Water purifier special for novel water drinking machine

A water dispenser and water purifier technology, which is applied in the field of new water dispenser special water purifiers, can solve the problems of low volume utilization rate of water purifiers, short contact time between raw water and granular activated carbon, waste of resources, etc., so as to save water treatment materials. The effect of easy guarantee of resources and effluent quality and high effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

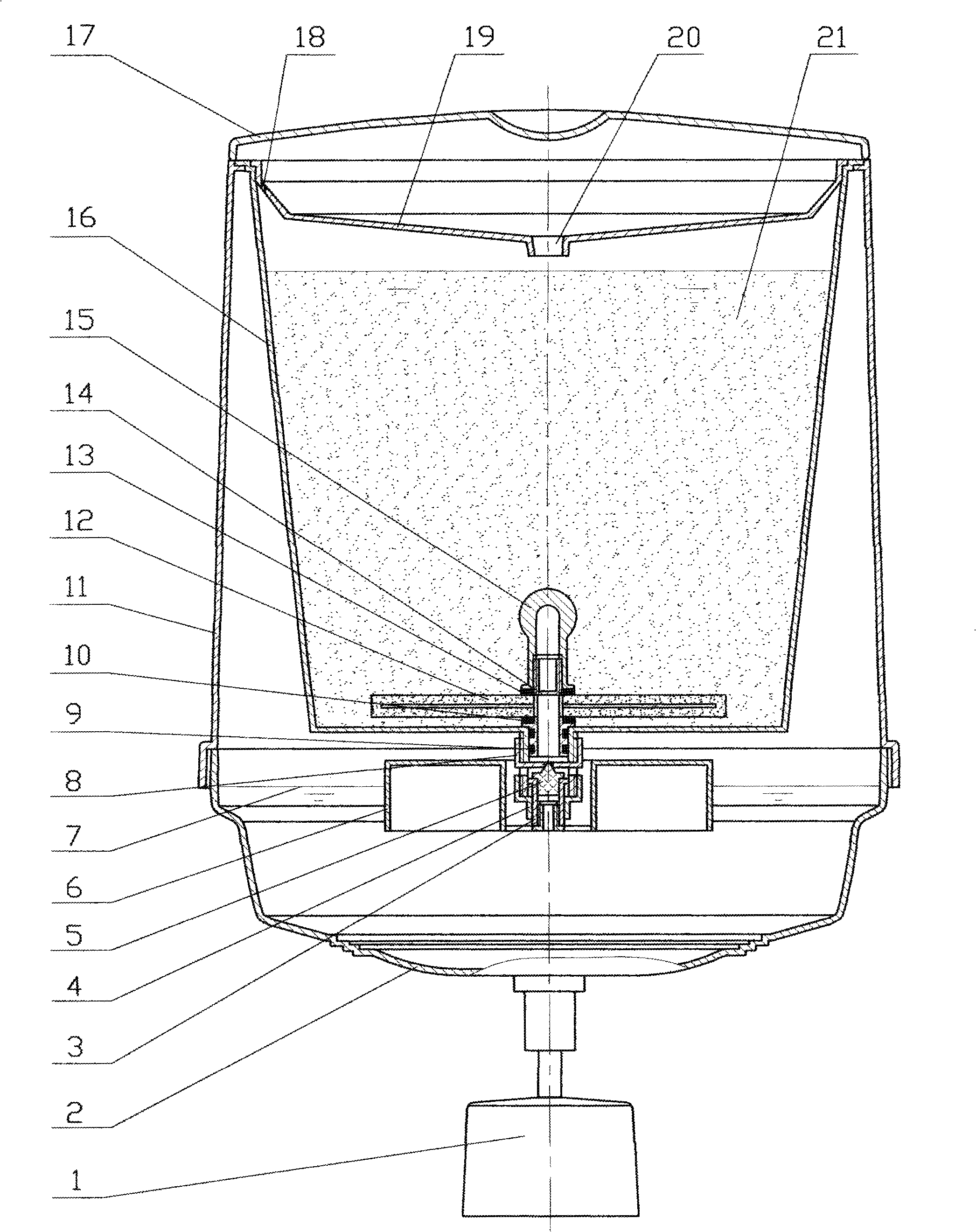

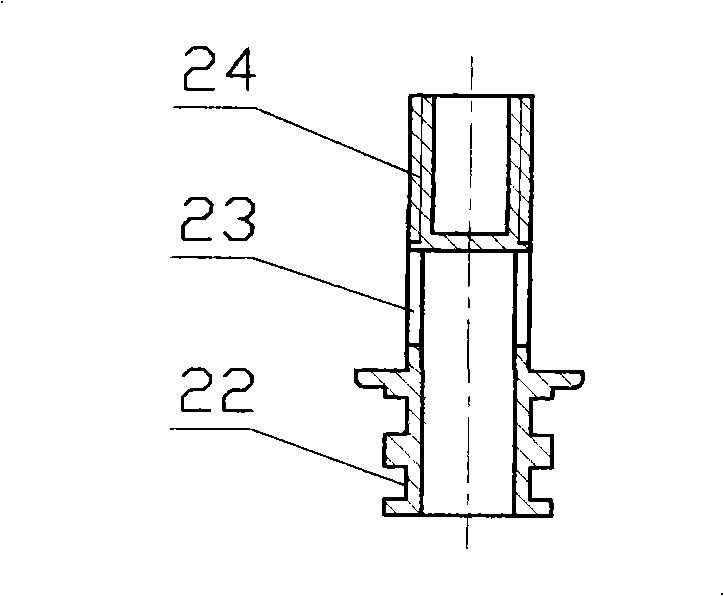

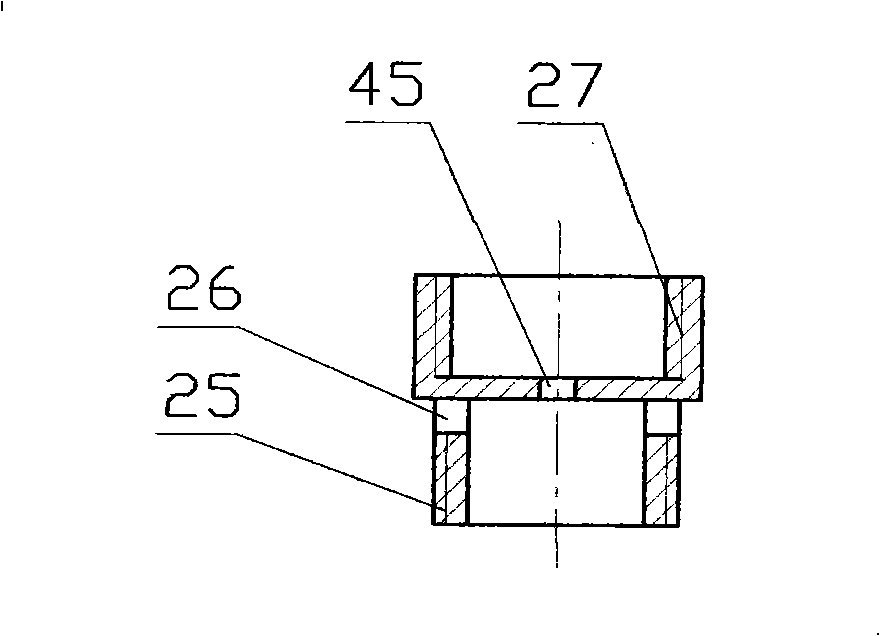

[0053] Example 1: Combining figure 1 , figure 2 , image 3 with Figure 4 As shown, the special water purifier of the novel water dispenser of the present embodiment comprises a former water bucket (16), a clean water bucket (2), a microporous ceramic filter element, a water purifier cover (17), an upper float valve and a lower float valve ( 1); the upper float valve is placed in the clean water bucket (2) to control the highest water level in the clean water bucket (2); the lower float valve (1) is connected to the water outlet at the bottom of the clean water bucket (2), Its float extends down into the water bucket of the water dispenser, and is used to control the highest water level in the water bucket of the water dispenser; the original water bucket (16) is arranged on the top of the water purification bucket (2) and is supported by the water purifier housing (11) , the water purifier housing (11) is supported on the clean water barrel (2); the top of the original w...

Embodiment 2

[0057] Embodiment 2: Combination Figure 5 As shown, the special water purifier of the novel water dispenser of the present embodiment includes a raw water bucket, a clean water bucket (2) and a high-precision single-sided filter microporous ceramic filter element; 33), the barrel body (37) and the bottom plate (33) are bonded to make the two into one, and the joint adopts a tenon-groove structure, that is, the barrel body (37) is provided with a tenon, and the bottom plate (33) is provided with a groove; The single-side filtering microporous ceramic filter element is composed of a single-side filtering microporous ceramic (36) and a "Z" ring (35), and the single-side filtering microporous ceramic (36) and the "Z" ring (35) The space is fixed by silicone rubber bonding; the "Z" shaped ring (35) and the bottom plate (33) are sealed by an "O" shaped sealing ring (34); the center of the bottom plate (33) is provided with a water outlet. A short pipe extends downwards at the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| filtration accuracy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com