Pre-stress arm structure of aluminum alloy door window

一种铝合金门窗、预应力的技术

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below in conjunction with specific examples.

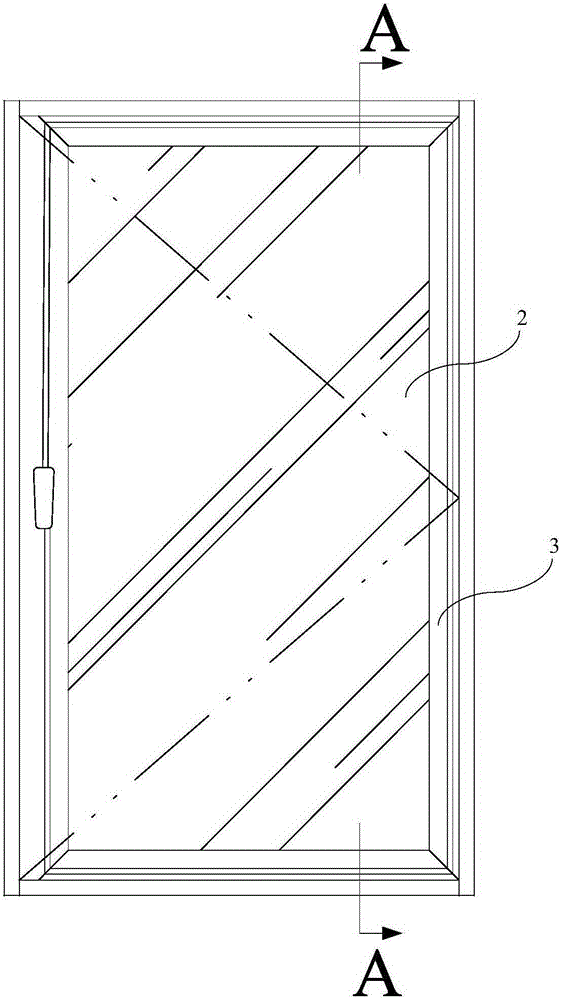

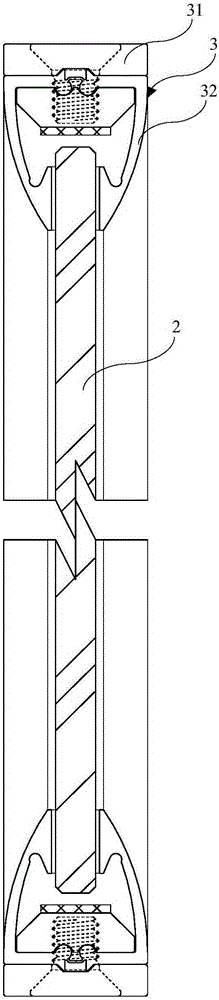

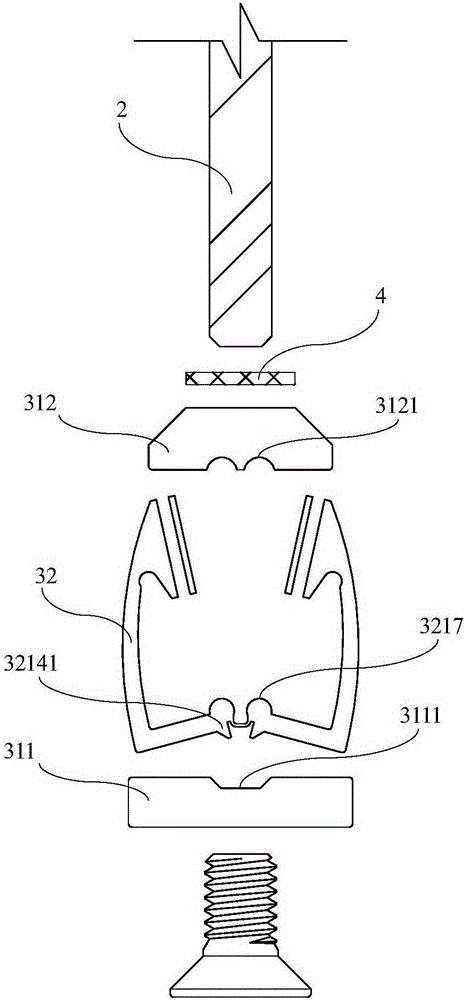

[0081] In the first preferred embodiment of the present invention, an aluminum alloy door and window of the present invention, please refer to Figure 1-3 , including a glass door form 2 fixed in the frame 3; the frame 3 includes a pressing component 31 and a fastening component 32, the pressing component 31 cooperates with the glass door form 2 to press the fastening component 32 to generate prestress and then fasten the glass door form 2.

[0082] see Figure 4-7, the fastening assembly 32 includes two bow-shaped arms 321 symmetrically clamped on both sides of the glass door window body 2, and its material should be selected from a material with considerable strength and a certain degree of elasticity and toughness, such as metal, engineering plastics, polymer materials, etc. Etc. An enclosed space 320 is formed between the two arched arms 321, the arched arms 321 include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com