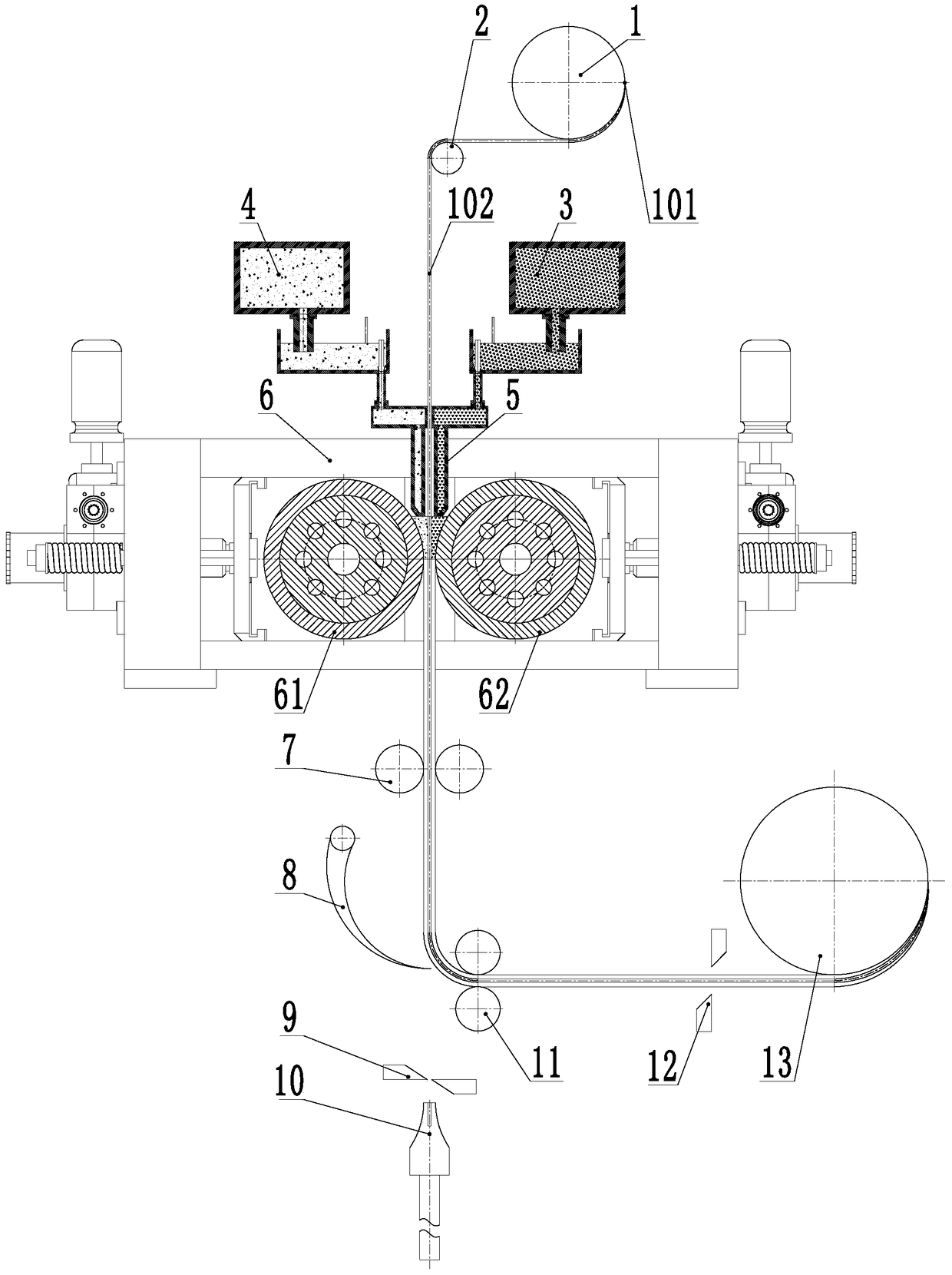

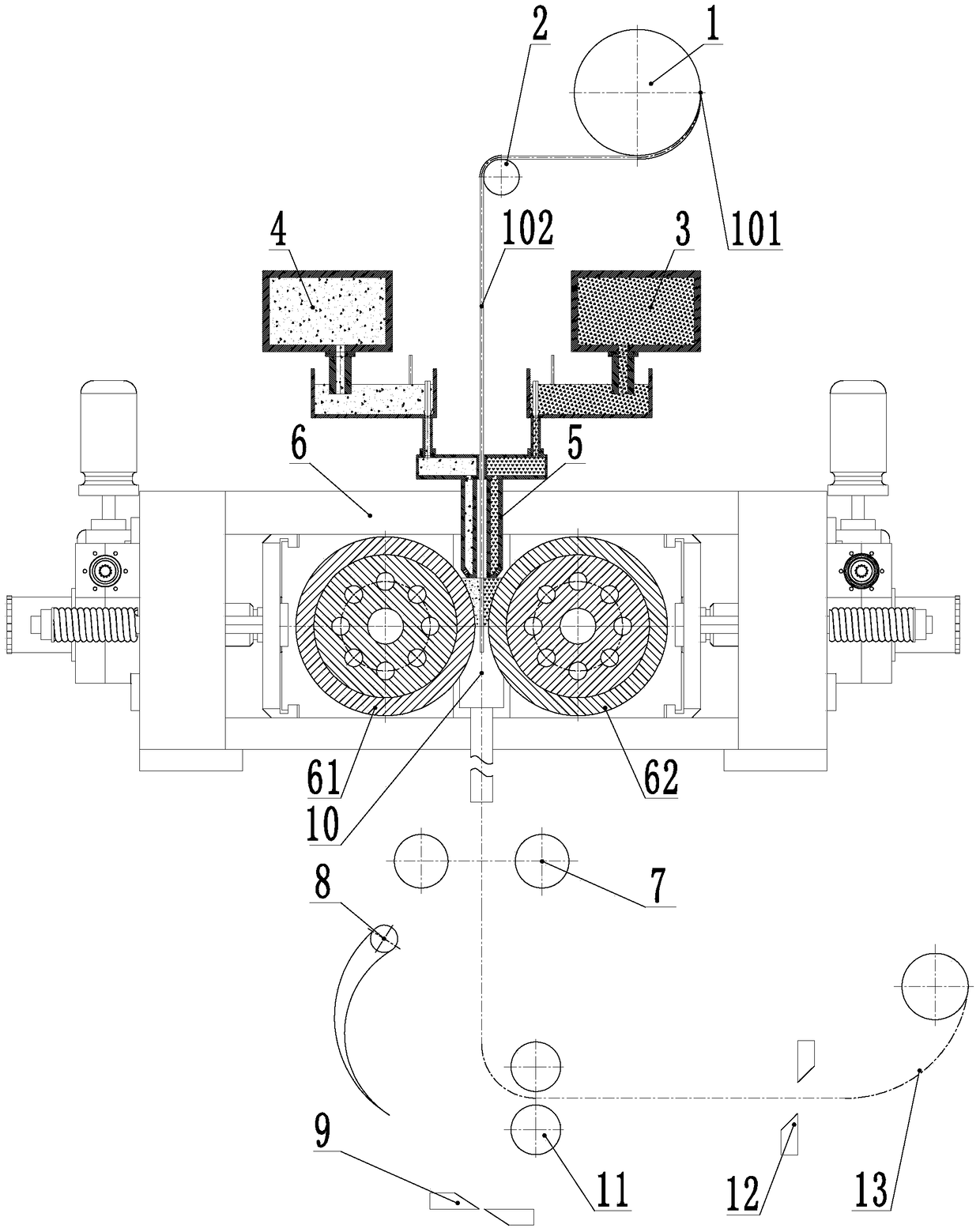

Continuous casting and rolling method for manufacturing mesh reinforced sandwich composite material by using solid-liquid casting and rolling equipment

A mesh material and equipment manufacturing technology, which is applied in the field of production equipment for mesh reinforced sandwich composite materials, can solve the problems of poor bonding quality, low productivity and high production costs, and achieve short processes, avoid mutual impact, and achieve accurate distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

