Overturn seal testing and marking apparatus

A technology of sealing test and turning bracket, which is applied in the direction of fluid tightness test, measuring device, machine/structural component test, etc. It can solve the problems of increasing equipment procurement and maintenance costs, affecting product assembly quality, and difficult to guarantee product quality, etc. , to reduce equipment procurement and maintenance costs, easy to guarantee product quality, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

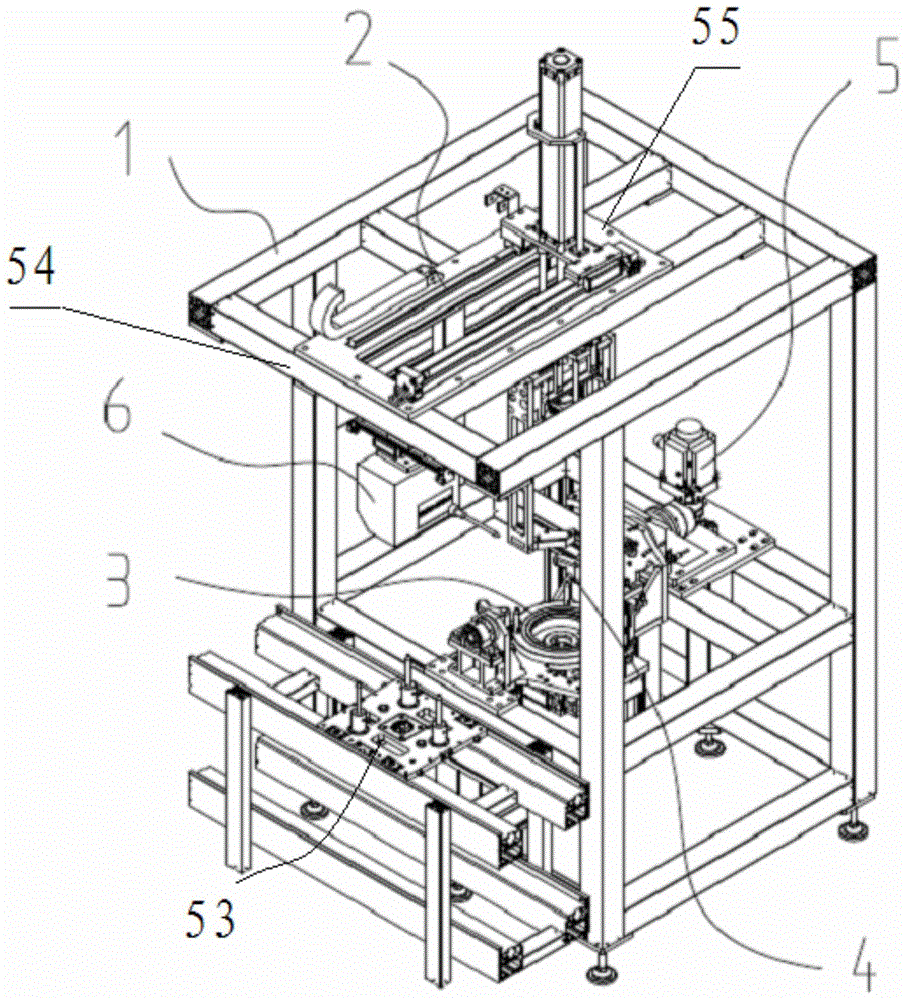

[0035] Such as figure 1 As shown, the present invention includes a bracket 1, a transport mechanism 2, a positioning mechanism 3, a rotation locking mechanism 4, a turning mechanism 5 and a marking mechanism 6, wherein the positioning mechanism 3 and the rotation locking mechanism 4 work together through the turning mechanism 5 Flip movement, all mechanisms are installed on the bracket 1.

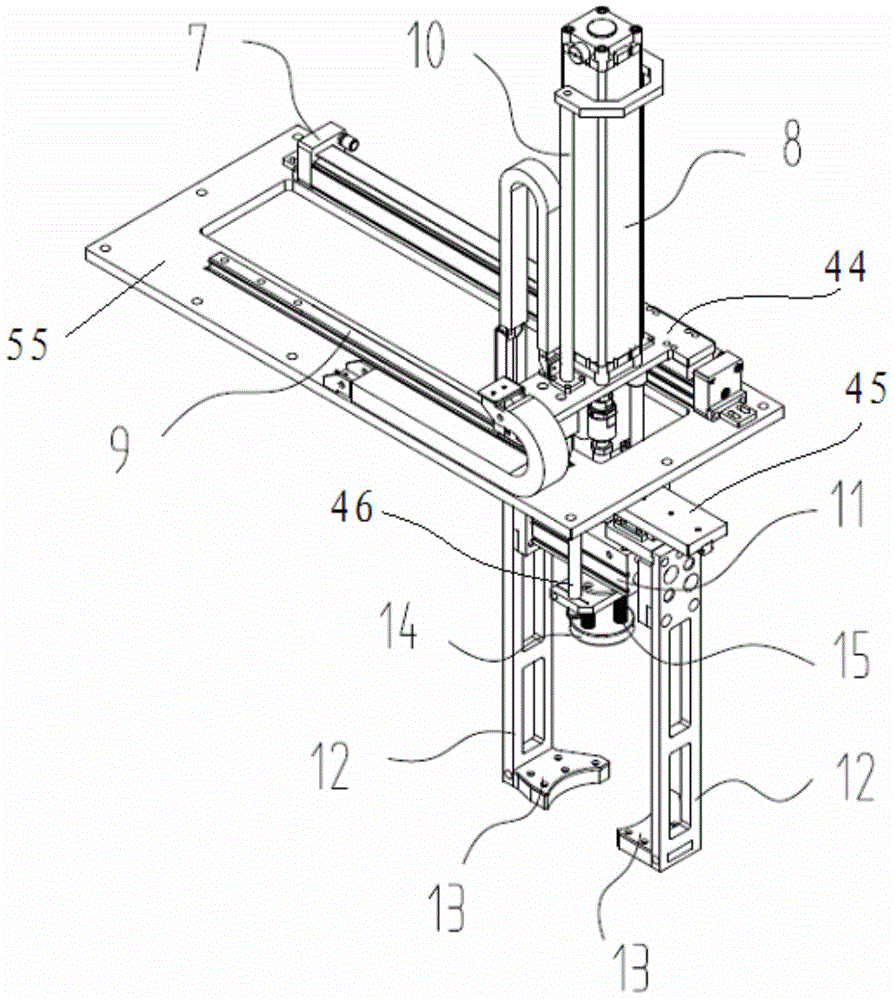

[0036] Carrying mechanism 2 is installed on the crossbeam of support 1 top by mounting plate 55, as Figure 2~3As shown, the transfer mechanism 2 includes a translation cylinder 7, a lifting cylinder 8, a guide rail 9, a guide mechanism 10, a clamping air claw 11 and a support plate 44, wherein the translation cylinder 7 is a rodless cylinder, and one end of the support plate 44 is installed on On the moving block of the translation cylinder 7, the other end is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com