Stainless steel surface treatment method and stainless steel watch shell

A surface treatment, stainless steel technology, applied in surface reaction electrolytic coating, superimposed layer plating, anodizing and other directions, can solve the problem of poor adhesion between aluminum plating layer and stainless steel substrate, time-consuming ion plating thick film, and increasing process Cost and other issues, to shorten the hot dip plating time, overcome the harm to the human body and the environment, and improve the surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) The stainless steel workpiece is pretreated by polishing, cleaning and degreasing. The stainless steel workpiece in this embodiment is the base body of the stainless steel watch case.

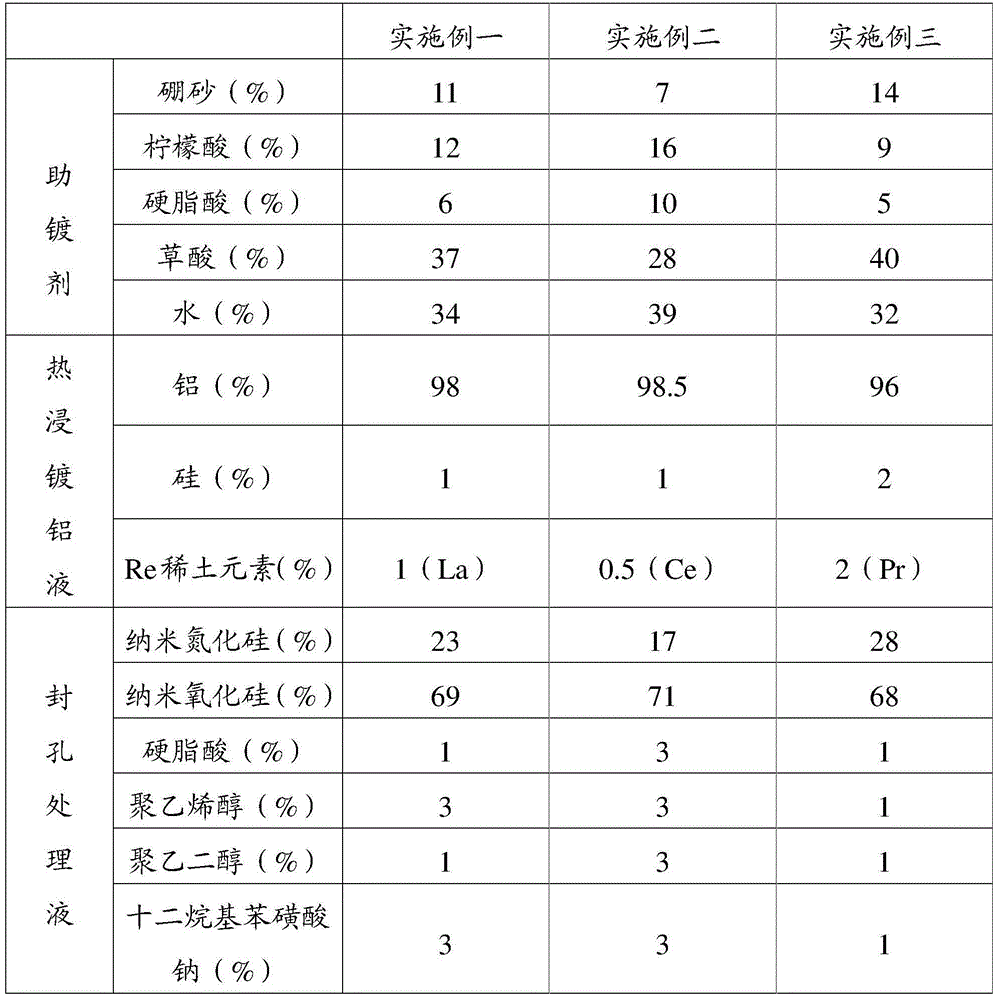

[0051] 2) Ultrasonic assisted plating treatment: immerse the pretreated stainless steel workpiece in a plating flux solution (see Table 1 for the formulation of the flux solution), perform plating flux treatment with ultrasonic vibration, and then dry it. The specific process parameters are: the plating flux treatment temperature is 70°C, the plating flux treatment time is 4 minutes, the ultrasonic vibration frequency is 100KHz, the power is 500W, the drying temperature is 300°C, and the drying time is 6 minutes.

[0052] 3) Ultrasonic-assisted hot-dip aluminizing: immerse the stainless steel workpiece after the electroplating treatment into the hot-dip aluminizing solution (see Table 1 for the formula of the hot-dip aluminizing solution) and perform ultrasonic-assisted hot-dip alumin...

Embodiment 2

[0058] 1) The stainless steel workpiece is pretreated by polishing, cleaning and degreasing.

[0059] 2) Ultrasonic assisted plating treatment: immerse the pretreated stainless steel workpiece in a plating flux solution (see Table 1 for the formulation of the flux solution), perform plating flux treatment with ultrasonic vibration, and then dry it. The specific process parameters are: the plating flux treatment temperature is 90°C, the plating flux treatment time is 2 minutes, the ultrasonic vibration frequency is 80KHz, the power is 500W, the drying temperature is 240°C, and the drying time is 10 minutes.

[0060] 3) Ultrasonic-assisted hot-dip aluminizing: immerse the stainless steel workpiece after the electroplating treatment into the hot-dip aluminizing solution (see Table 1 for the formula of the hot-dip aluminizing solution) and perform ultrasonic-assisted hot-dip aluminizing treatment by ultrasonic vibration. Among them, the hot dipping temperature is 700°C, and the dipp...

Embodiment 3

[0066] 1) The stainless steel workpiece is pretreated by polishing, cleaning and degreasing.

[0067] 2) Ultrasonic assisted plating treatment: immerse the pretreated stainless steel workpiece in a plating flux solution (see Table 1 for the formulation of the flux solution), perform plating flux treatment with ultrasonic vibration, and then dry it. The specific process parameters are: the plating flux treatment temperature is 70°C, the plating flux treatment time is 4 minutes, the ultrasonic vibration frequency is 100KHz, the power is 500W, the drying temperature is 320°C, and the drying time is 4 minutes.

[0068] 3) Ultrasonic-assisted hot-dip aluminizing: immerse the stainless steel workpiece after the electroplating treatment into the hot-dip aluminizing solution (see Table 1 for the formula of the hot-dip aluminizing solution) and perform ultrasonic-assisted hot-dip aluminizing treatment by ultrasonic vibration. Among them, the hot dipping temperature is 750°C, and the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com