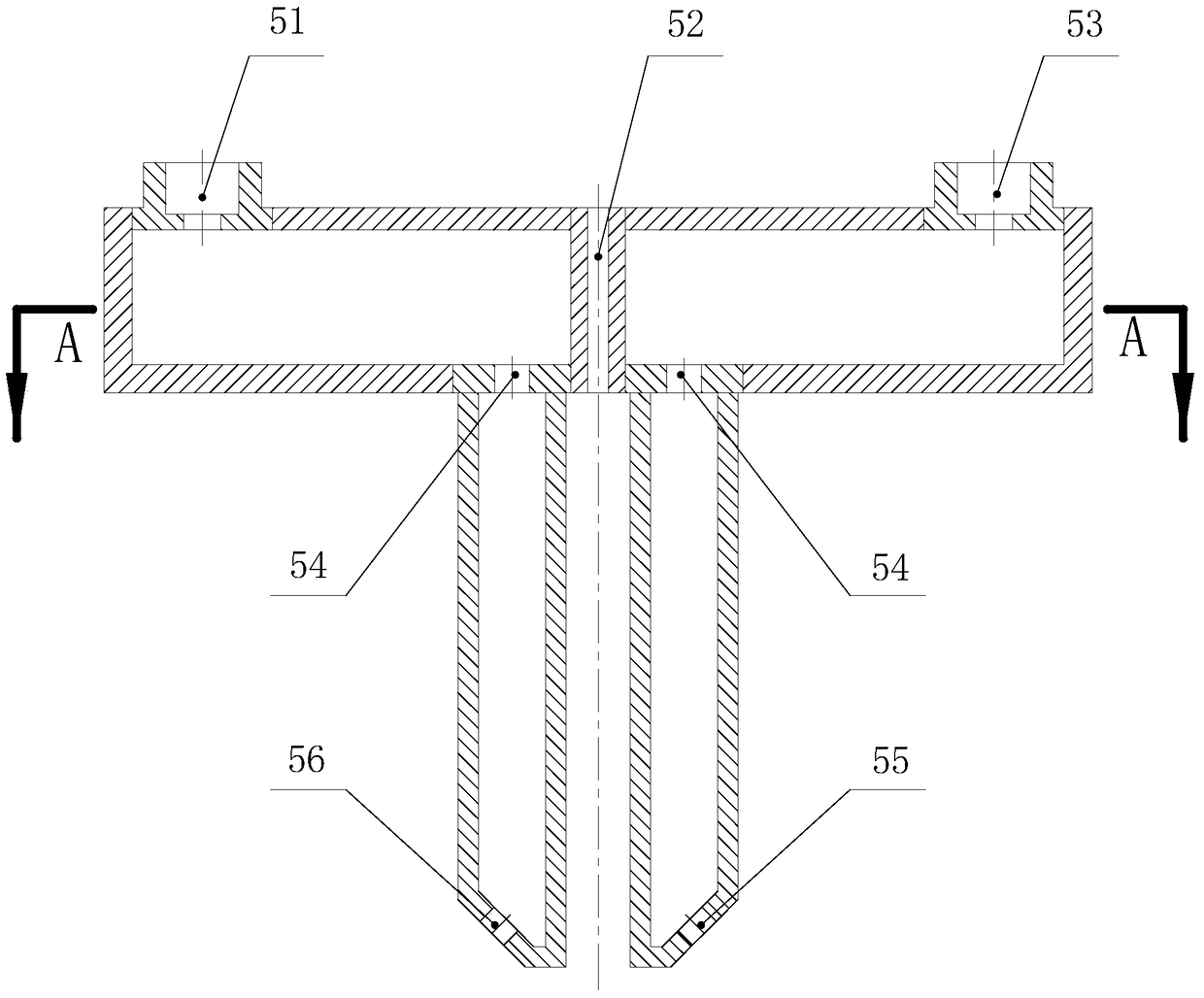

[0067] The fiber cloth 102 is a mesh carbon fiber cloth with nickel-plated surface, the carbon fiber specification is 100-3000K, the fiber cloth thickness is 0.2-1 mm, the width is 200-1200 mm, and the mesh size is 0.1-2 mm. The first metal liquid and the second metal liquid are both selected as liquid pure aluminum, and the carbon fiber reinforced aluminum matrix sandwich composite material with a product thickness of 1.5-5mm is obtained by casting and rolling, which can be used as structural parts of aerospace and other equipment to reduce weight. and electromagnetic shielding.

[0068] S1. Preheat the flow distribution and guide assembly 5 so that the inner cavity temperature reaches 500°C. Continuously inject argon gas into the central rectangular channel of the flow distribution and guide assembly as a protective gas;

[0069] S2. Roll up the mesh-shaped woven carbon fiber cloth 102 with a thickness of 0.5mm and nickel-plated surface to the uncoiler 101, and prepare the ...

Embodiment 2

[0077] The fiber cloth 102 is selected as mesh carbon fiber cloth with nickel-plated surface, the carbon fiber specification is 100-3000K, the fiber cloth thickness is 0.2-1 mm, the width is 200-1200 mm, and the mesh size is 0.1-1 mm. The first metal liquid is selected as AlMn3000 series alloy, which has good corrosion resistance. The second metal liquid is selected as AlSi4000 series alloy, which has good welding performance. The thickness of the product is 1-5mm. AlMn-carbon fiber- AlSi interlayer composite material can be used in chemical pipelines.

[0078] S1. Preheat the flow distribution and guide assembly 5 so that the inner cavity temperature reaches 500°C. Continuously inject argon gas into the central rectangular channel of the flow distribution and guide assembly as a protective gas;

[0079] S2. Roll up the net-like woven carbon fiber cloth 102 with a thickness of 0.5mm and nickel-plated surface to the uncoiler 101, and prepare the molten metal pouring devices 3 ...

Embodiment 3

[0087] Fiber cloth 102 is selected as 304 stainless steel woven wire mesh with surface cleaning treatment, and the diameter of the wire is Width 200~1200mm, mesh size 2~6mm. Both the first molten metal and the second molten metal are selected from 6061 aluminum alloy, the thickness of the product is 1-10mm, and the steel wire mesh reinforced sandwich composite material is obtained by casting and rolling.

[0088] S1. Preheat the flow distribution and guide assembly 5 so that the inner cavity temperature reaches 500°C. Continuously feed argon gas into the central rectangular channel 52 of the flow distribution and guide assembly 5 as a protective gas;

[0089] S2. Coil the 304 stainless steel wire mesh 102 with a steel wire diameter of 0.2 mm and a cleaned surface to the uncoiler 101, and prepare molten metal pouring devices 3 and 4, and keep the temperature of the aluminum alloy melt on both sides at 700°C;

[0090] S3. The stainless steel wire mesh 102 is uncoiled horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com