Gas-liquid distributing device applied to packing partition-plate rectifying tower

A gas-liquid distribution and gas distribution technology, applied in the direction of fractionation, can solve the problems of small gas and liquid two-phase flow area, high requirements for internal components of the tower, uneven distribution of rising gas and falling liquid, etc., to improve the uniformity of gas. The degree of distribution, the effect of increasing the effective flow area, and facilitating installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

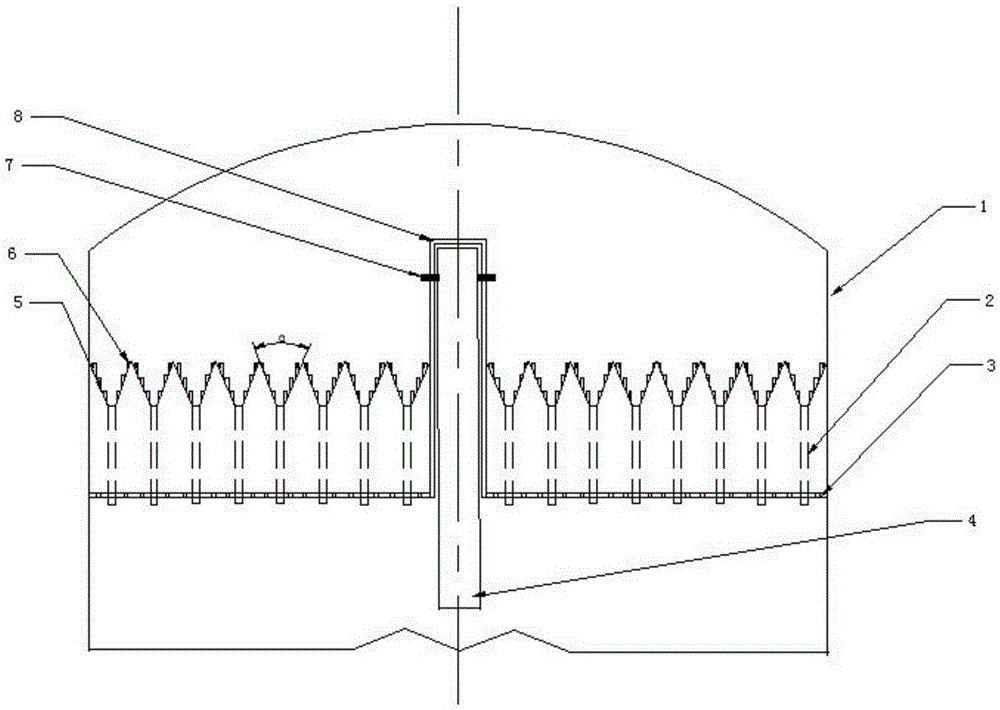

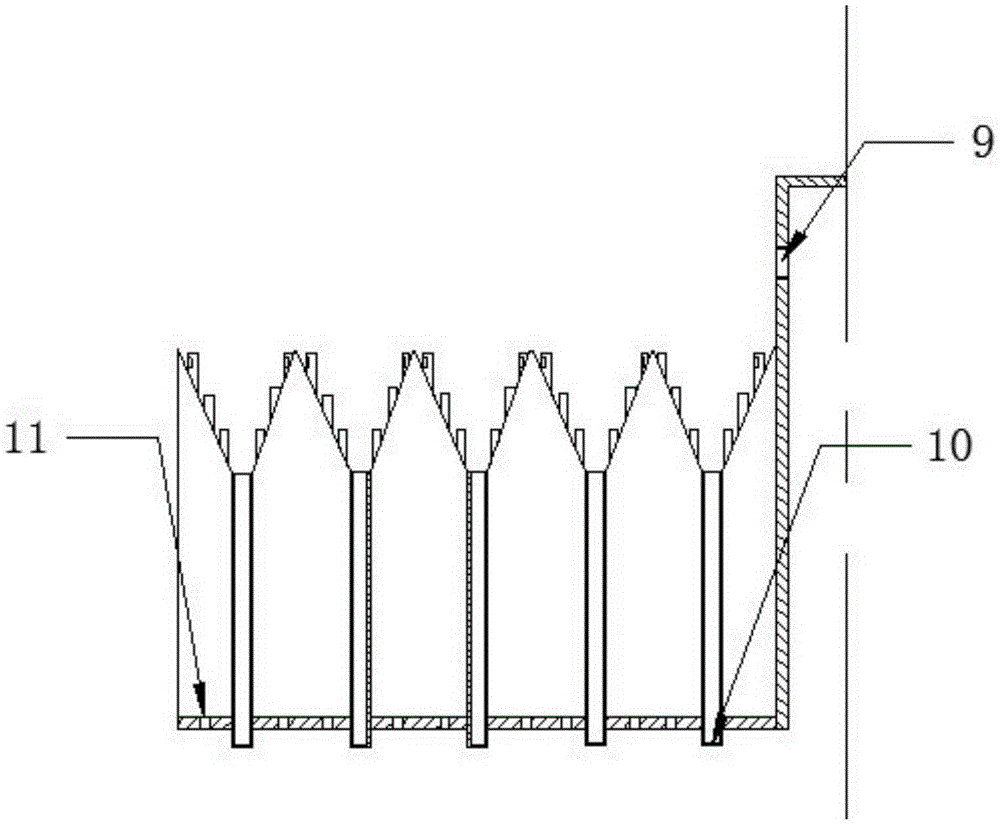

[0023] The gas-liquid distribution device of the present invention will be further described in detail in conjunction with the accompanying drawings:

[0024] like figure 1 , 2 As shown, in the new gas-liquid distribution device applied to both sides of the partition 4 in the partition rectification tower 1, the left and right are symmetrical structures, with a convex fixed structure 8 in the middle, and a V-shaped gas with round holes of different apertures. Distribution structure 5 and strip liquid distribution structure 2. The gas-liquid distribution device includes a V-shaped gas distribution structure 5 , a liquid distribution structure 2 , a convex fixed structure 8 , and a bottom plate 3 .

[0025] The V-shaped gas distribution structure 5 is installed on both sides of the partition 4 of the partition rectification tower 1, and is the upper structure of the gas-liquid distribution device, including a V-plate and a gas distribution cap 6 . The V plate is a metal steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com