Self-locking type integrated lifting mechanism

A lifting mechanism and self-locking technology, applied in the field of integrated lifting mechanism, can solve the problems of structural redundancy, angle offset, low stability, etc., and achieve simple and reasonable structural design, increased bending moment resistance, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

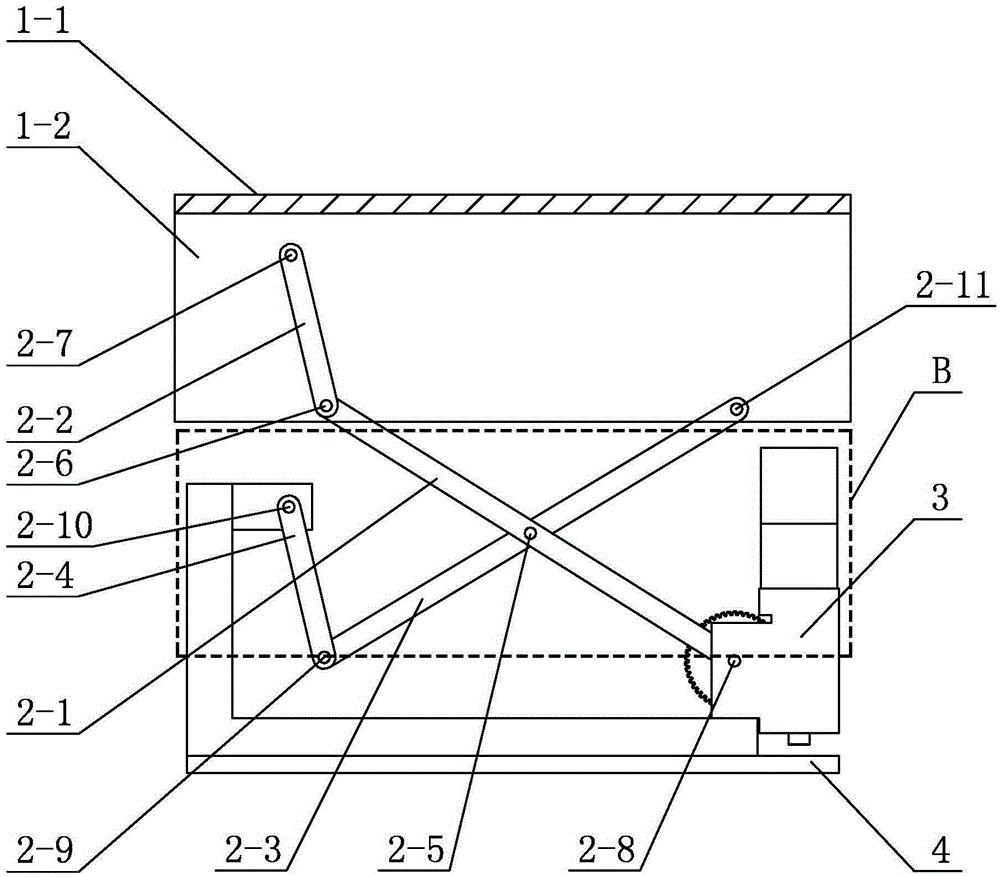

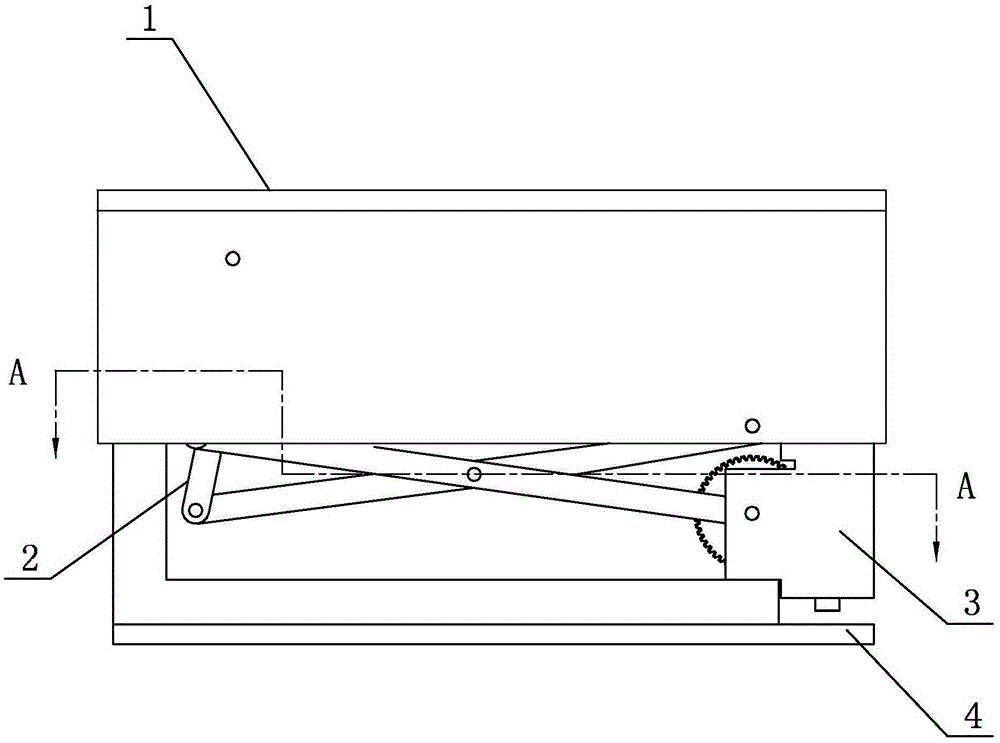

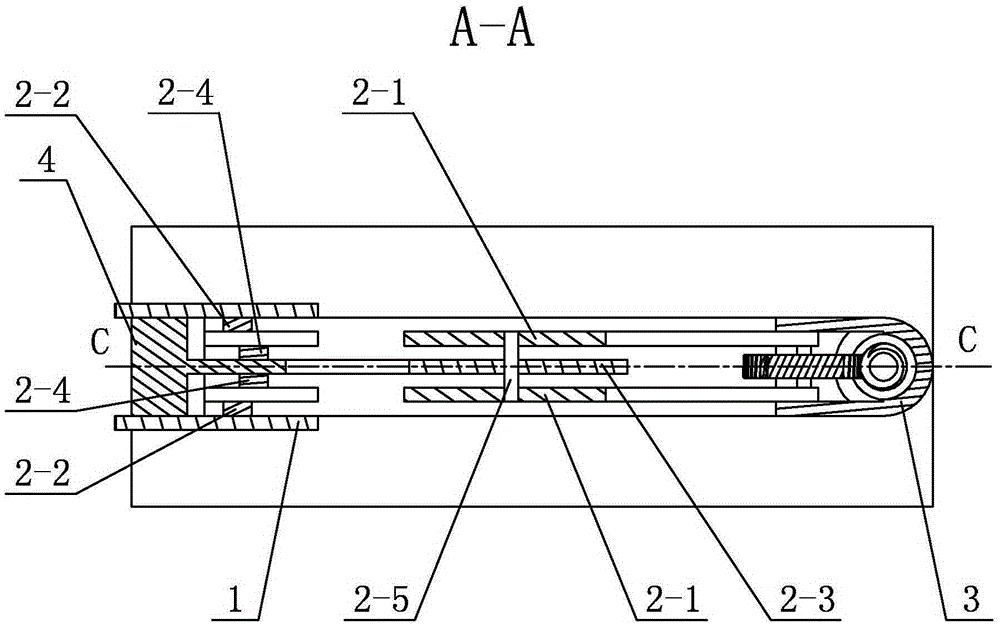

[0021] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Describe this embodiment. This embodiment includes a lifting platform 1, a connecting rod movement module 2, a driving module 3 and a fixed frame 4. The connecting rod moving module 2 is arranged on the fixing frame 4, and the lifting platform 1 is arranged on the connecting rod On the movement module 2, the drive module 3 is inlaid on the fixed frame 4 and connected with the link movement module 2;

[0022] The lifting platform 1 includes a top board 1-1 and two side boards 1-2, the top board 1-1 is arranged horizontally, and the two side boards 1-2 are arranged vertically and side by side under the top board 1-1;

[0023] The drive module 3 includes a drive motor 3-1, a worm screw 3-2 and a worm wheel 3-3, the output shaft of the drive motor 3-1 is connected to the worm screw 3-2, and the worm wheel 3-3 is connected to the worm screw 3-2. 2 meshing;

...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 , figure 2 and image 3 To illustrate this embodiment, the drive module 3 in this embodiment also includes a motor fixing seat 3-7, a coupling 3-8, a top bearing 3-4, a driving fixing seat 3-5, and a bottom bearing 3-6, The drive mount 