Self-propelled stalk-twisting integrated harvester carrying out threshing before stalk cutting

An integrated technology that removes first and then cuts. It is applied in the direction of harvesters, threshing equipment, cutters, etc. It can solve the problems of complex structure, few hitting points, and short hitting time, so as to improve threshing efficiency, increase contact rate, and shrink effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

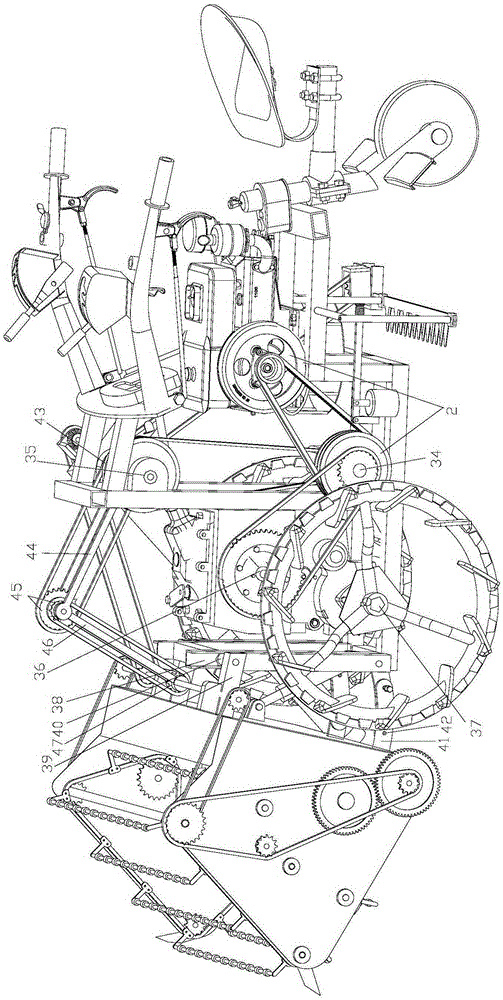

[0031] refer to figure 1 , figure 2 , the present embodiment includes a frame and a power mechanism installed thereon, a transmission mechanism, a walking mechanism, a threshing mechanism, a conveying mechanism, and a cutting mechanism. The mechanism is installed at the front of the frame, the conveying mechanism is set close to the threshing mechanism, and the cutting mechanism is installed under the frame. The power mechanism includes a prime mover 1 and a reduction device 2, and the prime mover 1 is connected to the reduction device 2; the transmission mechanism includes transmission parts, Control parts; the walking mechanism includes two walking wheels 3 and the tail wheel 4, and the two walking wheels 3 are installed at both ends of the walking wheel shaft; It includes a grain guiding chain 8, a plurality of grain guiding sprockets, and a plurality of grain pressing bars 10. The grain pressing bar 10 is fixed on the grain guiding chain 8 and circulates with the grain g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com