Infiltration reaction wall composite material for underwater polyaromatic hydrocarbon pollution remediation as well as preparation method and application method of Infiltration reaction wall composite material

A technology for polycyclic aromatic hydrocarbons and pollution remediation, applied in water pollutants, contaminated groundwater/leachate treatment, chemical instruments and methods, etc., can solve problems such as insufficient oxygen supply and difficult control of carbon source release, and achieve long-term maintenance Carbon source, significant removal effect, and long-term effective removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

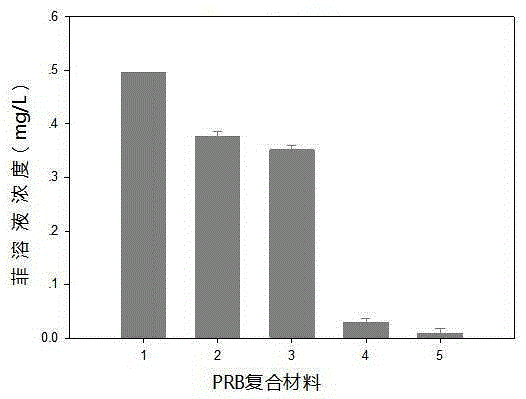

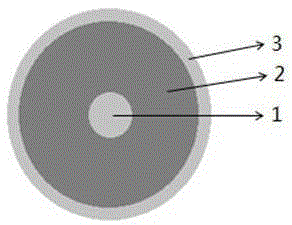

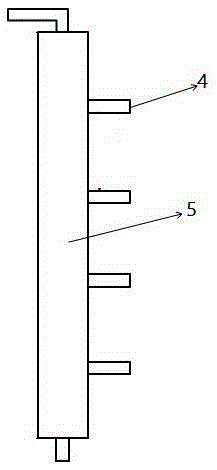

Embodiment 1

[0045] It is a composite material for chemical and biological remediation of organically polluted groundwater. Its core is coconut shell biochar spherical particles, and its filling layer is composed of the following components by mass percentage: oxygen release agent calcium peroxide 15.85%, which mainly provides oxygen for microbial degradation of pollutants 31.7% of carbon-releasing raw material coconut shell biochar, mainly to maintain the carbon source required for microbial growth; 15.85% of plastic bonding raw material attapulgite, mainly to bond all raw materials and maintain a certain hardness; high permeability raw material silicon Alginate 6.6%, mainly to keep the composite material porous, which can release oxygen source and carbon source slowly; binder sodium alginate 29.98%. The shell has the function of covering and protecting, and is composed of the following components by mass percentage: 13.84% of ordinary portland cement for plastic bonding, 41.53% of attapul...

Embodiment 2

[0058] This embodiment is used for organically polluted groundwater chemical bioremediation composite material, basically the same as embodiment 1, the difference is: its inner core is peach kernel biochar spherical particles, the particle size is 0.5cm, and its material filling layer is composed of the following mass percentage Component composition: oxygen release agent calcium peroxide 15.09%; carbon release raw material peach pit biochar 30.19%; plastic bonding raw material attapulgite 15.09%; high permeability raw material diatomite 6.29%; binder sodium alginate 33.33%. The shell is composed of the following components in mass percentage: 13.39% of ordinary Portland cement as a plastic bonding material, 40.18% of attapulgite, 6.43% of diatomite as a high-permeability material, and 40% of sodium alginate as a binder. The particle diameters of the oxygen-releasing agent, carbon-releasing raw material, plastic bonding raw material, high-permeability raw material and sodium a...

Embodiment 3

[0071] The present embodiment is the same as Example 1, and its inner core is coconut shell biochar spherical particles, and its filling layer is made up of the following components by mass percentage: 15.50% of oxygen-releasing agent calcium peroxide; 31% of carbon-releasing raw material coconut shell biochar; plasticity The bonding raw material attapulgite is 15.50%; the high permeability raw material diatomite is 6.45%; the binder sodium alginate is 31.52%. The shell has the function of covering and protecting, and is composed of the following components by mass percentage: 13.6% of ordinary Portland cement as a plastic bonding material, 40.8% of attapulgite, 6.53% of diatomite as a high-permeability raw material, seaweed as an adhesive Sodium acid 38.07%. The particle diameters of the oxygen-releasing agent, carbon-releasing raw material, plastic bonding raw material, high-permeability raw material and sodium alginate used in the composite functional material of this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com