A method for selective hydrodearomatization of inferior diesel oil

A technology for hydrodearomatization and low-quality diesel oil, which is applied in the fields of aromatics hydrorefining, petroleum industry, refined hydrocarbon oil, etc. It can solve the problem of poor selectivity of single-ring aromatics, improve the selectivity of single-ring aromatics, and reduce processing costs , Improve the effect of process economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

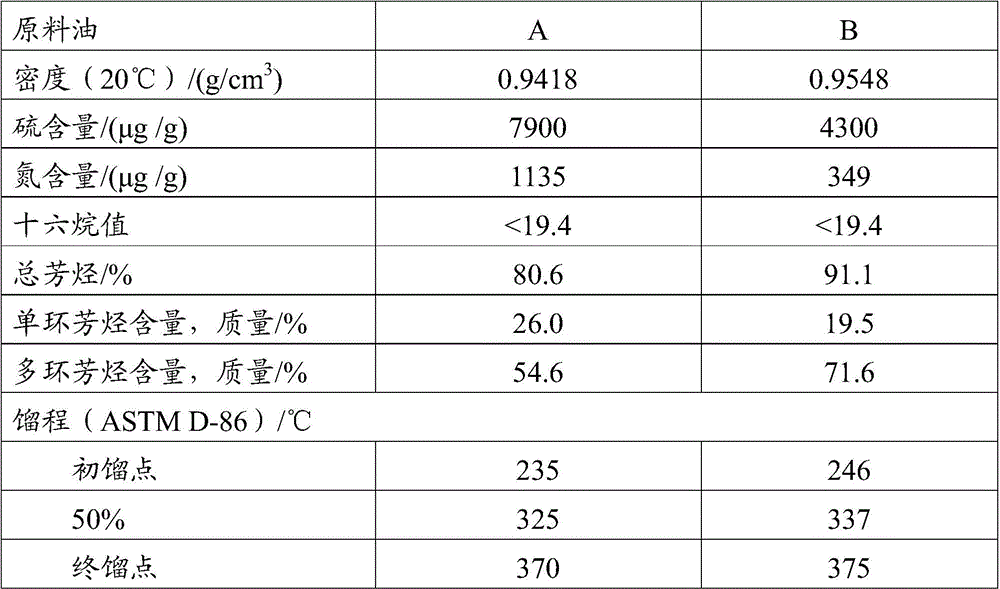

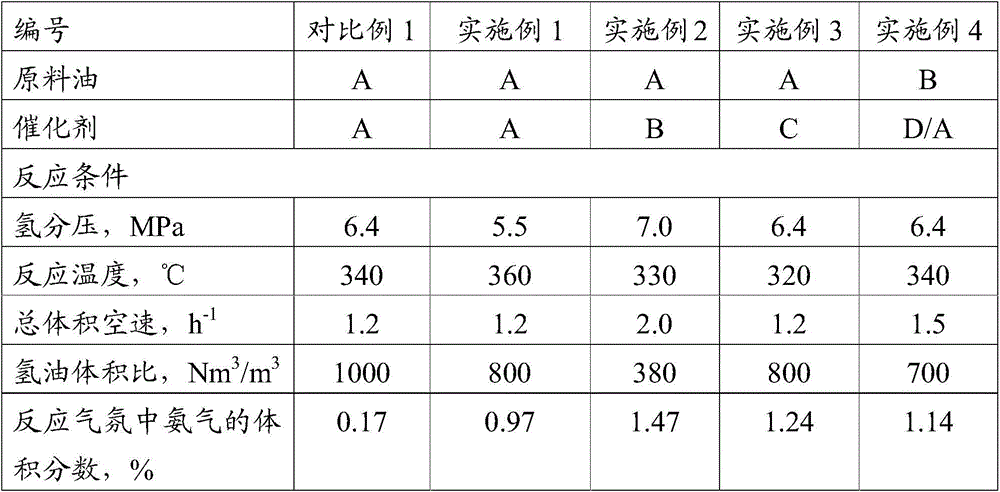

[0056] The raw material oil A and the feed mixture of hydrogen enter the hydrofinishing reactor together, contact and react with the hydrofinishing catalyst A, and add ammonia gas to the feed mixture, based on the raw material oil A, its addition amount is 0.50% by weight, The reaction effluent enters the high-pressure separator for gas-liquid separation to obtain hydrogen-rich gas and hydrogenated oil. The reaction conditions are shown in Table 2, and the hydrocarbon composition of the hydrogenated oil is shown in Table 3.

[0057] As can be seen from Table 3, the removal rate of polycyclic aromatics in the hydrogenated oil is 80.4%, the removal rate of the total aromatics is 19.4%, and based on the hydrogenated oil, the content of single-ring aromatics is 54.3% by mass , the selectivity of single-ring aromatics is 64.4%, compared with the selectivity of single-ring aromatics in Comparative Example 1, it has increased by 38.5%. The nitrogen content in the hydrogenated oil wa...

Embodiment 2

[0059] The raw material oil A and the feed mixture of hydrogen enter the hydrofinishing reactor together, contact and react with the hydrofinishing catalyst B, add ammonia and pyridine to the raw material mixture, based on the raw material oil A, add The content of ammonia gas is 0.25% by weight, the content of added pyridine is 0.35% by weight, and the reaction effluent enters a high-pressure separator for gas-liquid separation to obtain hydrogen-rich gas and hydrogenated oil. The reaction conditions are shown in Table 2, and the hydrocarbon composition of the hydrogenated oil is shown in Table 3.

[0060] As can be seen from Table 3, the removal rate of polycyclic aromatics in the hydrogenated oil is 85.1%, the removal rate of the total aromatics is 18.6%, and based on the hydrogenated oil, the content of single-ring aromatics is 59.0% by mass , the selectivity of single-ring aromatics is 68.8%, compared with the selectivity of single-ring aromatics in Comparative Example 1,...

Embodiment 3

[0062] The raw material oil A and the feed mixture of hydrogen enter the hydrofinishing reactor together, contact and react with the hydrofinishing catalyst C, and add sec-butylamine to the feed mixture, based on the raw material oil A, its addition amount is 3.0% by weight , the reaction effluent enters the high-pressure separator for gas-liquid separation to obtain hydrogen-rich gas and hydrogenated oil. The reaction conditions are shown in Table 2, and the hydrocarbon composition of the hydrogenated oil is shown in Table 3.

[0063] As can be seen from Table 3, the removal rate of polycyclic aromatics in hydrogenated oil is 90.2%, the removal rate of total aromatics is 24.3%, and based on hydrogenated oil, the content of single-ring aromatics is 62.0% by mass , the selectivity of single-ring aromatics is 65.9%, compared with the selectivity of single-ring aromatics in Comparative Example 1, it has increased by 40.0%. The nitrogen content in the hydrogenated oil was 10 μg / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com