Aluminum bar constant-distance cutting and transporting mechanism

An aluminum rod and fixed distance technology, which is applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve the problems of high labor costs and uneven length of aluminum rods, and achieve the effect of saving labor costs and uniform length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

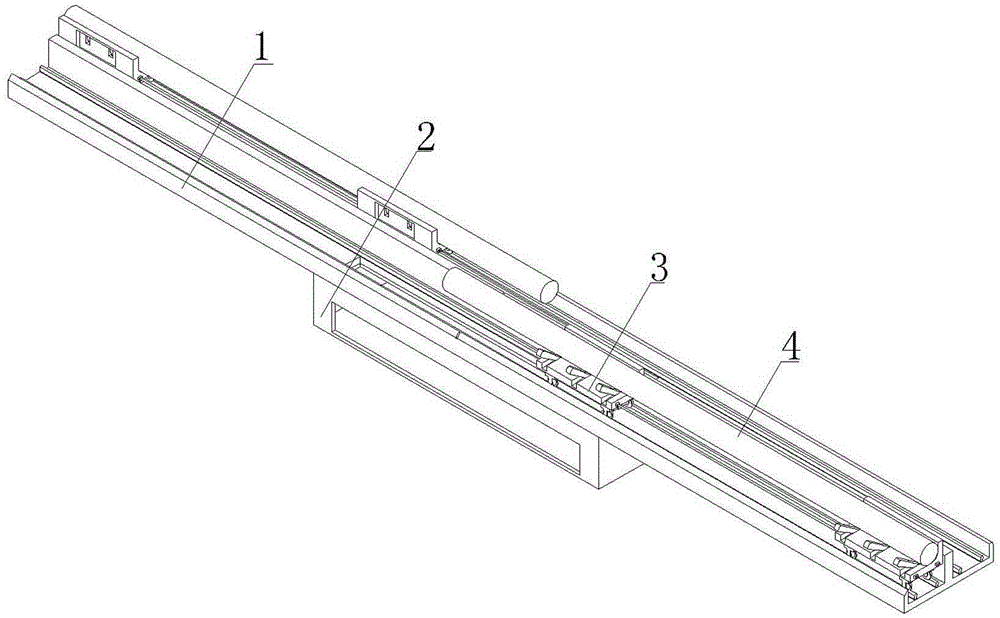

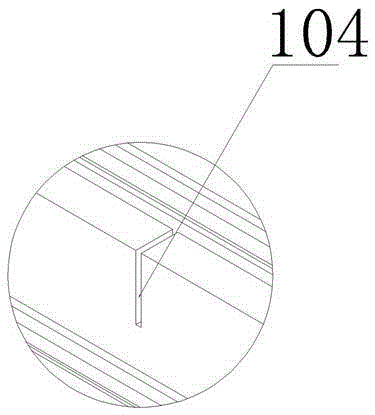

[0021] The reference signs in the accompanying drawings of the description include: base 1, track 101, partition 102, U-shaped groove 103, cutout 104, waste material groove 2, feed port 201, groove shell 202, transport trolley group 3, driven trolley 301 , gripper 302, connecting rod 303, push plate 304, inner groove 305, power trolley 306, lap brake mechanism 307, rotating shaft 308, motor 309, outer groove 310, anti-skid pattern 311, connection section 312, aluminum rod 4.

[0022] The embodiment is basically as attached Figure 1~3 As shown: the transport mechanism for aluminum bar fixed-distance cutting includes a base 1, a waste chute 2 located below the middle of the base 1, a transport trolley group 3 located on the base 1, and an aluminum bar 4 lifted by the transport trolley set 3; among them, The base 1 includes two sets of U-shaped grooves 103 arranged side by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com