Sludge dewatering and concentration treatment fundamental technology

A technology for sludge dehydration and process, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. and other problems, to achieve the effect of short construction period, low sludge moisture content and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1-sludge treatment produced by a certain urban domestic sewage treatment plant

[0036] Sludge indicators and post-treatment requirements are:

[0037]

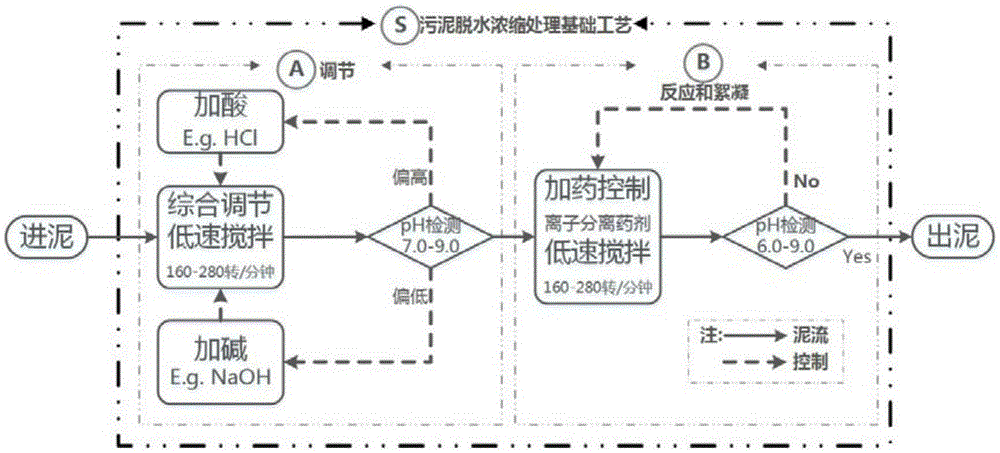

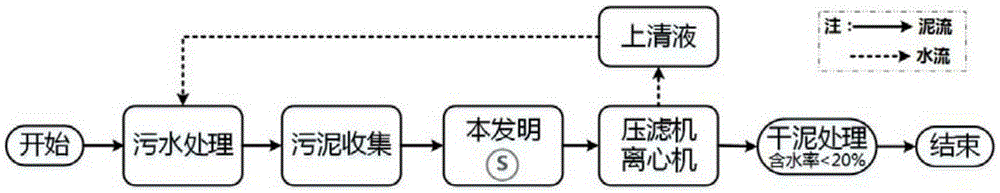

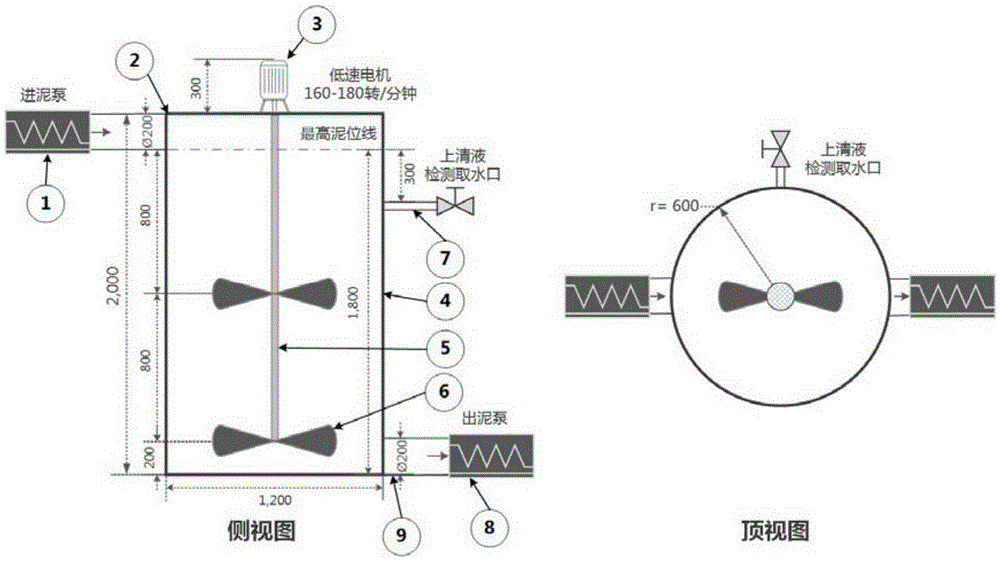

[0038] The flowchart of the sludge dehydration and concentration treatment basic process disclosed by the present invention is as follows: figure 1 As shown, there are two sub-processes including A-regulation, B-reaction and flocculation. The detailed sub-process and each process point process, parameters, control and operation method steps are described as follows:

[0039] A. Adjustment: The sludge with the working conditions of the ion separation agent is introduced here, mainly including several links such as comprehensive adjustment, slow stirring and pH detection. The details are as follows:

[0040] 1) Requirements for mud entry: This sub-process is the first sub-process of the present invention, and the source of mud entry is the sludge produced by sewage treatment, and no chemical flocculant i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com