Organic fertilizer fish type raw material crushing equipment

A technology of crushing equipment and organic fertilizer, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, grain processing, etc., can solve problems such as corrosion, and achieve the effect of improving stability, improving transmission stability, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 is basically as attached figure 1 Shown:

[0035] The crushing equipment for organic fat fish raw materials includes an outer cylinder 100 and a rotating roller 101 vertically rotatably connected in the outer cylinder 100. A supporting ring 102 is fixed in the outer cylinder 100. The supporting ring 102 is arranged near the lower part of the rotating roller 101. The supporting ring A plurality of supporting frames 103 are fixed between the outer cylinder 102 and the outer cylinder 100 , wherein the rotating roller 101 and the supporting ring 102 are rotatably connected. The upper end of the rotating roller 101 protrudes from the outer cylinder 100, wherein the outer cylinder 100 is supported on the bottom surface of the processing plant or other places through the frame, and the top of the outer cylinder 100 is provided with a feed hopper 104, and the bottom of the outer cylinder 100 is fixed. The conical bucket 105 is provided with a discharge valve 106 a...

Embodiment 2

[0040] Embodiment 2 is basically as attached Figure 4 Shown:

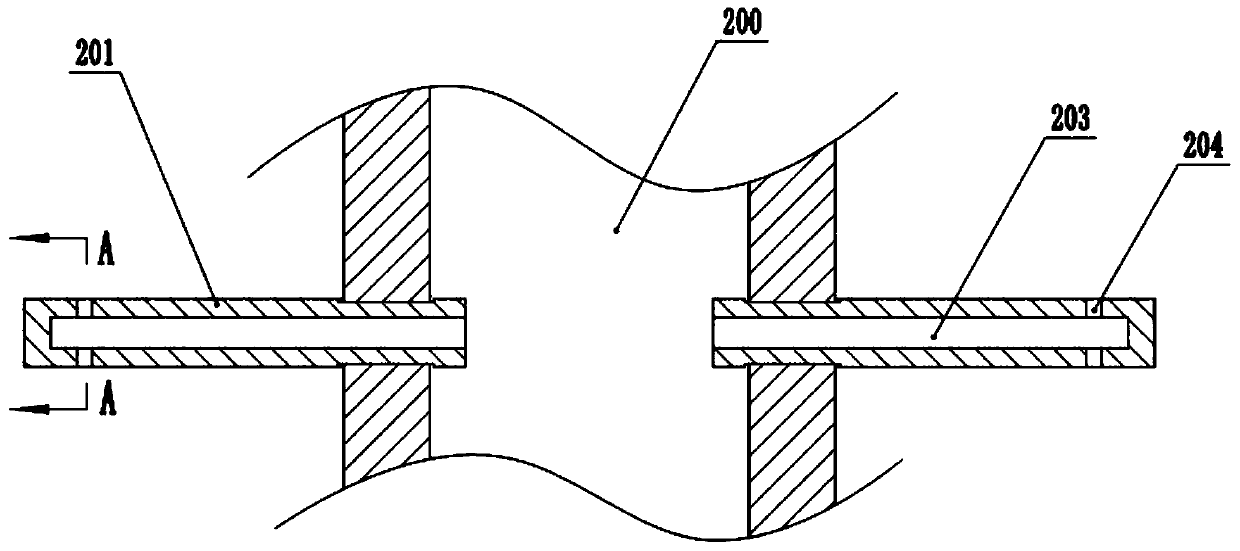

[0041]The difference from Embodiment 1 is that a drain hole 206 connected to the cleaning chamber II 203 is provided at the end of the crushing column I 201 , the drain hole 206 is bell-shaped, and the small diameter end of the drain hole 206 is close to the cleaning chamber II 203 .

[0042] Since the crushing column I 201 rotates with the roller 101, part of the raw materials will remain at the root between the adjacent crushing columns II 202, so the drainage hole 206 is set to wash away the remaining raw materials through the impact of the water flow. It should be noted that since the crushing column I 201 is constantly revolving with the rotating roller 101, the water flow has a certain inclination angle due to the centrifugal force (that is, it is sprayed non-horizontally on the inner wall of the outer cylinder 100), so the residual The raw materials are rinsed away.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com