Thin-wall round tube inner hole honing fixture

A fixture and round tube technology, which is applied in the field of thin-walled round tube inner hole honing fixtures, can solve problems such as workpiece deformation, and achieve the effects of increased compressive strength, low operating power consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

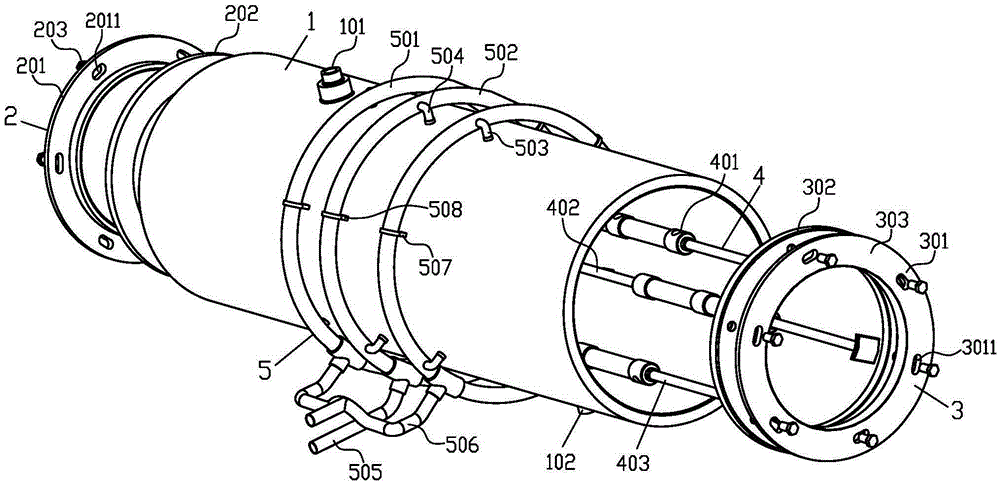

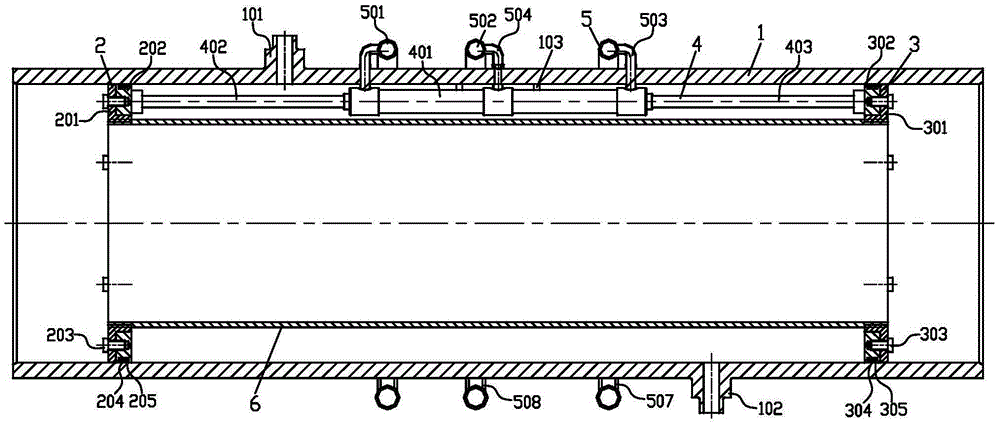

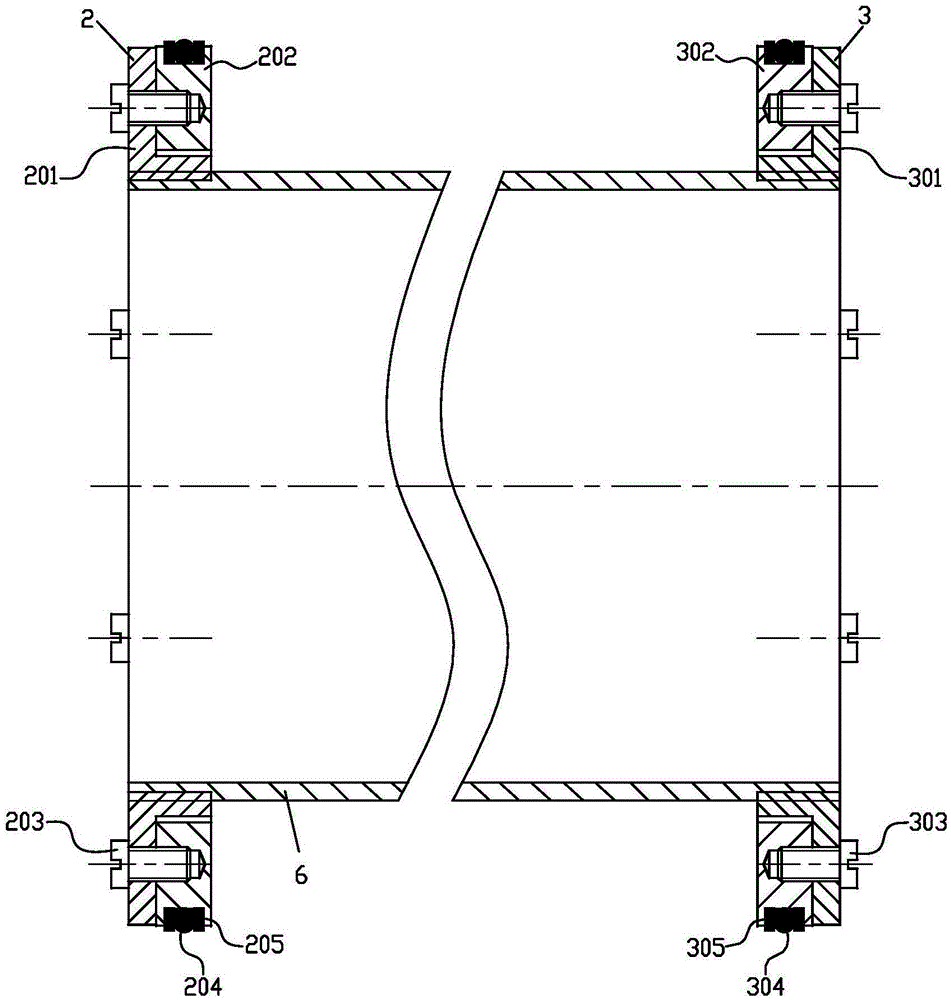

[0019] Such as figure 1 with figure 2 As shown, a thin-walled circular tube inner hole honing fixture includes a fixture body 1 , a left end cover 2 , a right end cover 3 , a driving hydraulic cylinder 4 and a piping system 5 . Wherein, a liquid inlet 101 is provided on the top of the clamp body 1, which is used to input the emulsion of a specified pressure into the closed space formed between the clamp body 1 and the outer surface of the thin-walled circular tube workpiece 6 to be processed; The bottom of the clamp body 1 is provided with a drain port 102 for discharging the emulsion in the closed space formed between the clamp body 1 and the outer surface of the processed thin-walled circular tube workpiece 6 after proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com