3-5 is arranged vertically, and the shaft coupling 3-8, the top end bearing 3-4 and the bottom end bearing 3-6 are sequentially arranged on the drive mount 3-5 from top to bottom. The worm 3-2 is arranged between the top bearing 3-4 and the bottom bearing 3-6, the motor holder 3-7 is fixedly connected to the top of the drive holder 3-5, and the drive motor 3-1 is arranged on On the motor fixing seat 3-7, the output shaft of the driving motor 3-1 is connected with the worm screw 3-2 through a shaft coupling 3-8.

[0030] In the present invention, the mutual motion between the lifting platform 1, the first homologous output link 2-2 and the coupling link 2-3 is the first revolving p...

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 1 , figure 2 , Figure 5 and Figure 6 Describe this embodiment, in this embodiment, the fixed frame 4 includes an L-shaped fixed plate 4-1, a connecting plate 4-2 for a link movement module and a bottom plate 4-3, the bottom plate 4-3 is horizontally arranged, and the The L-shaped fixed plate 4-1 is vertically arranged on the bottom plate 4-3, and the bottom of the drive fixed seat 3-5 is clamped on the horizontal end of the L-shaped fixed plate 4-1, and the L-shaped fixed plate 4- The vertical end of 1 is fixedly connected with the connecting plate 4-2 for the connecting rod movement module arranged horizontally, and the other end of each second homologous output connecting rod 2-4 is hinged on the connecting plate 4-2 for the connecting rod moving module. 2 on. The layout of the fixed frame 4 arranged in this way is reasonable, so that it takes up little space. Other structures and connections are the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com