Visual-positioning mobile phone accessory attaching system

A visual positioning and placement system technology, applied in packaging, labeling machines, transportation and packaging, etc., can solve the problems of low cost performance, low efficiency, and reduced efficiency, and achieve low cost of line replacement, low production process requirements, and reduced The effect of the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

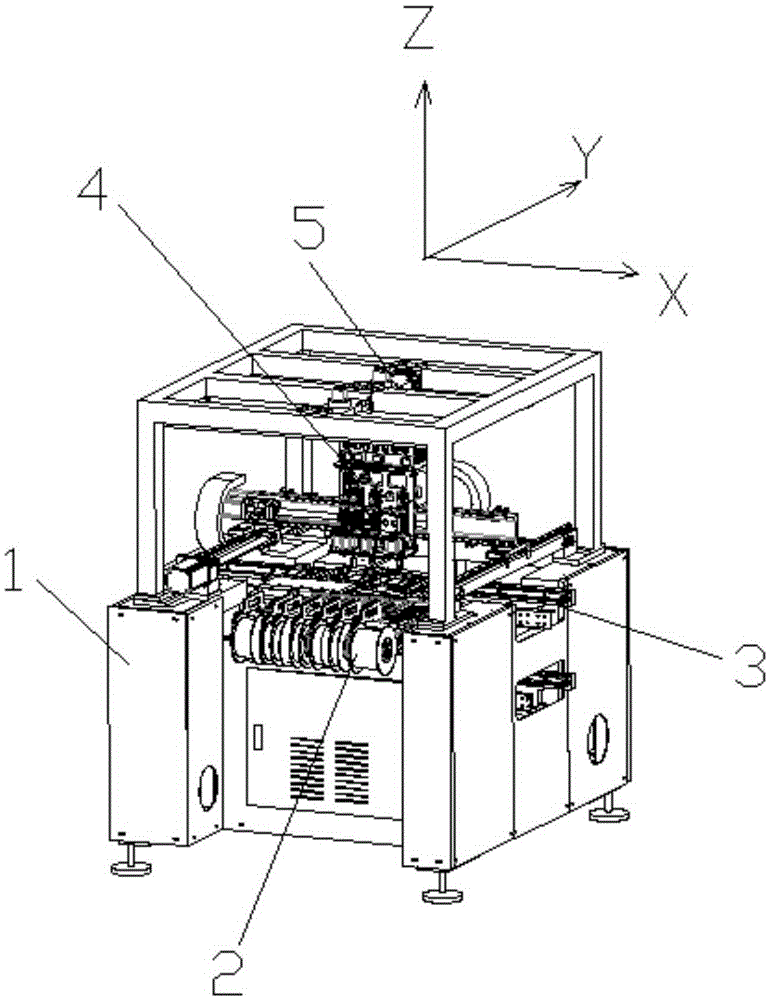

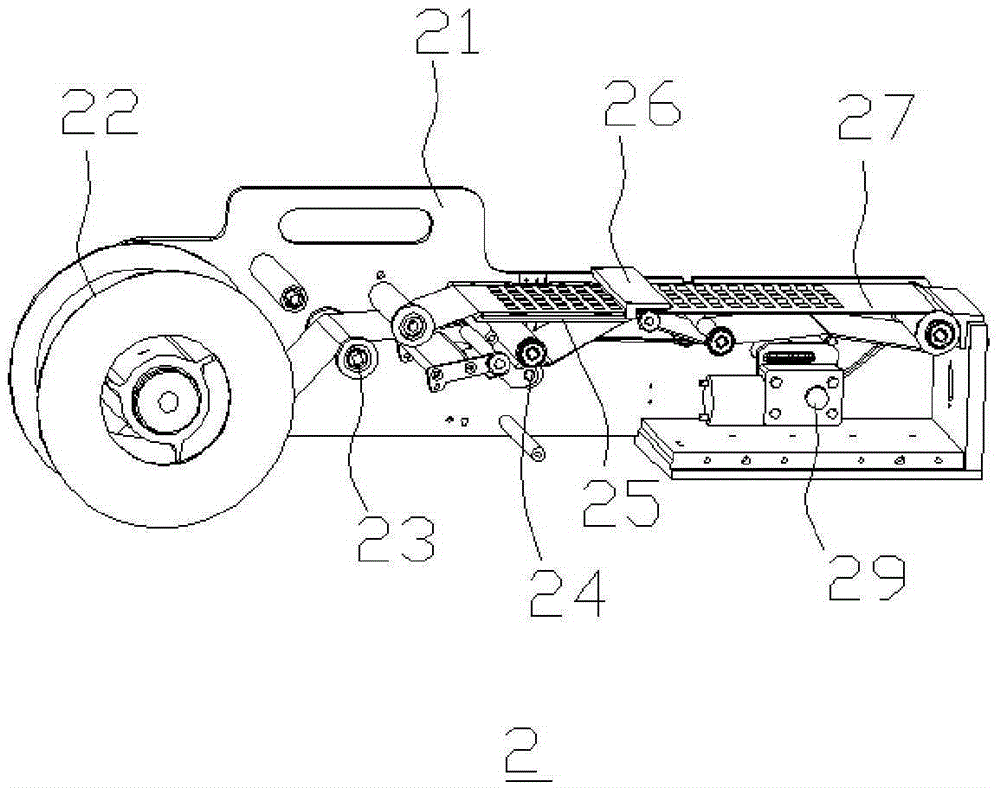

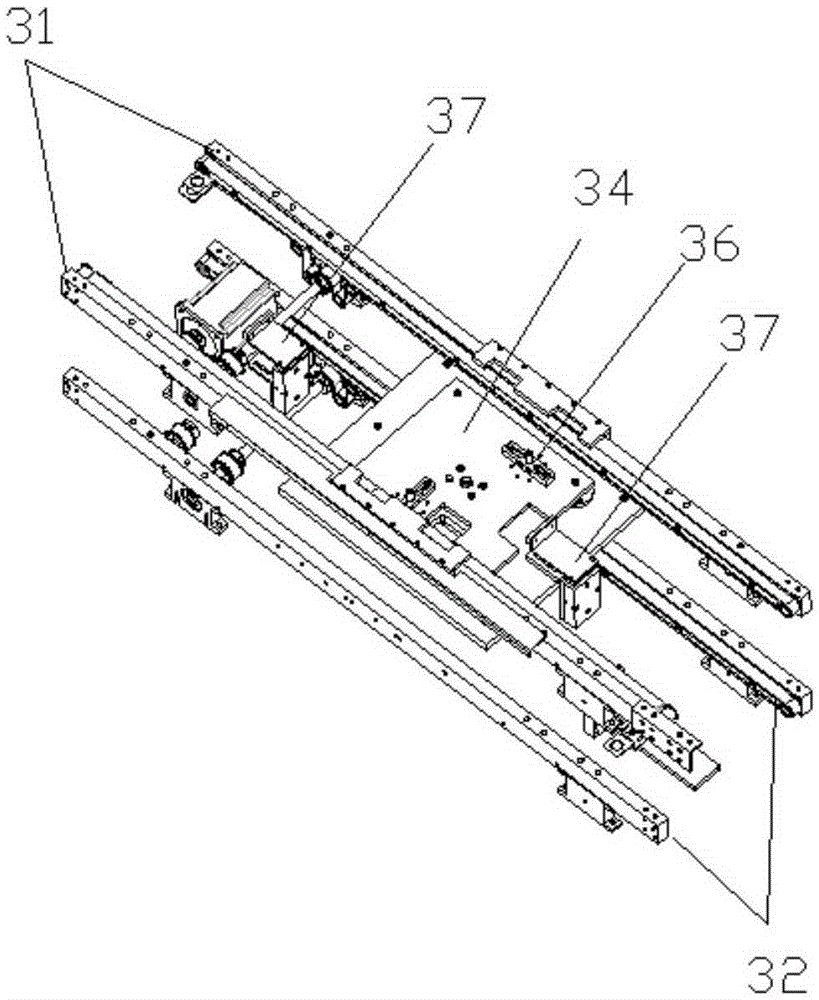

[0033] figure 1 Embodiment 1 of the mobile phone auxiliary material placement system for visual positioning, including the main frame 1, the auxiliary material stripping mechanism 2, the feeding and discharging mechanism 3, the placement actuator 4, the visual positioning mechanism 5, the controller (not shown in the figure), the host Frame 1 is a three-dimensional frame with X-axis, Y-axis, and Z-axis directions; six auxiliary material stripping mechanisms 2 are installed on the front of the main frame 1, and the feeding and discharging mechanism 3 passes through the middle of the main frame 1 and is adjacent to the rear of the auxiliary material stripping mechanism 2 The auxiliary material belt, the feeding and discharging mechanism 3 is provided with a placement execution area close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com