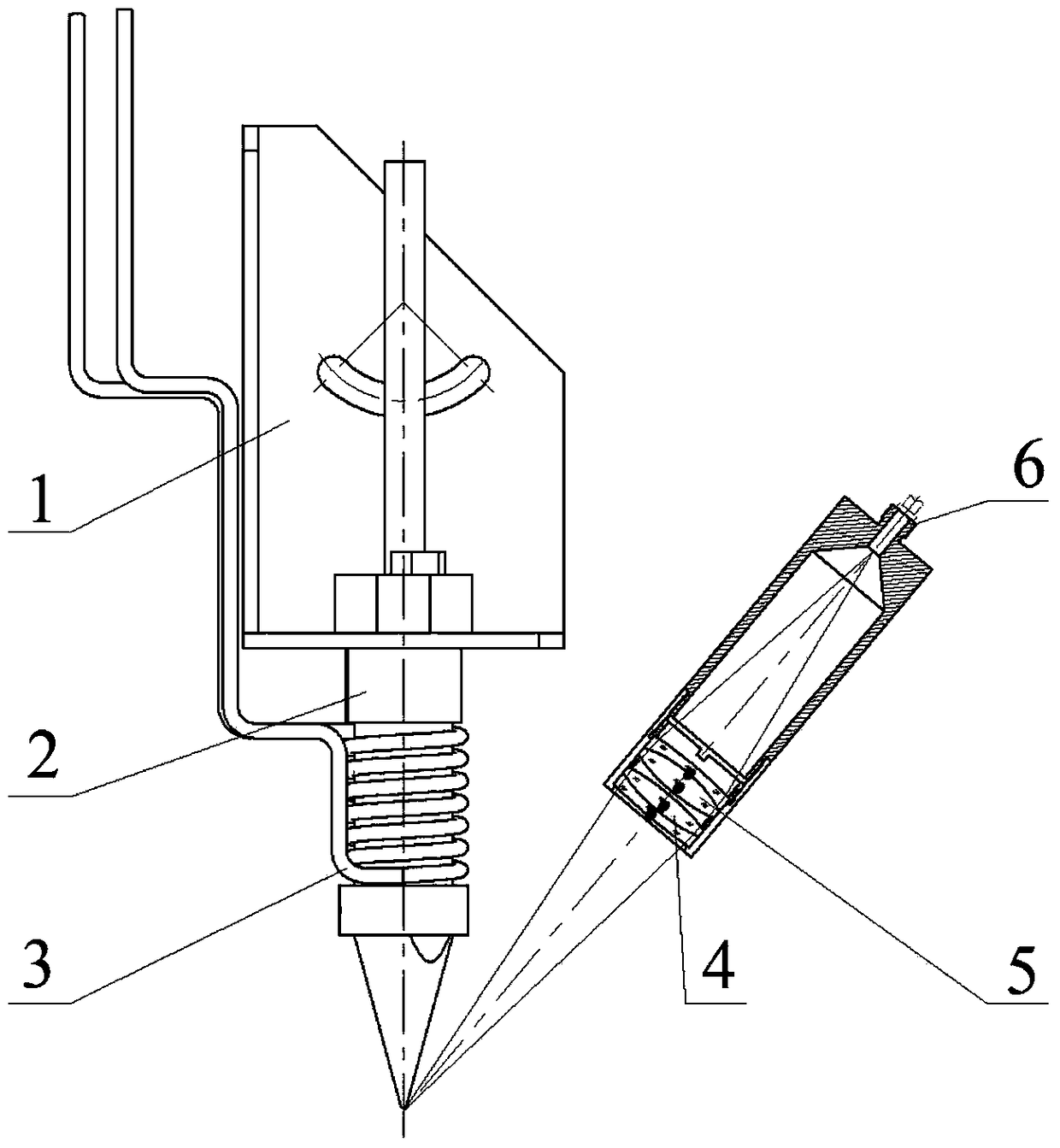

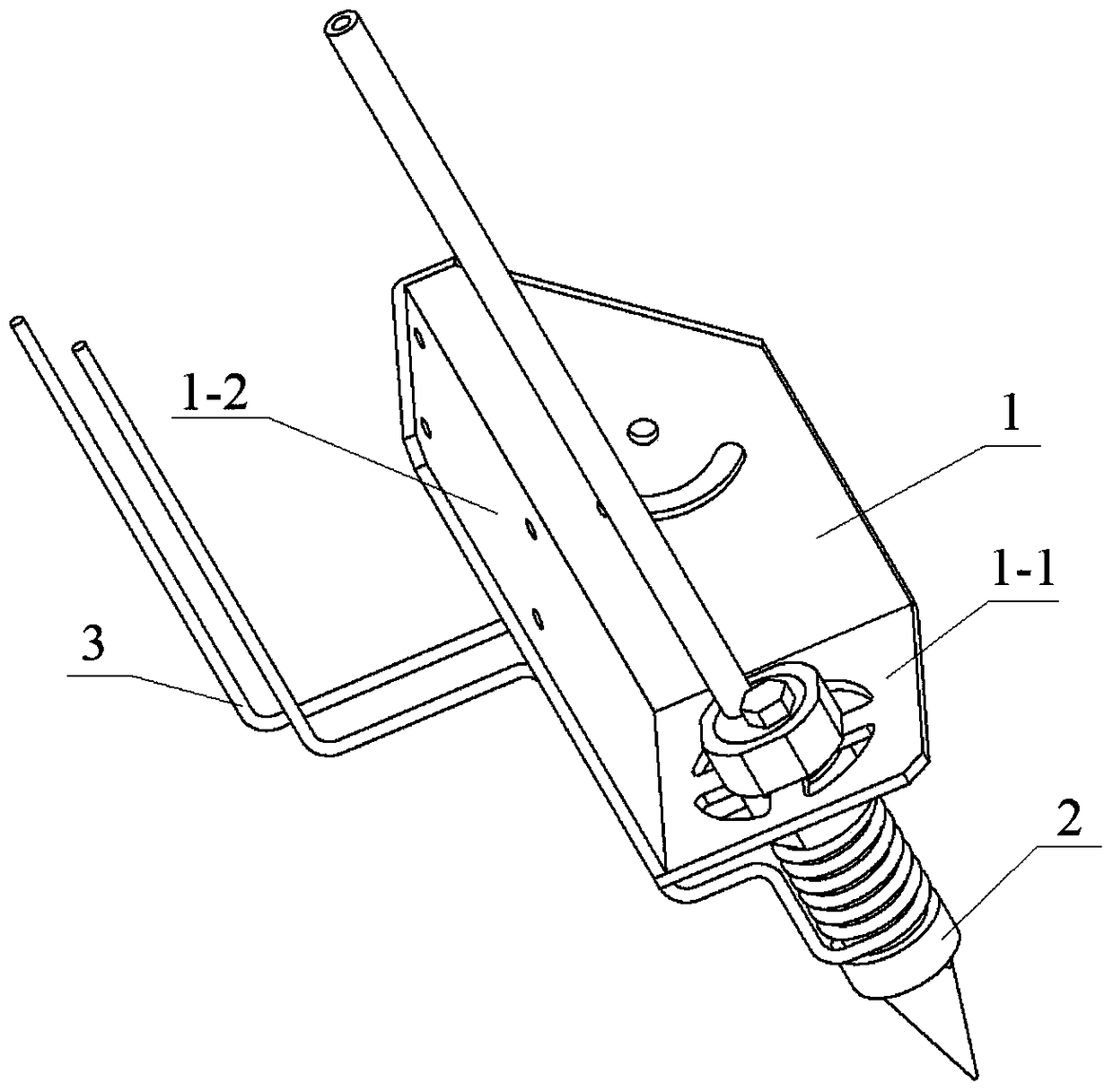

[0035] A self-flowing soldering system for laser welding, comprising

[0036] Focusing head, the focusing head is used to focus the laser on the welding spot fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com