Planetary gear triangular rotor engine

A triangular rotor, planetary gear technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of small compression ratio, insufficient power, large volume, etc., to reduce energy loss, low fuel consumption, and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

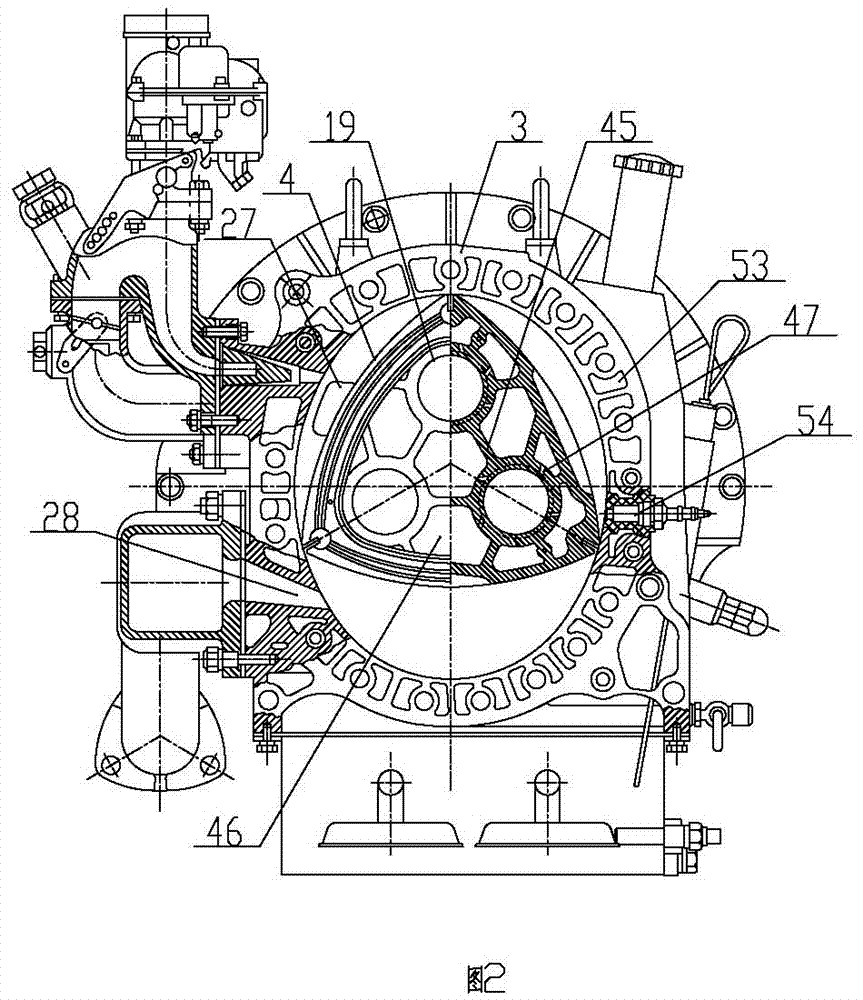

[0037] Embodiment one: as attached figure 2 Shown, the right part of cylinder block 3 is equipped with spark plug 54, and the flashover end of spark plug 54 is facing the inside of cylinder cavity and can flashover ignites the mixed gas in the combustion chamber pit 29, and the terminal of spark plug 54 is connected with the outside world by wire. The positive poles of the power supply are electrically connected together, and the cylinder block 3 is electrically connected together with the negative poles of the external power supply through wires. When the present invention is a gasoline engine, it is necessary to ignite the mixed gas in the pit 29 of the combustion chamber through the timing flashover of the spark plug 54 .

Embodiment 2

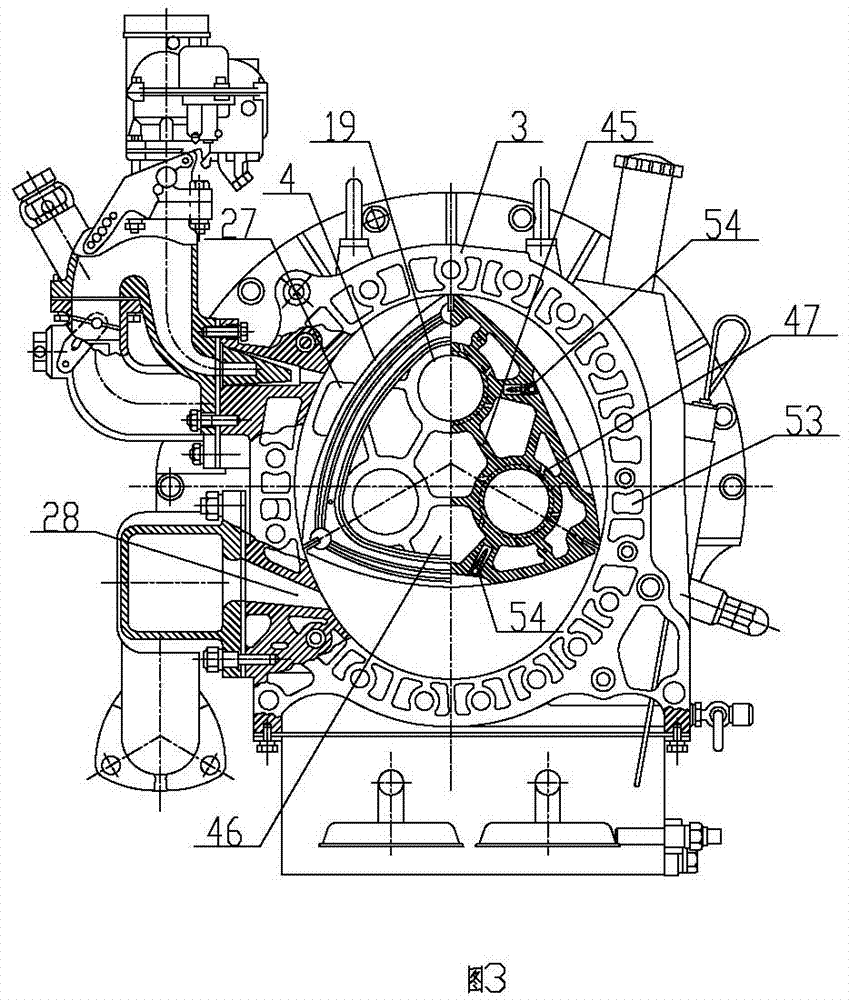

[0038] Embodiment two: as attached image 3 As shown, spark plugs 54 are respectively installed on each arc surface of the triangular rotor 4, and the flashover end of the spark plug 54 is located in the combustion chamber pit 29 and can flash over and ignite the mixed gas in the combustion chamber pit 29, and the terminal of the spark plug 54 The positive pole of the external power supply is electrically connected through wires, carbon brushes and ignition coils, and the cylinder block 3 is electrically connected with the negative pole of the external power supply through wires. By installing the spark plug 54 on each arc surface of the triangular rotor 4, when each arc surface rotates to the right part of the cylinder block 3 in turn, the terminal of the spark plug 54 is connected to the high voltage circuit instantaneously through the carbon brush and the cylinder block 3 to cause flashover , ignite the mixed gas in the corresponding combustion chamber pit 29 at this time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com